Jewelry Industry

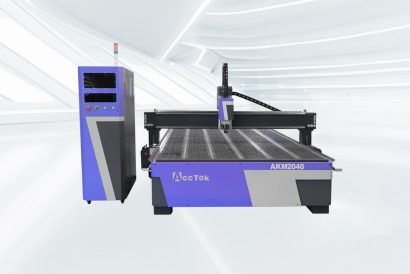

Application of CNC Router in The Jewelry Industry

CNC Router Improves Production Technology in The Jewelry Industry

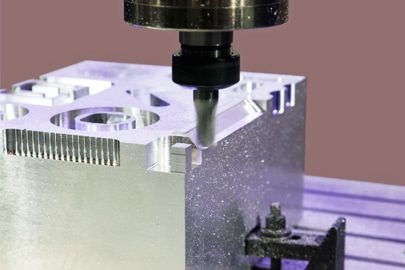

Precision Cutting And Routing

CNC routers specialize in precision cutting and routing of a variety of materials used in jewelry making, such as metals, gemstones, and acrylics. It improves accuracy and consistency in cutting complex shapes and designs, ensuring a high-quality finished product.

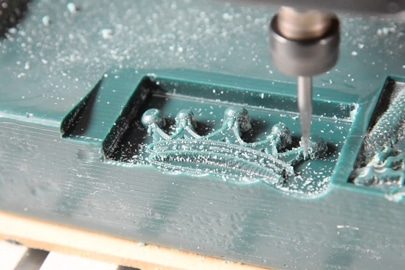

Engraving And Etching

CNC routers excel at precisely engraving and etching intricate designs on a variety of jewelry surfaces. Whether adding personalized inscriptions, intricate patterns, or textures, the CNC router ensures a level of detail that would be difficult to achieve by hand.

Customization And Prototyping

CNC router facilitates the production of custom jewelry and prototyping. It enables jewelers to quickly and accurately produce prototypes of new designs, facilitating a more efficient iterative design process.

Texture And Finish

CNC routers achieve surface finishing by adding texture and pattern to jewelry pieces. This feature enhances the aesthetics of the final product, giving designers the tools to create unique and visually captivating surfaces.

Filigree And Intricate Designs

Many pieces of jewelry feature intricate filigree work and detailed metalwork, and a CNC router can make this easier. It cuts and shapes metal with precision, allowing craftsmen to create delicate and intricate designs.

Mass Customization

Customization has become a major trend in the jewelry industry. CNC routers enable mass customization and meet the demand for unique and personalized jewelry by efficiently producing personalized products without compromising accuracy or quality.

Gemstone Setting

CNC router helps in accurately carving gemstone settings. Whether it's a channel setting, pave setting, or other complex design, it cuts precisely shaped grooves to hold the stone securely, ensuring a seamless and carefully crafted end product.

Casting Wax Pattern

In jewelry manufacturing, wax models are often created as casting prototypes. CNC router can produce high-precision wax models based on digital designs, thereby simplifying the prototyping process. This not only saves time but also ensures consistency and accuracy in the jewelry molds.