Metal CNC Router

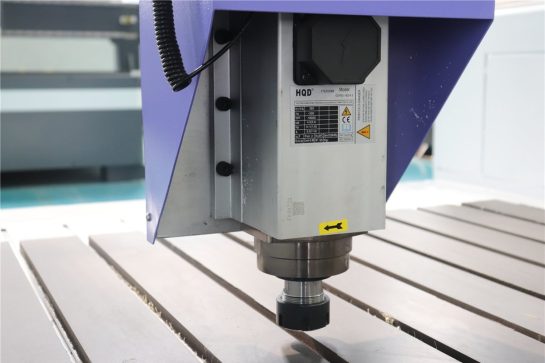

The metal CNC router is a precision machining tool specially used for high-precision cutting and shaping various metal materials. These CNC routers utilize computer numerical control (CNC) technology to automate the machining process to achieve complex metal designs. The CNC router’s cutting head is equipped with specialized metal-cutting tools, such as end router bits, controlled by a computer program that dictates the tool’s movements in three dimensions.

The metal CNC routers are widely used in aerospace, automotive, and manufacturing industries that require complex metal parts. Its ability to produce high-quality, repeatable results makes them indispensable for a wide range of tasks in metal processing, from prototype development to large-scale production. This technology has revolutionized metal processing, providing manufacturers a reliable, efficient solution to create complex metal parts with unparalleled precision.

Tips For Choosing The Right Metal CNC Router

Navigating the world of precision machining requires insight and careful consideration, so let’s dive into the basic considerations, from determining the ideal work area and spindle dimensions to evaluating automatic tool change capabilities. Whether you’re a seasoned professional or new to the world of CNC machining, we’ll guide you through the essential elements that define the perfect CNC companion for your metal fabrication needs.

Working Area Size

Consider the size of the sheet metal or workpiece you typically work with. Choose a metal CNC router with a work area (bed size) that easily meets your project requirements. Make sure the machine is sized for your current and potential future needs.

Automatic Tool Changer

Evaluate whether your project involves multiple tool changes. If your job involves multiple cutting operations using different cutters, consider a CNC router with ATC capabilities. This enables the machine to automatically switch tools, saving time and improving overall efficiency during complex projects.

Spindle Power And Speed

Evaluate the spindle power and speed relative to the metal you plan to cut. Choose a machine with the appropriate spindle power to handle the hardness of the metal you are working with. Also, consider variable speed options for versatility in handling different cutting tasks. Choose the spindle that suits your specific application needs.

Control System And Software

Control systems and software facilitate the programming and operation of CNC routers. Choose a machine with a user-friendly interface and compatible software that matches your skill level and project requirements. Features such as simulation capabilities and easy tool path creation increase efficiency.

Protective Case

Determine if your application requires a semi-enclosed enclosure or a fully enclosed enclosure. The semi-enclosed box provides adequate protection while allowing for easy observation and adjustment. In contrast, a fully enclosed housing prevents chips and debris from escaping, thereby increasing safety and making it suitable for applications with stringent cleanliness requirements.

Rigidity And Build Quality

Evaluate the rigidity and manufacturing quality of CNC routers. Sturdy and well-constructed machines minimize vibrations during cutting operations, ensuring greater precision and surface finish. Check the materials used in the machine’s construction, the overall design, and the machine’s stability under different operating conditions.

What metals can the metal CNC router cut?

The metal CNC router is capable of cutting a variety of metals, offering versatility in metal fabrication. Common metals that can be cut using a metal CNC router include:

- Stainless Steel

- Carbon Steel

- Gold

- Silver

- Aluminum

- Copper

- Platinum

- Brass

- Cast Iron

- High-Speed Steel

- Bronze

- Iron

- Titanium

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

The Impact of Spindle Power on CNC Router Functionality

This article will delve into how spindle power affects the overall functionality of CNC routers, helping users make informed decisions based on their specific production needs.

Read More

How to Evaluate Energy Consumption and Operating Costs of CNC Router?

This article will guide you through the elements to consider when evaluating the energy consumption and operating costs of a CNC router, providing you with strategies to reduce operating costs.

Read More

How do I Choose The Right CNC Router Size and Capacity for a Specific Need?

In this article, we’ll walk you through the key considerations when determining the proper size and capacity of a CNC router, aiming to help you make an informed decision that ...

Read More

How to Choose the Perfect Woodworking CNC Router Bit

In this article, we’ll walk you through the essential factors to consider when choosing the perfect woodworking CNC router bit. We aim to help you choose the best router bit ...

Read More

Building Musical Instrument with CNC Router: A Comprehensive Guide

This article explores the role of CNC routers in musical instrument manufacturing, providing you with the basic knowledge and guidance you need to use a CNC router to manufacture musical ...

Read More

What Should I Know Before Buying a CNC Router?

This article discusses the things you need to know before buying a CNC router from multiple aspects, aiming to help you choose a machine that can improve your productivity and ...

Read More

Frequently Asked Questions

Can you use a CNC router on metal?

Yes, CNC routers can be used for metal processing, and there are CNC routers specifically designed for metal-cutting applications. Although CNC routers are more commonly associated with woodworking and plastics, advances in technology and tools have made it possible to effectively use CNC routers to machine a variety of metals. These metal CNC routers have features and capabilities that address the unique challenges posed by metal materials.

Here are some key considerations for using a CNC router on metal:

- Tools: The metal CNC routers use specialized tools designed specifically for metal processing. These knives are usually made of materials such as carbide, which can withstand the hardness of the metal.

- Spindle power: Metal routing generally requires higher spindle power than woodworking or plastic routing. The metal CNC router is equipped with a spindle specifically designed for routing metal, which can provide enough power to effectively remove material.

- Machine rigidity: Metalworking generates significant forces and vibrations. The CNC routers designed specifically for metal processing need to have a rigid and stable structure to ensure accuracy and prevent excessive tool deflection.

- Coolant system: The metal CNC routers need to have a built-in coolant system to manage the heat generated during the cutting process. Good cooling helps prevent tool wear and maintains cutting efficiency.

- Workpiece clamping: Proper workpiece clamping helps ensure stability and accuracy. The metal CNC routers may use different clamping mechanisms and fixtures to secure metal workpieces.

- Dust and chip management: Metalworking produces more dust and chips than other materials. The metal CNC routers typically employ effective dust and chip management systems to maintain a clean working environment.

Can you drill metal with a CNC router?

Yes, it is possible to drill metal using a CNC router. The CNC routers equipped with the right tools and appropriate parameters can perform drilling operations on a variety of metals. Here are some considerations for using a CNC router to drill metal:

- Tool selection: Choose a drill bit or vertical router bit suitable for metal drilling. Common options include twist drills, center drills, or carbide vertical router bits. Tool selection depends on the specific requirements of the drilling operation and the type of metal being used.

- Speed and feed rate: Adjust spindle speed and feed rate based on the type of metal being drilled and the size of the drill bit. Metals typically require slower speeds and lower feed rates than softer materials to prevent overheating and ensure proper chip evacuation.

- Cooling and lubrication: Metal drilling generates heat, and adequate cooling and lubrication can help prevent tool wear and extend tool life. Coolants or lubricants can be used during the drilling process.

- Toolpath programming: Use proper toolpath programming to ensure accurate hole location and depth. The CNC router can create precise drilling patterns, and the tool paths should be programmed to match the desired hole specifications.

- Workpiece clamping and fixing: Firmly secure metal workpieces to the CNC router to prevent movement during drilling. Proper workpiece clamping ensures accuracy and safety during machining.

- Machine rigidity: Make sure the CNC router is rigid enough to withstand the forces generated when drilling metal. Rigidity helps maintain precision during drilling and prevents excessive vibration.

- Workpiece fixation: Clamp or secure metal workpieces securely to the CNC router to prevent movement or vibration during drilling. Proper workpiece holding helps achieve precise hole positioning.

- Chip removal: Adequate chip removal prevents tool breakage and ensures smooth drilling operations. Appropriate dust and chip management systems should be in place.

What does a CNC router use to cut metal?

The CNC router uses various cutting tools to cut metal. The choice of cutting tool depends on factors such as the type of metal being cut, the specific machining operation, and the desired finish. Common cutting tools for metal CNC routers include:

- End Router Bit: The end router bits are versatile cutting tools with various configurations, including flat, ball-nose, and corner-radius end router bits. They are suitable for a wide range of metal-cutting applications, such as contouring, slotting, and profiling.

- Drill Bit: The drill bit is used for creating holes in metal. They come in different styles, such as twist drills, center drills, and spot drills, and are chosen based on the specific drilling requirements.

- Face Router Bit: The face router bit has cutting edges on the periphery and the face of the tool. They are effective for facing large flat surfaces and removing material quickly.

- Slotting Router Bit: The slotting router bit is designed for cutting slots in metal. They have a straight or helical tooth configuration and are suitable for machining narrow slots.

- Ball Nose Router Bit: The ball nose router bit is a specialized end router bit with rounded tips. They are often used for 3D profiling and contouring, providing a smoother finish on curved surfaces.

- Reamer: The reamer is used for enlarging or finishing existing holes. They produce a more accurate and smoother hole surface.

- T-slot Router Bit: The T-slot router bit is designed for creating T-shaped slots in metal workpieces, commonly used for securing fixtures and work-holding devices.

- Thread Router Bit: The thread router bit is used to create threads in metal, providing precision in thread milling operations.

- Specialized Router Bit: Depending on the application, there are specialized router bits for specific tasks, such as chamfering, engraving, or grooving.

What metals can a CNC router cut?

The CNC router can cut a variety of metals, but specific capabilities may vary based on the machine’s power, rigidity, and the type of tool used. Common metals that can be cut using a CNC router include:

- Aluminum: The CNC router is great for cutting aluminum, which is a softer metal compared to other metals. It is commonly used in applications ranging from signage to aerospace components.

- Steel: The CNC router can cut mild steel and stainless steel. However, cutting speed and capabilities may depend on the power of the machine and the specific steel type.

- Brass: Brass is a copper alloy that can be precisely machined using a CNC router. Known for its corrosion resistance and aesthetic appearance, this metal is often used in decorative elements and precision parts.

- Copper: Copper is another metal that can be effectively cut using a CNC router. Copper has good electrical conductivity and ductility and is often used in electrical applications and decorative elements.

- Bronze: Bronze is another copper alloy that can also be machined using a CNC router. It is used in applications requiring a combination of strength and corrosion resistance.

- Titanium: Cutting titanium is more challenging due to its hardness and may require a specialized CNC router with high power and appropriate tooling. Titanium is commonly used in aerospace and medical applications.

- Other alloys: The CNC router can also cut other metal alloys, depending on their hardness and properties. Common alloys include aluminum alloys, steel alloys, and nickel alloys.

Which metal materials cannot be processed using a CNC router?

Although CNC routers are versatile and capable of processing various materials, there are challenges and limitations when processing certain types of metals. Certain metals are more difficult to machine on a CNC router due to hardness, toughness, or other specific properties. Here are some metals that may present challenges when using a CNC router:

- Hardened steel: CNC routers may have difficulty cutting extremely hardened steel. These metals are often too hard for standard cutting tools and may require specialized equipment with more powerful spindles and rigid structures, such as milling machines or machining centers.

- High-temperature alloys: Metals like Inconel and other high-temperature alloys are known for their hardness and heat resistance. Machining these metals may require specialized equipment and tools designed for high-temperature applications.

- Tool steel: Tool steels, especially those with high hardness, can be challenging to use with CNC routers. The hardness of these materials may exceed the capabilities of standard cutting tools.

- Hard and brittle materials: Some hard and brittle materials, such as certain ceramics or extremely brittle alloys, may not be suitable for processing on a CNC router. The risk of tool breakage and the inability to achieve precise cuts may limit its use.

- Specialty metals: Specialty metals, such as certain rare earth metals or specialty alloys with unique properties, may require special machining techniques beyond the capabilities of a standard CNC router.

- Hard metals with abrasive properties: Metals with abrasive properties, such as those containing hard particles or ceramics, may accelerate tool wear and pose challenges to the CNC router.

- Heavy metals: Extremely dense or heavy metals such as tungsten can present challenges due to the high forces involved in processing. Efficient machining may require specialized machinery with significant power and rigidity.