Commercial CNC Router

Commercial CNC routers are precision cutting and engraving machines widely used in the manufacturing and woodworking industries. It can automatically shape, carve, and cut a variety of materials including wood, plastic, metal, and composites with incredible precision.

Commercial CNC routers provide unparalleled efficiency in large-scale production runs, allowing rapid prototyping and customization while maintaining consistent quality. Its versatility allows it to accommodate complex designs and complex geometries, making it suitable for industries as diverse as furniture manufacturing, cabinetry, aerospace, automotive, and signage.

Commercial CNC routers are equipped with powerful motors, precise cutting tools, and advanced control systems to deliver superior speed and precision, minimize material waste, and optimize production schedules. Its widespread adoption across industries highlights its integral role in modern manufacturing, delivering innovation, efficiency, and precision in the creation of high-quality products.

Tips For Choosing The Right Commercial CNC Router

Choosing the right CNC router can help simplify the manufacturing process. We provide concise and insightful tips that address key considerations from material compatibility to budget constraints. Whether you are a seasoned professional or new to CNC technology, we will guide you through the complex process of selecting the perfect CNC router for your business needs.

Usage And Material Compatibility

Define the main purpose of the CNC router and the materials you intend to use it with. Consider the complexity of your project and whether the machine is suitable for wood, metal, plastic, or composite materials. Make sure the CNC router’s design and specifications meet your specific material compatibility requirements for optimal performance.

Dimensions And Capacities

Evaluate typical workpiece dimensions and expected throughput. Choose a CNC router with a bed size and capacity that can easily accommodate your materials. Consider the physical size of the machine and its work area, and anticipate future growth by choosing a CNC router that can handle larger projects as your business expands.

Accuracy Requirements

Determine the level of accuracy required for your project. Evaluate the accuracy, repeatability, and resolution capabilities of CNC routers. Consider the type of work you do and whether the machine can consistently meet the required tolerances.

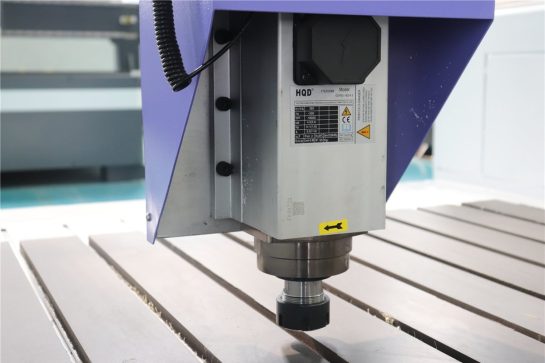

Spindle Power And Speed

Analyze your spindle’s power and speed options based on the material you plan to cut. Different materials and cutting applications may require specific spindle capabilities. Choose a CNC router with a spindle that provides the power you need to cut efficiently and at the right speed for clean, accurate results.

Control System

Evaluate the control system’s interface and its compatibility with your preferred CAD/CAM software. A User-friendly interface improves work efficiency. Make sure the control system supports your team’s proficiency level and provides the functionality required for the project.

Tool Changing Ability

Evaluate the CNC router’s tool-changing capabilities, especially if your project involves multiple tools or tool changes. An automatic tool changer simplifies production by enabling the machine to switch tools seamlessly. Consider the capacity of the tool changer, the speed of tool changes, and the system’s ability to adapt to different tool types and sizes.

Easy To Use And Train

Consider the overall user-friendliness of the CNC router. A well-designed interface and intuitive controls can significantly impact productivity. Evaluate the availability of training resources and support from the manufacturer to ensure your team can adapt quickly and maximize the capabilities of your CNC router.

Maintenance And Support

Evaluate ease of maintenance and availability of technical support. Choose a CNC router with durable and easy-to-use components to simplify routine maintenance. Research the manufacturer’s reputation for customer support to ensure timely help and spare parts are available when needed.

Budget Considerations

Establish a comprehensive budget that includes not only the initial purchase cost but also additional costs such as software, tools, and maintenance. Consider factors such as efficiency, accuracy, and durability, and balance budget constraints with the long-term value of your CNC router.

Comments And Suggestions

Research customer reviews and seek recommendations from businesses in your industry. Learn from other people’s experiences using a specific CNC router make or model. Consider feedback on reliability, performance, and any challenges faced during operation to make an informed decision.

Warranty And After-Sales Service

Check the warranty terms provided by the manufacturer. A solid warranty shows confidence in the quality of the product. Also, ask about after-sales service and support to ensure you can get help if something goes wrong or you need an upgrade.

Future Expansions And Upgrades

Anticipate potential future business growth and evaluate the scalability of CNC routers. Choose a machine that is easily expandable and upgradeable and can adapt to changes in production needs and technological advancements without having to replace the entire system. Consider upgrade options, availability of software updates, and compatibility with emerging technologies.

What Materials Can A Commercial CNC Router Cut?

The commercial CNC router is a versatile tool capable of cutting a wide range of materials. The specific capabilities may vary depending on the machine’s design and specifications, but commonly, commercial CNC routers can cut materials such as:

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

The Impact of Spindle Power on CNC Router Functionality

This article will delve into how spindle power affects the overall functionality of CNC routers, helping users make informed decisions based on their specific production needs.

Read More

How to Evaluate Energy Consumption and Operating Costs of CNC Router?

This article will guide you through the elements to consider when evaluating the energy consumption and operating costs of a CNC router, providing you with strategies to reduce operating costs.

Read More

How do I Choose The Right CNC Router Size and Capacity for a Specific Need?

In this article, we’ll walk you through the key considerations when determining the proper size and capacity of a CNC router, aiming to help you make an informed decision that ...

Read More

How to Choose the Perfect Woodworking CNC Router Bit

In this article, we’ll walk you through the essential factors to consider when choosing the perfect woodworking CNC router bit. We aim to help you choose the best router bit ...

Read More

Building Musical Instrument with CNC Router: A Comprehensive Guide

This article explores the role of CNC routers in musical instrument manufacturing, providing you with the basic knowledge and guidance you need to use a CNC router to manufacture musical ...

Read More

What Should I Know Before Buying a CNC Router?

This article discusses the things you need to know before buying a CNC router from multiple aspects, aiming to help you choose a machine that can improve your productivity and ...

Read More

Frequently Asked Questions

What is a commercial CNC router?

The commercial CNC router is a complex computer-controlled machine used in manufacturing and manufacturing processes. It operates by interpreting digital designs or software instructions and converting them into precise movements of a cutting tool or drill bit on a variety of materials. Unlike manual operations, CNC router automates the production process, improving accuracy, speed, and repeatability.

Designed for commercial applications, these CNC routers come in a variety of sizes and configurations to accommodate different workpiece sizes and material types. It is good at cutting, engraving, milling, and carving operations on materials such as wood, plastic, metal, composites, and more. Equipped with powerful motors, precise cutting tools, and advanced control systems, commercial CNC routers play a key role in industries such as woodworking, cabinetry, aerospace, automotive, signage, and prototyping, delivering unparalleled efficiency in modern manufacturing processes, precision, and versatility.

How do commercial CNC routers make money?

Using a commercial CNC router can be a lucrative investment for various industries. Here are the details on how to generate income with your CNC router:

- Custom Furniture And Woodworking: Create custom furniture, intricate wood carvings, and professional woodworking projects. Enter the market of personalized, high-quality wood products to meet the preferences of specific customers.

- Signage & Lettering: Create custom signage and lettering for your business, event, or individual. CNC routers can precisely cut and engrave materials such as acrylic, wood, and metal to create eye-catching signage.

- Prototyping And Product Development: Prototyping services for inventors, designers, and businesses seeking to develop new products. CNC routers excel at creating precise prototypes that help refine and test concepts before full-scale production.

- Art and Decorative Objects: Explore art applications by creating unique works of art, wall decorations, or intricate carvings. Sell these items through art galleries, online platforms, or directly to customers who appreciate custom décor.

- Bespoke Cabinetry And Joinery: Specializing in bespoke cabinetry, door, and joinery solutions for residential or commercial clients. CNC router improves the accuracy and efficiency of creating complex designs.

- Contract Manufacturing: Engage in contract manufacturing by providing CNC cutting and machining services to other businesses. This may involve producing specific components or parts to customer specifications.

- Retailer Mass Production: Cooperate with retailers or e-commerce platforms to mass-produce certain products. This can include items such as home décor, furniture components, or specialty merchandise.

- Educational Seminars: Provide seminars or training courses on CNC technology and its applications. Share your expertise with individuals or businesses who want to learn how to operate a CNC router for projects.

- Architectural Models: Work with architects and designers to produce detailed architectural models and prototypes. CNC routers can bring precision and accuracy to construction projects.

What is the cost of a commercial CNC router?

The cost of commercial CNC routers varies widely based on a variety of factors, including size, features, brand, and additional features. Entry-level CNC routers designed for small workshops or hobbyists start at about $3,000 to $8,000. These machines typically have smaller work areas and fewer advanced features.

Mid-range commercial CNC routers offer larger work areas, higher precision, and more powerful features, with prices ranging from $50,000 to $30,000. These machines are suitable for small and medium-sized businesses that require higher production capacity and versatility.

High-end commercial CNC routers with extensive functionality, larger bed sizes, advanced tooling, high precision and automation range in price from $15,000 to $100,000. These machines cater to the needs of large-scale manufacturing operations, aerospace, automotive and other industries that require top-notch precision and efficiency.

Customization, additional accessories, software, tools and after-sales service also affect the total cost. Maintenance, training, and software updates are ongoing expenses to consider. The cost of a commercial CNC router should be viewed as an investment in productivity, efficiency, and precision. When determining the most appropriate CNC router within your budget, it is important to evaluate the specific needs of your business, consider long-term benefits, and evaluate the return on investment (ROI) of the machine.

What is the expected lifespan of the commercial CNC router?

The expected service life of a commercial CNC router may vary based on a variety of factors, including its build quality, intensity of use, maintenance, technological advancements, and upgrades. Generally speaking, with proper care and maintenance, a well-maintained commercial CNC router can last 10 to 20 years, and in some cases even longer. The following are key factors that affect lifespan:

- Build Quality: CNC routers built with durable materials and high-quality components tend to have a longer lifespan.

- Use And Maintenance: Regular maintenance, proper cleaning, lubrication, and timely repairs can significantly extend the life of your router. A CNC router that is used heavily without proper maintenance may have its service life shortened.

- Usage Pattern: Frequent and continuous use will affect the service life of the CNC router. Machines tend to last longer when used within recommended operating limits and given appropriate rest intervals.

- Technological Advances: Rapid advancements in technology can make older machines obsolete faster. Upgrading or retrofitting certain components can help extend the usability of CNC routers in the face of technological changes.

- Manufacturer Reputation: The reputation of the manufacturer is important. Machines from reputable manufacturers typically undergo strict quality control processes, resulting in more reliable and durable equipment.

- Environmental Conditions: Operating conditions such as temperature, humidity, and cleanliness of the working environment will affect the service life of the CNC router. Proper environmental control can help reduce wear and tear.

- User Training: Adequate training of machine operators can prevent errors and reduce unnecessary stress on equipment, thus having a positive impact on its service life.

- Manufacturer Support And Spare Parts: The availability of manufacturer support, spare parts, and technical assistance may affect the uptime of a CNC router. Older models may face challenges in obtaining the necessary parts.

- Upgradeability: The ability to upgrade or retrofit certain components can extend the life of a CNC router by incorporating new technology or features without having to replace the entire machine.

How to maintain a commercial CNC router?

Maintaining a commercial CNC router is crucial for optimal performance, prolonged lifespan, and consistent production quality. Here’s a comprehensive guide on how to maintain a CNC router:

- Regular Cleaning

- Keep the machine clean by removing dust, debris, and chips regularly.

- Use compressed air, brushes, and vacuum systems to clean the cutting area, spindle, and other components.

- Lubrication

- Lubricate moving parts, such as linear guides, ball screws, and bearings, according to the manufacturer’s recommendations.

- Ensure proper lubrication intervals and use recommended lubricants.

- Check Belts And Chains

- Regularly inspect belts and chains for wear and tension.

- Replace any worn or damaged belts and adjust tension as needed.

- Inspect Tool Holders And Collets

- Check tool holders and collets for wear or damage.

- Clean and replace them regularly to maintain proper tool alignment and secure tool holding.

- Spindle Maintenance

- Follow the manufacturer’s guidelines for spindle maintenance.

- Monitor spindle runout and replace bearings when necessary.

- Check Wiring And Connections

- Inspect electrical wiring and connections for any signs of wear, damage, or loose connections.

- Ensure proper grounding to prevent electrical issues.

- Calibration

- Regularly calibrate the machine to maintain accuracy.

- Check and adjust the machine’s alignment, ensuring precise movements.

- Software Updates

- Keep CNC control software up to date with the latest versions and patches.

- Update drivers and firmware according to the manufacturer’s recommendations.

- Cooling System

- If applicable, maintain the coolant system by checking fluid levels and ensuring proper flow.

- Clean or replace filters in the coolant system as needed.

- Tool Inspection

- Regularly inspect cutting tools for wear and sharpness.

- Replace tools that show signs of damage or reduced cutting efficiency.

- Backup Parameters And Settings

- Periodically back up machine parameters and settings to prevent loss of critical data.

- Store backups securely for quick recovery in case of a system failure.

- Emergency Stop Testing

- Regularly test and ensure the functionality of emergency stop buttons and safety features.

- Training And Documentation

- Provide ongoing training for operators on proper machine use and maintenance.

- Keep detailed records of maintenance activities, repairs, and any issues encountered.

- Professional Servicing

- Schedule routine professional servicing and inspections by the manufacturer or a qualified technician.

- Address any identified issues promptly to prevent further damage.