1530 CNC Router

The 1530 CNC router is a versatile, high-performance machine designed to meet the diverse needs of professionals and hobbyists in industries like woodworking, signage, cabinetry, and metalworking. Renowned for its precision and durability, this router features a spacious 1500mm x 3000mm worktable, making it ideal for handling large materials and complex projects with ease. Whether you’re crafting intricate designs or working on heavy-duty production, the 1530 CNC router delivers consistent, high-quality results every time. Equipped with a robust spindle, advanced motion systems, and user-friendly software, the 1530 CNC router ensures unparalleled accuracy and efficiency. Its high-speed cutting capabilities reduce production time, while its compatibility with various materials, including wood, acrylic, and composites, expands its usability across multiple applications.

Engineered for reliability, the 1530 CNC router features a heavy-duty frame that minimizes vibration for smoother operations and a longer lifespan. Advanced safety features and customizable options further enhance its functionality, making it suitable for both beginners and seasoned professionals. Whether you’re looking to scale your business, streamline your manufacturing process, or explore creative possibilities, the 1530 CNC router combines cutting-edge technology and exceptional build quality to empower your vision. Discover the difference that precision, efficiency, and versatility can make with the 1530 CNC router.

-

AKM1530 CNC Router

Rated 5.00 out of 5$5,400.00 Add to cart -

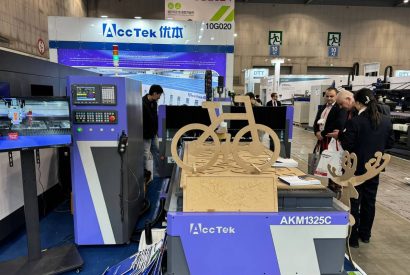

AKM1530C CNC Router

Rated 5.00 out of 5$14,000.00 Add to cart -

AKM1530-4A CNC Router

Rated 5.00 out of 5$15,600.00 Add to cart -

AKM1530C-4A CNC Router

Rated 5.00 out of 5$20,600.00 Add to cart -

AKM1530-5A CNC Router

Rated 5.00 out of 5$68,800.00 Add to cart -

AKM1530-R CNC Router

Rated 5.00 out of 5$6,100.00 Add to cart -

AKM1530-4R CNC Router

Rated 5.00 out of 5$9,600.00 Add to cart

Tips for Choosing the Right 1530 CNC Router

Selecting the right 1530 CNC router is essential for optimizing productivity, precision, and return on investment. With its 1500mm x 3000mm worktable and advanced features, this machine can handle a wide range of projects, from woodworking and signage to metal fabrication. However, to ensure you choose the best fit for your needs, it’s important to evaluate various factors, such as material compatibility, automation options, and maintenance requirements.

Define Your Application Needs

Understanding your primary applications is the first step. Are you working with wood, metal, or acrylic? Will your projects require intricate detailing or heavy-duty cutting? Defining your specific needs will help you identify the ideal features, such as spindle power, cutting speed, and compatibility with different materials.

Ensure Worktable Size Matches Your Projects

The 1530 CNC router’s 1500mm x 3000mm worktable is designed for larger projects, but it’s crucial to verify that this size aligns with your material dimensions and workflow. If you work on smaller-scale projects, make sure the machine offers flexibility in material placement. Features like vacuum hold-down systems help secure materials for precise, error-free operation.

Choose the Right Spindle Power

The spindle is a critical component of any CNC router. For denser materials like aluminum or hardwood, a spindle with at least 6kW power is recommended. For lighter applications, such as foam or softwood, a less powerful spindle may suffice. Choosing the right spindle ensures efficiency without overloading the machine or compromising quality.

Examine the Motion System

The motion system directly affects the CNC router’s speed and precision. Ball screw systems provide exceptional accuracy for detailed work, while rack-and-pinion systems offer faster movement for large-scale production. Evaluate your production needs to choose the motion system that balances speed and precision for optimal performance.

Verify Material Compatibility

Not all CNC routers are designed to handle every material. Ensure the 1530 CNC router you choose can cut, engrave, or mill the materials you frequently use, such as wood, acrylic, composites, or metals. A machine with versatile material compatibility allows you to diversify your offerings and tackle various projects.

Look for Software Compatibility

The software that powers your CNC router is as important as the hardware. Ensure the machine integrates seamlessly with intuitive CAD/CAM software that meets your skill level and project requirements. Robust software simplifies design creation, file conversion, and CNC router operation, especially for complex tasks.

Prioritize Build Quality and Stability

A well-built CNC router is essential for precision and durability. Look for a machine with a heavy-duty steel frame, which minimizes vibrations during operation and ensures consistent performance over time. High build quality also enhances reliability, reducing downtime and maintenance costs.

Focus on Speed and Precision

Cutting speed and accuracy are critical factors, especially for time-sensitive projects. High-speed CNC routers reduce production time, while precise motion systems ensure detailed cuts and smooth finishes. Compare specifications like maximum cutting speed and repeatability to find a balance that suits your workflow.

Check for Safety Features

Safety is a top priority when working with CNC routers. Look for essential features like emergency stop buttons, protective shields, and dust collection systems. These not only protect operators but also create a safer, cleaner work environment, which is particularly important in busy workshops.

Evaluate Maintenance Needs

Machines with minimal maintenance requirements save time and reduce operational costs. Look for features like automated lubrication systems, accessible components, and efficient dust management. Easy maintenance ensures your CNC router stays in optimal condition and extends its lifespan.

Explore Automation Features

Automation options like automatic tool changers (ATCs) and material handling systems can significantly boost efficiency and productivity. These features reduce manual intervention, streamline workflows, and are especially beneficial for businesses with high-volume or complex production requirements.

Factor in Budget and ROI

When choosing a 1530 CNC router, consider your budget alongside the machine’s long-term value. While premium models may have higher upfront costs, their efficiency, durability, and advanced features often deliver better returns on investment over time. Balance affordability with performance to ensure your purchase aligns with your growth goals.

What materials can a 1530 CNC router cut?

The 1530 CNC router is designed for versatility, offering the capability to cut, engrave, and mill a wide range of materials with precision and efficiency. Its robust spindle power and advanced cutting technology make it ideal for both soft and hard materials. Whether you’re working with wood, plastics, acrylics, or composite materials, the CNC router delivers clean, accurate cuts. It’s equally adept at handling tougher materials like aluminum and other non-ferrous metals, ensuring consistent results across diverse applications.

With its adjustable settings, the 1530 CNC router accommodates varying material densities and thicknesses, making it an excellent choice for industries like woodworking, signage, cabinetry, and metal fabrication. Its ability to handle intricate detailing and heavy-duty production tasks ensures flexibility and efficiency for any project. This adaptability makes the 1530 CNC router a valuable asset for professionals looking to expand their capabilities and enhance their workflow.

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

What is CNC Router Homing and Why is It Important?

CNC router homing is a fundamental process. In this article, we'll break down what CNC router homing is, how it works, and why it's an indispensable part of every machining ...

Read More

What Should I Consider When Buying a CNC Router from an Overseas Supplier?

In this guide, we’ll walk you through the key considerations when buying a CNC router from an overseas supplier to help you make a confident and informed decision.

Read More

How to Choose the Right Vacuum Pump for a CNC Router Vacuum Table?

This guide will walk you through the factors to consider when choosing a vacuum pump for your CNC router vacuum table, helping you make an informed decision based on your ...

Read More

How Do I Ensure Electrical Safety with a CNC Router?

In this article, we'll explore the key steps to ensure the electrical safety of CNC routers, from proper installation to operator training, to provide you with guidance to ensure electrical ...

Read More

Frequently Asked Questions

What Are 1530 CNC Routers Used For?

The 1530 CNC router is a versatile machine used across various industries for cutting, engraving, and milling materials with precision and efficiency. In woodworking, it’s ideal for crafting furniture, cabinetry, decorative panels, doors, and intricate carvings. For signage and advertising, it enables the creation of custom signs, logos, and dimensional letters in materials like acrylic, and wood. It’s also used in plastics and composite machining, where it excels at creating fixtures, molds, and precision parts.

The 1530 CNC router’s large worktable and precise motion system make it suitable for cutting large sheets of material for flooring, wall panels, and structural components. Additionally, its ability to handle 3D designs allows for intricate sculpting, prototyping, and product design across industries such as architecture and engineering. Its adaptability to various materials and applications makes it a go-to solution for businesses and professionals seeking high-quality, repeatable results.

How Much Are 1530 CNC Routers?

The price of a 1530 CNC router depends on its configuration, features, and capabilities. Here’s an overview of the price ranges:

- 3-Axis CNC Router: $3,000 – $6,500. These basic models are ideal for standard cutting and engraving tasks, offering reliable performance at an affordable cost.

- ATC CNC Router (Automatic Tool Changer): $6,000 – $20,000. Designed for efficiency, these machines allow automatic tool changes, making them suitable for complex and multi-tool projects.

- 4-Axis CNC Router: $10,000 – $18,000. With enhanced rotational capabilities, these CNC routers are perfect for advanced 3D carving and intricate designs.

- 4-Axis ATC CNC Router: $19,000 – $25,000. Combining 4-axis functionality with automatic tool changing, these machines are tailored for high-precision, large-scale 3D machining.

- 5-Axis CNC Router: $55,000 – $70,000. The most advanced option, offering full 5-axis motion for intricate and high-precision applications, including aerospace and automotive components.

- Rotary Axis CNC Router: $5,000 – $15,000. Specialized for cylindrical material cutting, these CNC routers are ideal for creating spindles, columns, and other rounded designs.

How Precise Are 1530 CNC Routers?

1530 CNC routers are highly precise machines, capable of achieving tolerances as tight as ±0.05mm or better, depending on the model and setup. Their precision comes from advanced motion control systems, such as ball screws or rack-and-pinion drives, which ensure smooth and accurate cutting. Additionally, features like high-powered spindles, rigid frames, and dynamic toolpath optimization further enhance accuracy during operation.

The level of precision also depends on factors like material type, tool quality, and machine calibration. With proper maintenance and configuration, 1530 CNC routers consistently deliver precise results, making them ideal for intricate designs, detailed carvings, and high-quality production.

Do 1530 CNC Routers Support Adding Accessories?

Yes, 1530 CNC routers are highly versatile and support a variety of accessory upgrades to enhance functionality and expand their applications. Some of the most popular accessories include:

- Rotating Axis: Ideal for machining cylindrical objects such as spindles, columns, and pipes.

- 360° Rotating Cutting Saw: Enables precise angular and cross-cutting of materials.

- Drilling Unit: Adds efficient vertical and horizontal drilling capabilities for advanced woodworking and cabinetry.

- Oscillation Knife Head: Perfect for cutting flexible materials like foam, rubber, and textiles.

- Plasma Cutting Head: Transforms the router into a powerful tool for cutting metals with high precision.

- Auto Loading & Unloading Device: Speeds up material handling, boosting efficiency in high-volume production.

How to Maintain 1530 CNC Routers?

Proper maintenance of a 1530 CNC router ensures optimal performance, extends its lifespan, and minimizes downtime. Here are key steps for maintaining your machine:

- Regular Cleaning: Clean the worktable, spindle, and cutting area after every use to remove dust, debris, and residue that could interfere with operations. Use a vacuum or compressed air to clean hard-to-reach areas.

- Lubrication: Apply lubrication to linear guides, ball screws, and other moving parts regularly to reduce friction and prevent wear. Use manufacturer-recommended lubricants for best results.

- Inspect the Spindle and Tools: Check the spindle and cutting tools for wear or damage. Replace dull or damaged tools to maintain precision and avoid unnecessary stress on the machine.

- Check and Tighten Components: Periodically inspect screws, bolts, and belts for looseness or wear. Tighten or replace them as needed to ensure smooth and accurate movement.

- Test Motion Systems: Run calibration tests to ensure the router’s motion systems, such as ball screws or rack-and-pinion drives, are functioning properly. Address any misalignments or inconsistencies.

- Maintain Software and Firmware: Keep the CNC router’s software and firmware updated to access new features and fix bugs. Backup settings before updates to avoid losing important configurations.

- Dust Collection System Maintenance: Clean or replace filters in the dust collection system to maintain its efficiency and prevent clogging.

- Electrical System Check: Inspect wiring, connectors, and sensors regularly for signs of wear, corrosion, or damage. Replace faulty components to avoid downtime.

- Coolant and Temperature Management: If your router uses coolant, monitor levels and replace or replenish it as needed. Ensure proper ventilation to prevent overheating.

- Operator Training: Ensure operators are trained to use the machine correctly, as improper use can lead to unnecessary wear and tear.

How Long Do 1530 CNC Routers Last?

The lifespan of a 1530 CNC router can range from 10 to 15 years or more with proper use and regular maintenance. Several factors influence the longevity of the machine:

- Build Quality: High-quality materials and components, such as a sturdy frame, reliable spindle, and precision motion systems, contribute to a longer lifespan.

- Usage Intensity: Machines used for heavy-duty production may experience more wear and tear, while those used intermittently may last longer.

- Maintenance: Regular cleaning, lubrication, and inspection of parts like linear guides, spindles, and belts are crucial to avoiding breakdowns and extending the machine’s lifespan.

- Upgrades and Repairs: Replacing worn parts, upgrading components, and keeping software up-to-date can significantly extend the router’s usability over time.

What Customer Support Do 1530 CNC Routers Provide?

1530 CNC routers come with reliable customer support options to ensure smooth operation and user satisfaction:

- Free Online Technical Support: Customers can access complimentary technical assistance through online platforms, including email, chat, or video support. This service is ideal for troubleshooting, software setup, or resolving operational issues remotely.

- Paid On-Site Training: For users requiring hands-on guidance, on-site training sessions are available at an additional cost. These sessions cover installation, operation, and maintenance to ensure optimal use of the machine.

What Is The Warranty Period of 1530 CNC Routers?

Our CNC router is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

- 3-Year Warranty for the Entire Machine: This full warranty covers any defects or malfunctions in the machine as a whole, ensuring reliable performance and longevity over time.

- 5-Year Warranty for Core Components: Key components essential for optimal machine operation are covered for 1.5 years. This includes parts that may experience wear and tear with regular use, ensuring you have support for the most vital parts of the machine.