Rotary Axis CNC Router

The rotary axis CNC router is a processing tool specially designed for 3D carving and engraving on cylindrical or curved surfaces. Unlike 3-axis CNC routers, rotary-axis CNC routers add a fourth axis of rotation (A-axis) to accommodate round or cylindrical workpieces. This allows complex designs to be machined on objects such as cylindrical wood pieces, table legs, baseball bats, or sculptures.

A-axis rotation enables the CNC router to operate around the circumference of the workpiece, providing multi-sided access for precise and detailed engraving. By synchronizing motion across multiple axes, complex designs, and patterns can be created with high precision and efficiency. The rotary axis CNC router is suitable for a variety of industries including woodworking, prototyping, aerospace, and automotive that require complex curved or cylindrical parts. It offers versatile design capabilities, allowing craftsmen and manufacturers to produce unique and intricate pieces with precision.

Tips For Choosing The Right Rotary Axis CNC router

Start your journey to choose a rotary-axis CNC router. From compatibility and accuracy to budget considerations, we provide expert insights to help you make informed decisions. Whether it’s a complex design or an industrial need, let us uncover the tips for selecting the best machine to move your project forward.

Rotary Axis Compatibility

Make sure the CNC router you choose is specifically designed to support rotary axis functionality. Check that it has the necessary hardware and software capabilities to integrate smoothly with the rotating attachment. Verify that the system can accurately control and synchronize the rotational motion required for your intended application.

Workpiece Size And Capacity

Evaluate the maximum workpiece diameter and length that the CNC router can accommodate. Consider your specific project requirements and make sure the CNC router’s capacity is consistent with the dimensions of the cylindrical or curved objects you plan to machine. Choosing a CNC router with an adequate working range helps achieve versatility and flexibility in your project.

Precision And Accuracy

Check the CNC router’s specifications related to rotational accuracy and overall accuracy. Evaluate the machine’s accuracy in handling complex designs on curved surfaces. Consider factors such as gap compensation, rigidity, and repeatability to ensure precision machining.

Drive Mechanism, Construction, And Durability

Evaluate the drive mechanism used by the CNC router, such as whether a stepper motor or servo motor is used. Consider the overall structure and materials used in its manufacture to ensure sturdiness and durability. A well-built machine with quality components is more likely to provide reliable performance and withstand long-term use.

Ease of Use And Software Compatibility

Evaluate the user-friendliness of the CNC router interface and controls. Intuitive controls and a user-friendly interface facilitate efficient operation. Additionally, check compatibility with commonly used design software. Seamless integration with your preferred CAD/CAM software streamlines workflow and increases productivity.

Tool Options, Speeds, And Feeds

Research the availability of tool options and accessories compatible with your CNC router. Different projects may require specific tools for best results. Check the CNC router’s speed and feed rate capabilities to ensure they meet your production requirements without sacrificing the quality of the machined surface.

Budget And Return on Investment (ROI)

Consider your budget constraints and evaluate the capabilities of your CNC router versus return on investment. While it’s important to stay within your budget, also evaluate the long-term benefits a CNC router can provide to your business. The balance between initial costs and future benefits helps achieve a sound investment.

Support And Service

Research the manufacturer or supplier’s reputation for customer support and service. A reliable support system helps resolve any technical issues or queries promptly. Check warranty, spare parts availability, and support team responsiveness to ensure continued reliability.

Comments And Suggestions

Find reviews, recommendations, and advice from users in similar industries. Real-world experience provides valuable insights into CNC router performance, reliability, and user satisfaction. Look for feedback patterns to gauge the machine’s overall reputation in the market.

What Materials Can The Rotary Axis CNC Router Cut?

The materials that a rotary axis CNC router can cut depend on the CNC router’s specifications, tool, and cutting parameters, so the CNC router’s capabilities and limitations for each material type must be considered.

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Aluminum

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

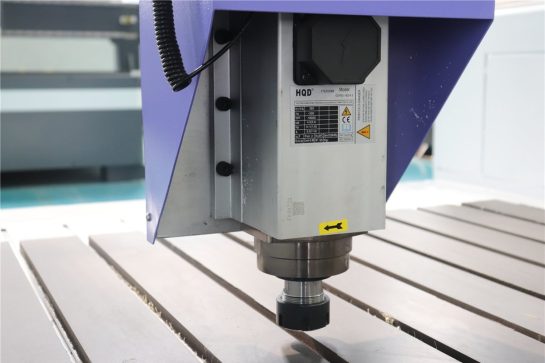

The Impact of Spindle Power on CNC Router Functionality

This article will delve into how spindle power affects the overall functionality of CNC routers, helping users make informed decisions based on their specific production needs.

Read More

How to Evaluate Energy Consumption and Operating Costs of CNC Router?

This article will guide you through the elements to consider when evaluating the energy consumption and operating costs of a CNC router, providing you with strategies to reduce operating costs.

Read More

How do I Choose The Right CNC Router Size and Capacity for a Specific Need?

In this article, we’ll walk you through the key considerations when determining the proper size and capacity of a CNC router, aiming to help you make an informed decision that ...

Read More

How to Choose the Perfect Woodworking CNC Router Bit

In this article, we’ll walk you through the essential factors to consider when choosing the perfect woodworking CNC router bit. We aim to help you choose the best router bit ...

Read More

Building Musical Instrument with CNC Router: A Comprehensive Guide

This article explores the role of CNC routers in musical instrument manufacturing, providing you with the basic knowledge and guidance you need to use a CNC router to manufacture musical ...

Read More

What Should I Know Before Buying a CNC Router?

This article discusses the things you need to know before buying a CNC router from multiple aspects, aiming to help you choose a machine that can improve your productivity and ...

Read More

Frequently Asked Questions

What is the rotary axis on a CNC router?

The rotary axis on the CNC router is an additional axis, usually labeled “A-axis”, that enables the rotation of the workpiece. Traditional 3-axis CNC routers operate on three axes (X, Y, and Z) to move along a linear path, while the rotary axis adds a fourth rotational dimension.

The rotary axis allows the CNC router to work on cylindrical or curved surfaces. Rather than just moving the cutting tool in a linear direction, the A-axis enables the CNC router to rotate the workpiece, allowing it to engrave or engrave on the circumference of a cylindrical object. This feature is particularly useful for tasks such as machining table legs, rotating parts, or complex designs on sculptures.

By integrating a rotary axis, the CNC router gains versatility, allowing it to handle a wider range of projects involving round or cylindrical workpieces. This feature is especially beneficial for industries such as woodworking, prototyping, and manufacturing, where the ability to work on curved surfaces is critical.

How do you choose the installation position of the CNC rotary axis?

Choosing the installation location of the CNC router’s rotary axis, whether on the side of the machine or the work table, requires careful consideration of various factors. Here’s a breakdown of the considerations for both options:

The rotary axis on one side

- Advantage:

- Mounting the rotary axis on the side saves bench space, allowing for larger workpieces or multiple setups simultaneously.

- Because the rotating axis does not obstruct the workbench, workpieces can be loaded and unloaded more easily, improving operator convenience.

- Shortcoming:

- Additional floor space is required on one side of the machine.

- Since the rotary axis has a fixed position, the overall length of the workpiece may be limited.

- Advantage:

- Maximize the use of existing machine floor space.

- The axis of rotation can be flexibly positioned along the length of the table.

- Allows longer workpieces to be machined by repositioning the rotary axis.

- Shortcoming:

- Material handling may be complicated, especially with heavy or bulky workpieces.

- Careful planning is required to avoid interference with linear axes and tools.

- Workpiece Length: If you often handle long workpieces or workpieces of different lengths, mounting the rotary axis on the workbench allows flexibility to accommodate different sizes.

- Space Constraints: Evaluate the available floor space of your workshop. If space is limited, mounting the rotary axis on the workbench may make more efficient use of the existing floor space.

- Workflow Efficiency: Consider the overall workflow and how mounting location affects material handling, tool changes, and overall machining efficiency.

- Operator Accessibility: Evaluate how each option affects operator access to the appliance, especially during setup, programming, and maintenance.

- Interference And Collisions: Ensure that the chosen mounting location avoids interference with other machine components, linear axes, and tools.

- Material Handling: Evaluate the ease or difficulty of loading and unloading materials based on the selected installation location.

- Future Upgrades: Consider the possibility of future upgrades or changes in processing needs. Choose a mounting location that allows for adaptability and future modifications.

How does a rotary-axis CNC router work?

Rotary axis CNC routers work by combining a fourth axis of rotation (often labeled the “A-axis”) with the traditional three linear axes (X, Y, and Z). This additional axis enables the CNC router to handle cylindrical or curved workpieces with rotational motion. Here are step-by-step instructions on how to operate a rotary axis CNC router:

- Design And Programming: Use computer-aided design (CAD) software to create a 3D design of the object to be machined. The design should consider the rotation capability of the rotation axis.

- CAM Programming: Use computer-aided manufacturing (CAM) software to convert 3D designs into machine-readable code. The CAM program takes into account the rotational motion required by the rotating axis to generate the tool path.

- Material Setup: Secure the workpiece in the CNC router’s work area, ensuring proper alignment and fixation. The axis of rotation can accommodate cylindrical or curved materials such as wood dowels, pipes, or other round objects.

- Origin Positioning: Move the cutting tool (spindle) of the CNC router to the starting position (origin position) according to the programmed linear axis and rotation axis coordinates.

- Tool Changes (If Necessary): If various aspects of the machining process require different tools, the CNC router can perform automatic tool changes to meet design requirements.

- Machining Process: The CNC router executes the programmed tool path while moving on the linear axes (X, Y, Z) and rotating around the A-axis as needed. This coordinated motion enables the cutting tool to carve, carve or shape the workpiece in three dimensions.

- Rotary Motion: The A-axis rotates the workpiece, allowing the CNC router to process different sides or angles. This rotational motion is synchronized with linear motion, allowing complex and detailed machining on curved or cylindrical surfaces.

- Finishing And Finishing: As the CNC router follows the programmed tool path, it completes the machining process, producing the desired design on the workpiece.

- Tool Retraction And Workpiece Removal: After processing is completed, the tool is retracted and the completed workpiece can be safely removed from the CNC router.

- Cleaning And Maintenance: Clean the CNC router and perform any necessary maintenance tasks to ensure its continued accuracy and reliability.

What can a rotary-axis CNC router machine do?

The rotary-axis CNC router can perform a variety of machining operations on cylindrical or curved workpieces, adding versatility to traditional CNC routing capabilities. Here are some of the applications and tasks that a rotary-axis CNC router can handle:

- 3D Carving and Engraving: Create intricate 3D carvings and engravings on cylindrical objects, such as decorative columns, table legs, or artistic sculptures.

- Rotary Sign Making: Produce curved or cylindrical signs with detailed lettering and graphics for applications like outdoor signage, displays, or branding.

- Woodturning And Lathe Work: Simulate woodturning and lathe work by carving patterns, grooves, or intricate details on turned wooden pieces like chair legs, balusters, or spindles.

- Cylindrical Parts Production: Machine cylindrical parts with precision, are ideal for industries such as aerospace, automotive, or manufacturing where components have curved or rounded features.

- Rotary Indexing: Use the rotary axis for indexing operations, allowing the CNC router to work on multiple sides of a cylindrical workpiece without repositioning it manually.

- Rotary Fluting And Twisting: Create fluted or twisted patterns on cylindrical surfaces, adding decorative elements to furniture components or architectural details.

- Rotary Nesting: Efficiently nest and cut multiple parts on cylindrical stock, optimizing material usage and minimizing waste.

- Custom Woodworking: Execute customized woodworking projects that involve curved or cylindrical elements, providing a solution for unique and artistic designs.

- Artistic And Decorative Items: Produce artistic or decorative items with intricate patterns, textures, or reliefs on curved surfaces, expanding creative possibilities for artisans and designers.

- CNC Lathe Operations: Simulate lathe operations on a CNC router by utilizing the rotary axis, allowing for the production of turned components without the need for a dedicated lathe machine.

- Multi-Axis Machining: Combine the rotary axis with other linear axes for multi-axis machining, enabling the creation of complex geometries and highly detailed components.

Why choose the rotary axis CNC router?

Choosing a rotary axis CNC router offers several advantages that make it the first choice for certain applications and industries:

- Processing Versatility: The rotary axis adds a fourth axis (A-axis) to the traditional X, Y, and Z axes, which can process cylindrical or curved surfaces. This versatility enables the creation of complex designs on a variety of objects.

- Intricate Designs on Cylindrical Objects: Ideal for engraving, engraving or machine detailed designs on cylindrical objects such as table legs, columns or turned wooden parts. These designs can be challenging for traditional CNC routers.

- Improved Efficiency: Rotary axes facilitate multi-sided machining of cylindrical workpieces in one setup, reducing the need for repositioning and increasing overall machining efficiency.

- Reduced Material Handling: Streamline machining of curved or cylindrical parts, minimizing the need to manually reposition workpieces. This saves time and increases productivity.

- Reduce Material Waste: Allows for optimized cutting paths on curved surfaces, minimizing material waste and maximizing raw material utilization.

- Art And Decorative Applications: Suitable for art and decorative applications, allowing the creation of sculptures, ornaments and custom designs with intricate details on round surfaces.

- Custom Woodworking: The ability to produce custom woodworking projects such as furniture, stair railings, and decorative elements with curved or turned features.

- Rotary Engraving: Ideal for performing rotary engraving tasks on items such as pens, bottles or trophies, allowing logos, text or designs to be applied to curved surfaces.

- Prototyping And Modeling: Beneficial for prototyping and modeling in industries that require curved or rounded features, such as product design or manufacturing.

- Professional Applications: For industries requiring specialized tools or fixtures with curved parts, providing a versatile solution for manufacturing complex parts.

- Precision And Repeatability: The CNC control system ensures precise and repeatable motion for consistent and accurate machining results on curved surfaces.

- Wide Range of Materials: The ability to process a variety of materials, including wood, plastics, composites, stone, etc., expands its applicability in different industries.

- Enhanced Design Possibilities: Unlock new design possibilities by creating complex shapes and patterns on round or cylindrical surfaces.

How much does a rotary-axis CNC router cost?

Different specifications will result in different rotary axis CNC router prices, which is why our sales staff needs to understand your processing needs first. They can provide you with suitable machine specifications and quotes based on your specific processing needs. Generally speaking, the price of a rotary axis CNC router ranges from $3,500 to $25,000.

Generally speaking, a rotary-axis CNC router with a large worktable and a high-power spindle is more expensive than a rotary-axis CNC router with a small worktable and a low-power spindle. In addition, other configurations (such as ATC spindle, vacuum table, automatic lubrication, etc.) will also affect the price of the rotary axis CNC router.

When selecting a rotary axis CNC router, you must consider your specific machining needs, the size of the workpiece you plan to machine, and the level of accuracy you require. Also consider costs such as software, tools, training, and any necessary accessories or upgrades. If you want to know the price and specifications of any rotary axis CNC router, please feel free to contact us.

How to lubricate the rotary axis CNC router?

Proper lubrication helps maintain the performance and service life of your rotary axis CNC router. Here are general guidelines on how to lubricate rotating shafts:

- Refer to Manufacturer’s Guide: Always refer to the manufacturer’s manual or guide for specific lubrication requirements and recommendations. Different machines may have different lubrication needs.

- Identify Lubrication Points: Find designated lubrication points on the rotary axis. These points typically include bearings, sliders, gears, and other moving parts.

- Use The Right Lubricant: Choose the appropriate lubricant recommended by the manufacturer. Typically, use a lightweight oil or grease appropriate for the machine components. Avoid using lubricants that may attract dirt or debris.

- Clean Components: Before applying new lubricant, make sure components are clean and free of dirt or debris. Wipe the surface with a clean cloth or use a suitable cleaner as needed.

- Apply Lubricant: Use a grease gun or applicator to apply lubricant to designated spots. Apply lubricant sparingly, as overlubrication can attract dirt and debris, causing potential problems.

- Manually Rotate The Axis: After applying lubricant, manually rotate the axis to ensure that the lubricant is evenly distributed on the moving parts. This aids in proper diffusion of lubricant and ensures smooth operation.

- Periodic Lnspections: Establish a periodic maintenance schedule to inspect and lubricate rotary axis. The frequency of lubrication depends on factors such as machine usage, operating conditions and the type of lubricant used.

- Wipe Off Excess Lubricant: After operation, wipe off any excess lubricant that may have accumulated on the surface. Too much lubricant can attract dirt or debris, causing potential problems.

- Monitor And Reapply As Necessary: Monitor the condition of lubricated parts regularly. Reapply lubricant as necessary, especially if there are signs of dryness or increased friction.

- Consider An Automatic Lubrication System: Some CNC routers are equipped with automatic lubrication systems that apply the required amount of lubricant regularly. If available, ensure that such systems are functioning properly.

- Maintenance Records: Keep records of lubrication schedules and maintenance activities performed on rotating shafts. This helps track maintenance history and ensure timely repairs.

- Consult The Manufacturer: If you have questions or encounter specific problems, consult your CNC router manufacturer or dealer for guidance. They can provide tailored advice based on the model and specification of your machine.

What CNC router software and control system can a rotary axis CNC router use?

The rotary-axis CNC router can use various CNC router software and control systems that support the integration of a fourth rotary axis (A-axis) for machining curved or cylindrical surfaces. Here are some commonly used software and control systems compatible with rotary-axis CNC routers:

CAD/CAM Software

- CAD/CAM software like AutoCAD, SolidWorks, Fusion 360, RhinoCAM, Vectric Aspire, or Mastercam can generate tool paths and designs that incorporate rotational movements for rotary-axis machining.

- Mach3 or Mach4: Popular control software allowing integration with rotary axes.

- Siemens SINUMERIK: Offers solutions for multi-axis machining and can be adapted for rotary-axis CNC routers.

- Fanuc CNC: Supports multi-axis control, allowing integration of rotary axes.

- Haas CNC: Provides control systems compatible with rotary-axis configurations.

- Centroid CNC: Offers control systems suitable for rotary-axis CNC applications.

- NUM CNC: Provides solutions for simultaneous multi-axis machining, including rotary axes.

- CAM software is explicitly designed to support rotary-axis CNC routing, providing functionalities for creating and simulating tool paths for curved or cylindrical machining.

- Some software may offer specialized add-ons or plugins specifically tailored for rotary-axis functionality. These add-ons enhance the software’s capabilities for programming and controlling the rotary axis.