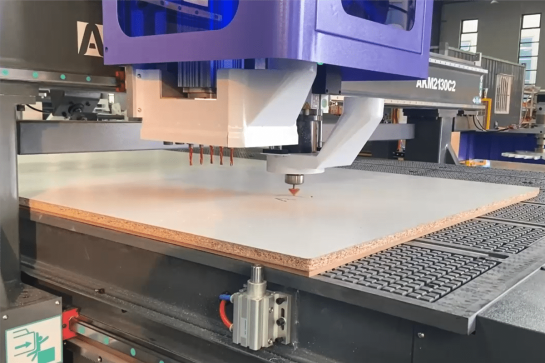

Industrial CNC Router

The industrial CNC router is a sophisticated computer-controlled cutting machine designed for precision and efficiency in various manufacturing processes. It utilizes Computer Numerical Control (CNC) technology to interpret design specifications and translate them into precise movements of the CNC router’s cutting tool. Industrial CNC routers are widely used in industries such as woodworking, metalworking, and plastic fabrication to cut, shape, and engrave materials with high accuracy.

The industrial CNC router is equipped with powerful motors and advanced control systems that can flexibly handle a variety of materials, including wood, aluminum, composites, and plastics. Equipped with a spindle that accommodates a variety of cutting tools, it is capable of executing complex designs with incredible precision, reducing material waste and human error. Industrial CNC routers enable manufacturers to achieve complex designs and shapes with consistent quality and are therefore widely used in areas such as mass production, prototyping, and custom manufacturing.

Tips For Choosing The Right Industrial CNC Router

Embarking on the journey to purchase an industrial CNC router requires careful evaluation of specific needs and features. We provide valuable insights into key considerations such as application requirements, machine specifications, and support services. Whether you’re an experienced manufacturer or new to exploring CNC technology, we’ll guide you through essential tips so you can make informed decisions and choose the perfect CNC router for your industrial needs.

Application Requirements

Start by thoroughly understanding your processing needs. Determine the specific materials and applications you will be using, whether wood, metal, plastic, or a combination thereof. Different CNC routers are optimized for specific tasks and are needed to align the machine’s capabilities with your application requirements.

Machine Dimensions And Working Area

Consider the size of your project and the size of the materials you will be working with. Make sure the CNC router’s work area can accommodate the largest workpiece you anticipate using. Evaluate the machine’s load capacity to ensure it can handle your production volume without compromising accuracy.

Spindle Power And Speed

Evaluate the spindle’s power and speed capabilities. Higher horsepower helps cut dense materials, while variable speed options provide flexibility for different tooling requirements. Match these specifications to the needs of your specific application to ensure optimal performance.

Precision And Accuracy

Precision is crucial in CNC machining. Check the machine’s accuracy, repeatability, and resolution specifications. Look for features like ball screws, high-quality linear guides, and advanced motion control systems to help achieve tight tolerances and consistent results on a variety of projects.

Control System

Check the control system and its compatibility with existing CAD/CAM software. A user-friendly interface, intuitive controls, and software compatibility help seamlessly integrate the machine into your production workflow.

Tools And Compatibility

Check tool options for availability and compatibility. Expand your capabilities with a versatile CNC router that supports a variety of tool types. Depending on your application requirements, consider whether the machine can accommodate different tool diameters and types.

Construction And Durability

Check the structure of the CNC router and the materials used. The sturdy and durable frame ensures stability during operation, minimizing vibrations that can affect accuracy. Consider features like cast iron or steel construction for longevity and stability, especially if the machine is going to be used heavy-duty.

Easy To Maintain

Evaluate the ease of maintenance and accessibility of daily tasks. Choose a CNC router designed to simplify cleaning, lubrication, and general maintenance. Easy access to critical components aids in troubleshooting and minimizes downtime during repairs.

Support And Service

Investigate the level of customer support provided by the manufacturer or supplier. Make sure they provide comprehensive training for your team. Also, check to see if there is ready documentation and responsive support to resolve technical issues and provide assistance.

Budget Considerations

Create a realistic budget based on your business’s financial capabilities. Compare the features offered by different CNC routers within your budget. Consider long-term value and potential return on investment, ensuring the machine you select meets your immediate needs and allows for future growth.

Future Expansions And Upgrades

Anticipate future needs and evaluate CNC router expansion and upgrade potential. Choose machines with modular components that can be easily upgraded or expanded to meet changing business needs. This ensures your investment can adapt to technological advances and changing production needs.

Comments And Suggestions

Seek feedback from industry peers and read reviews on the specific CNC router model you are considering. Real-world experience can provide valuable insights into the performance, reliability, and user satisfaction of different machines. Consider both positive and negative reviews to make a thorough evaluation.

What Materials Can An Industrial CNC Router Cut?

The industrial CNC router is a versatile tool capable of cutting a wide range of materials with precision. The specific materials a CNC router can cut depend on factors such as the machine’s power, spindle speed, and the type of cutting tools used. Common materials include:

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Aluminum

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

How to Reduce the Impact of Workpiece Adhesion on CNC Router Cutting Quality

This article delves into practical strategies for mitigating the impact of workpiece adhesion on CNC router cutting quality, to improve the performance and reliability of CNC router operations.

Read More

Addressing Environmental Concerns in CNC Router Waste Disposal: A Comprehensive Guide

In this article, we delve into the considerations for the correct disposal of waste materials from CNC router operations, aiming to tackle the environmental challenges posed by CNC waste.

Read More

Guide to Optimizing CNC Router Parameters for Diverse Materials

This article provides a systematic parameter optimization method for CNC routers cutting different materials, aiming to provide users with the necessary knowledge to achieve excellent processing quality.

Read More

Understanding the Perils of Spindle Runout in CNC Routers

This article delves into the causes of spindle runout and strategies for mitigating its effects, aiming to provide you with the knowledge to optimize CNC router performance.

Read More

Mastering CNC Router Worktables: A Comprehensive Guide

This article delves into the CNC router types, operating methods, maintenance, and customization options, providing you with the knowledge to optimize your CNC router settings for superior results.

Read More

CNC Router Bits: Complete Buyer’s Guide

From understanding the different types of CNC router bits to deciphering the nuances of materials and coatings, this guide provides the essential reference for finding the right bit for your ...

Read More

Frequently Asked Questions

What is an industrial CNC router?

The industrial CNC router is a complex automated machining tool used in manufacturing and fabrication processes. This precision equipment operates under computer guidance to perform complex cutting, engraving, milling, and carving tasks on a variety of materials.

Key components of an industrial CNC router include a control system driven by specialized software, a spindle that houses the cutting tool, a stable work surface, and a complex drive system that can move along multiple axes.

Industrial CNC routers are known for their high accuracy, repeatability, and efficiency in converting digital designs (often created in CAD software) into physical products or components. It’s suitable for woodworking, metalworking, signage, prototyping, and more, meeting the needs of every industry. Industrial CNC routers simplify the production process and enable complex designs to be produced with extremely high precision while significantly reducing production time and material waste. Its adaptability and precision make it indispensable in modern manufacturing and manufacturing.

What industries are industrial CNC routers used in?

Industrial CNC routers are widely used in various industries because of their versatility and precision. Some important industries where CNC routers are widely used include:

- Carpentry: Making furniture, cabinets, doors, and intricate woodwork.

- Metalworking: Shaping and cutting metal parts for a variety of applications.

- Plastic Manufacturing: Cutting, milling, and forming plastic materials for products such as prototypes, molds, and signs.

- Aerospace: Machined components for aircraft, spacecraft, and related structures.

- Automotive: Manufacturing vehicle parts and prototypes.

- Signage: Cutting and engraving materials used in sign making and display making.

- Electronics Manufacturing: Creating custom components for electronic devices.

- Packaging: Create custom packaging solutions with intricate designs and precise cutting.

- Construction: Manufacturing of building elements, molds, and assemblies for construction projects.

- Art and Sculpture: Create intricate sculptures and artistic designs.

- Education: Used in educational settings for training and teaching purposes in engineering and design.

- Medical: Produces custom medical devices, components, and prototypes.

- Textiles and Apparel: Precision cutting of fabrics and materials for the textile and apparel industry.

- Stone Cutting: Carving and cutting stone for architectural applications, monuments, and art.

What is the difference between a desktop CNC router and an industrial CNC router?

The main differences between desktop CNC routers and industrial CNC routers are their size, functionality, and intended use. Here are the main differences between the two:

- Dimensions And Footprint

- Desktop CNC Router: Typically smaller and designed to be mounted on a desktop or workbench. These machines are more compact and suitable for smaller workshops or hobbyists.

- Industrial CNC Router: Larger and stronger. Designed for industrial environments, these machines feature larger work areas to accommodate a wider range of materials and larger projects.

- Cutting Ability

- Desktop CNC Router: Ideal for smaller projects and materials due to limited cutting area and less powerful spindle.

- Industrial CNC Router: Able to handle larger, denser materials. Equipped with a more powerful spindle for efficient cutting of various materials on an industrial scale.

- Structure And Stiffness

- Desktop CNC Router: Typically made from lighter materials to maintain portability. The frame may be less rigid than its industrial counterpart.

- Industrial CNC Router: Made of heavy-duty materials such as cast iron or steel, providing greater rigidity and stability. Achieve consistent and precise cuts even in demanding industrial production processes.

- Power And Speed

- Desktop CNC Router: Typically has lower power and speed capabilities. Ideal for lighter cutting tasks and hobby projects.

- Industrial CNC Router: equipped with higher power spindle and faster cutting speed. Able to handle the heavy cutting and machining operations required in industrial production.

- Accuracy And Precision

- Desktop CNC Router: Provides good accuracy for small projects, but may have limitations in achieving the same level of accuracy as industrial machines.

- Industrial CNC Router: Designed for high accuracy and repeatability. These machines can maintain tight tolerances at all times, making them suitable for demanding industrial applications.

- Tool Changers And Automation

- Desktop CNC Routers: Typically lack automatic tool-changing systems. Tool changes may require manual intervention, limiting efficiency.

- Industrial CNC Router: Many industrial models are equipped with automatic tool changers, allowing seamless transitions between different tools during machining, which increases efficiency and productivity.

- Cost

- Desktop CNC Router: Typically less expensive than industrial mills, suitable for hobbyists and small businesses.

- Industrial CNC Router: Requires a higher upfront investment due to its larger size, greater functionality, and rugged construction. However, efficiency and production capabilities often justify the cost of industrial applications.

- Application Scope

- Desktop CNC Router: Ideal for prototyping, small-scale production, and hobbyist projects. There may be limitations in handling larger or more complex industrial tasks.

- Industrial CNC Router: Customized for high-volume production, manufacturing, and applications that require precision, speed, and the ability to handle diverse and challenging materials.

What is the cost of an industrial CNC router?

The cost of an industrial CNC (Computer Numerical Control) router can vary widely, ranging from approximately $10,000 to several hundred thousand dollars, depending on factors such as size, capabilities, brand, and additional features. Entry-level industrial CNC routers, suitable for specific applications, may start at around $6,000 to $15,000. Mid-range models, offering larger cutting areas, higher precision, and additional features, can range from $15,000 to $30,000. High-end or specialized industrial CNC routers, equipped with advanced technology and extensive cutting capabilities, may exceed $50,000 and reach into the upper echelons of the price spectrum.

Several factors influence the cost, including the size of the machine, tooling and accessories, brand reputation, build quality, and the sophistication of control systems and software. Additional expenses for installation, training, and maintenance should also be considered. Customization and specialized requirements may contribute to variations in the overall cost. Potential buyers need to consult with manufacturers or suppliers to obtain accurate quotes tailored to their specific needs, ensuring a well-informed investment in a CNC router that meets their industrial machining requirements.

Can the industrial CNC router be customized to meet specific needs?

Yes, industrial CNC routers can often be highly customized to meet specific needs and requirements. AccTek CNC offers a range of options and configurations to customize the machine to the precise specifications of the individual user or industry. Here are some common customization options:

- Work Area Dimensions: Industrial CNC routers can be customized with larger or smaller work areas to accommodate specific material sizes and project requirements.

- Spindle Options: Industrial CNC routers can be equipped with different spindle options based on power, speed, and tool compatibility to meet specific material-cutting requirements.

- Tool Options: Depending on the application, the machine can be configured to support a variety of tool options, such as different types of milling cutters, end mills, or specialized tools.

- AutomaticTool Changer: Industrial CNC routers can be equipped with automatic tool changers, allowing multiple tools to be used in one job without manual intervention.

- Control Systems And Software: Users can select or customize CNC control systems and software to match their preferred workflow and compatibility with existing CAD/CAM systems.

- Vacuum Tables And Workpiece Holding Systems: Customized options for workpiece holding systems, including vacuum tables, jigs, or fixtures, enable users to efficiently hold different types of materials.

- Enclosures And Safety Features: Customized safety features such as additional enclosures, emergency stop systems or safety sensors can be integrated for enhanced operator protection.

- Dust Removal System: Industrial CNC routers can be equipped with customized dust removal systems to effectively manage and extract dust and debris generated during cutting operations.

- Automation And Integration: Integration with robotic systems, conveyors, or other automation solutions can be customized to streamline material handling and increase overall production efficiency.

- Enhanced Accuracy Capabilities: Higher accuracy, precision-enhanced custom upgrades, or specialized measurement systems can be incorporated for applications requiring tight tolerances.

What is the expected lifespan of the industrial CNC router?

The expected service life of an industrial CNC router can vary widely based on a variety of factors, including the machine’s build quality, intensity of use, maintenance, technological advancements, and industry standards. Generally speaking, industrial-grade CNC routers are designed to operate continuously for several years, and the average lifespan is usually 10 to 20 years or more.

Key factors affecting the service life of industrial CNC routers include:

- Build Quality: CNC routers made from durable materials like cast iron or steel tend to have a longer lifespan. High-quality components contribute to overall stability and longevity.

- Maintenance And Care: Regular maintenance, including cleaning, lubrication, and timely repairs, will significantly affect the service life of the machine. Proper maintenance can extend the service life of your CNC router and ensure stable performance.

- Intensity of Use: Frequency and intensity of use have an impact. Machines used in heavy-duty, continuous production environments are likely to experience more wear and tear than machines used intermittently on smaller projects.

- Technological Advances: Rapid technological advancements can render older CNC routers obsolete. Upgrades or retrofits may be options to expand machine capabilities, but at some point, technological changes may require new investment.

- Manufacturer And Brand: Reputable manufacturers that prioritize quality and reliability will typically produce machines that last longer. Choosing a trustworthy brand will affect the overall durability of your CNC router.

- Upgrades And Modifications: Some machines can have an extended service life through upgrades or modifications that enhance performance, functionality, or compatibility with new technology.

What are the safety precautions that need to be maintained when using an industrial CNC router?

When operating an industrial CNC router, following safety protocols can help prevent accidents and ensure a safe work environment. The following are basic safety precautions:

- Training And Knowledge: Ensure operators are fully trained in the operation of the CNC router and understand its components, safety features, emergency procedures, and safe operating practices.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, hearing protection, and, if necessary, a dust mask. Depending on the materials being processed, additional personal protective equipment such as gloves and aprons may be required.

- Machine Inspection: Regularly inspect the CNC router for signs of wear, damage, or malfunction. Make sure all safety features such as emergency stop buttons and interlocks are functioning properly before operating.

- Material Securing: Properly secure the material being processed to prevent movement or displacement during the cutting operation, thereby reducing the risk of accidents due to material movement.

- Machine Area Security: Establish a designated security area around the CNC router. Ensure that only authorized personnel are present in the nearby work area during operations to prevent accidents.

- Tool Inspection And Replacement: Check cutting tools regularly for damage or wear. Follow proper tool changing procedures, making sure to turn off power to the machine and isolate all energy sources during tool changes.

- Dust Collection: Implement an effective dust collection system to minimize airborne particles. May cause respiratory hazards if not handled properly. Maintain and clean dust collection systems regularly.

- Machine Inspection And Maintenance: Perform daily inspections and maintenance checks on the CNC router. Address any problems promptly and follow the manufacturer’s regular maintenance guidelines.

- Fire Safety: Implement fire safety measures and have appropriate fire-fighting equipment available to respond to emergencies, especially when working with combustible materials.

- Electrical Safety: Make sure the CNC router is properly grounded. Keep electrical components in good condition and avoid using damaged power cords or connections.

- Material Compatibility: Confirm that the selected cutting tools and machining parameters are appropriate for the specific material being machined. Incompatible tools or settings may cause security risks.

- Programming And Setup: Carefully review CNC programs and setup parameters to prevent collisions, tool path errors, or unexpected movements that could endanger operator or machine safety.

- Operator Supervision: Always have a qualified operator present during CNC router operation to avoid unattended operation of the machine.

- Follow Manufacturer’s Guidelines: Follow the manufacturer’s guidelines and recommendations as outlined in your machine manual. This includes safety instructions, maintenance schedules, and operating procedures.

- Ongoing Review And Training: Safety procedures are regularly reviewed and ongoing training is provided to operators to stay informed on best practices and safety measures.