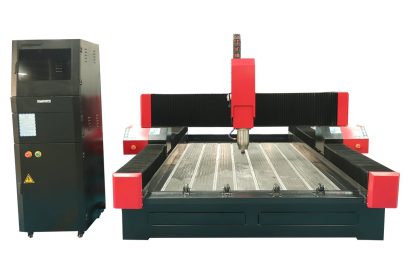

Stone

Types of Stone That CNC Router Can Process

- Marble

- Granite

- Limestone

- Travertine

- Sandstone

- Slate

- Basalt

- Quartzite

- Quartzite

- Onyx

- Soapstone

- Talc

Operations That CNC Routers Can Perform on Stone

Engraving And Carving

CNC routers excel at detailed engraving and carving on stone surfaces, allowing for the creation of intricate patterns, textures, and reliefs. Whether it's a delicate floral design or a bold inscription, the router's precision ensures accurate reproduction.

Cutting And Shaping

Stone pieces of various shapes and sizes can be precisely cut and shaped using CNC routers. This includes cutting out precise geometrical shapes, curves, and contours, enabling the production of custom pieces with minimal material wastage.

Routing And Profiling

CNC routers are adept at routing and profiling tasks, allowing for the creation of smooth edges, intricate profiles, and complex contours on stone surfaces. This is particularly valuable in producing decorative elements for architectural applications.

Surface Finishing

CNC routers can be employed to achieve different surface finishes on stone, ranging from polished to textured. This capability enhances the aesthetic appeal of stone products and provides a tailored finish to meet specific design requirements.

Drilling And Milling

Precision drilling and milling operations are essential in stone applications, especially in the creation of holes for fixtures or in the production of three-dimensional stone components. CNC routers ensure accuracy in these processes, reducing manual labor and increasing efficiency.

Inlay Work

CNC routers can be used to cut precise recesses in stone, allowing for inlay work with various materials such as metals or other stones. This technique adds a layer of complexity and elegance to the finished product.

Lettering And Inscriptions

Creating finely detailed letters and inscriptions on stone surfaces is a common application for CNC routers. The precision of these machines ensures that text is accurately reproduced, whether it's for memorial stones, plaques, or decorative signage.

Prototyping And Customization

Stone artisans and designers can use CNC routers for prototyping and experimenting with custom designs. This capability enables a high degree of customization, allowing for the creation of unique and personalized stone products.