Handicraft Industry

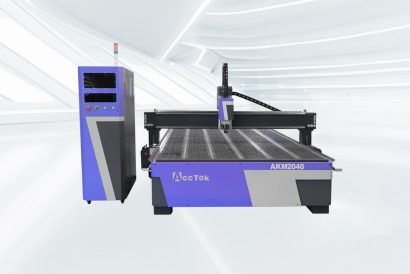

Application of CNC Router in The Handicraft Industry

CNC router enhances handicraft production technology

Joinery And Architectural Precision

For craftsmen involved in building wooden or composite structures, CNC routers offer precise joinery solutions. This technology ensures components fit together seamlessly, enhancing the overall structural integrity and aesthetics of the final product.

Efficient Mass Production

CNC router supports mass production in the handicraft industry, allowing craftsmen to consistently produce the same designs and patterns. The CNC router ensures that every copy is identical, eliminating the differences that can arise with manual production methods.

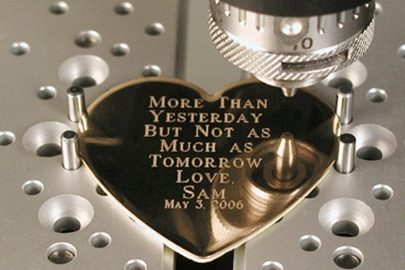

Accuracy And Precision

CNC routers excel at delivering unparalleled precision. Whether cutting intricate designs or engraving detailed patterns, these machines ensure consistent and precise results, improving the quality of the final product.

Speed And Efficiency

CNC router helps improve time and labor efficiency in the production process. It helps reduce manual labor, minimizes material waste, and increases overall production speed, allowing craftsmen to focus on the creative aspects of their craft.

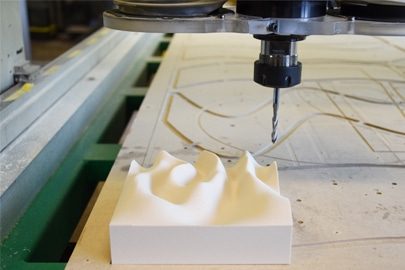

Material Diversity

CNC routers work with a variety of materials such as wood, plastic, metal, foam, and even certain types of stone. This versatility expands the range of materials available to craftsmen, opening up new avenues for creativity and innovation.

Mixed Media Innovation

CNC router allows craftsmen to explore innovative combinations of materials in handicrafts. Combining wood with metal or plastic can produce unique and visually striking creations, while CNC technology facilitates the precise integration of these materials.

Complex Design Implementation

In an industry where complex designs are indispensable, CNC routers enable craftsmen to easily turn these designs into reality. This technology helps produce detailed and refined pieces that may be impractical or nearly impossible to achieve manually.

Prototyping And Customization

CNC router simplifies the process of handicraft prototyping and customization. Craftsmen can quickly produce prototypes to test new designs or efficiently fulfill custom orders. The technology can provide greater flexibility and responsiveness to customer preferences.