6090 CNC Router

The 6090 CNC router is a computer numerical control (CNC) machine tool that features a screw drive mechanism. It is widely used in various industries to perform precision cutting, carving, and carving tasks on materials such as wood, plastic, and rubber. The “6090” designation usually refers to the machine’s 600mm x 900mm working area.

The 6090 CNC router is known for its versatility, with multiple configurations to meet specific manufacturing needs. The screw drive system ensures precise control of the cutting tools, resulting in a high level of accuracy and repeatability during production. These CNC routers are suitable for woodworking, signage, prototyping, and other areas where complex and detailed designs are critical. There are a variety of 6090 CNC routers on the market, allowing businesses to choose the model that meets their unique requirements, making them a valuable tool in modern manufacturing and fabrication processes.

Tips for Choosing a Suitable 6090 CNC Router

Navigating the diverse world of CNC routers can be challenging, especially when considering the specific needs of your project. We provide concise and insightful guidance to help you choose the perfect 6090 CNC router for your needs. From material compatibility to precision functionality, we cover the important aspects to support your decision-making process. Whether you’re a hobbyist or an industry professional, we’ll help you make informed choices and unlock the full potential of your machining job.

Purpose and application

Define the main purpose of the CNC router and its intended application. Consider whether you will use it for woodworking, metalworking, or other specific tasks. The machine’s capabilities should be aligned with your intended tasks to ensure optimal performance.

Material compatibility

Evaluate the types of materials you plan to use. Make sure the CNC router you choose can handle a specific material, whether it’s wood, plastic, rubber, or a combination. Check the machine’s compatibility with materials of different densities and hardnesses.

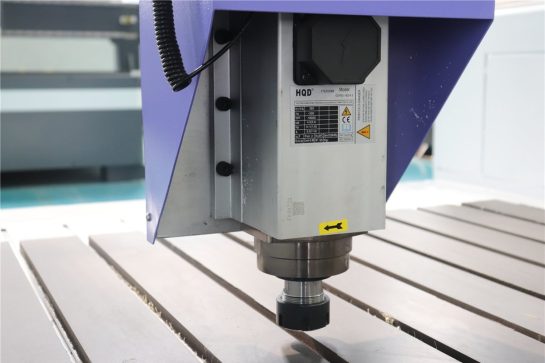

Spindle power and speed

Check the spindle power and speed specifications. Higher spindle power is suitable for machining harder materials, while adjustable speed settings provide flexibility for different tasks. Consider speed range and torque to match the spindle’s capabilities to your project requirements.

Accuracy and precision

Check the accuracy and precision features of the CNC router. The lead screw drive system commonly found in the 6090 CNC router provides greater precision. Check out additional features like ball screws, which increase the accuracy of movement along the X, Y, and Z axes.

Construction and durability

Check the manufacturing quality of the CNC router. Consider the materials used in the structure, frame stability, and overall durability. Rugged and well-built machines help increase stability, reduce vibration, and ensure consistent performance.

Easy to use

Evaluate the user interface and overall ease of use. The user-friendly control panel and intuitive software enhance your experience. Check whether the machine offers features such as tool path simulation, automatic tool changes, and simple setup procedures.

Control System

Check the control system and its compatibility with the design software. Make sure the CNC router integrates perfectly with the software you plan to use. Look for features like USB connectivity, Ethernet options, and compatibility with popular design programs.

Drive System

Determine the type of drive system used by the CNC router. Screw drive systems offer greater accuracy compared to belt drive systems. Assess the importance of accuracy in the project and select the drive system accordingly.

Speed and feed rate

Check the CNC router’s speed and feed rate capabilities. Optimal speed and feed settings contribute to efficient machining. Consider how these factors integrate with your project needs to ensure timely, accurate results.

Support and maintenance

Check customer support, documentation, and spare parts availability. Make sure the manufacturer or dealer provides adequate support for troubleshooting and maintenance. Consider whether spare parts are easily available to minimize downtime.

Budget considerations

Determine the budget of the CNC router. Consider not only the initial purchase cost, but also long-term expenses such as maintenance, upgrades, and potential expansion options. Balance your budget constraints with the features and functionality you need.

Comments and suggestions

Study customer reviews and seek recommendations from users with similar needs. Real-world experience provides valuable insights into CNC router performance, reliability, and any potential issues. Consider the overall user satisfaction before making a decision.

What materials can a 6090 CNC router cut?

The 6090 CNC router is a versatile machining tool capable of cutting a variety of materials. The specific materials it can handle may vary slightly depending on the CNC router’s design, spindle power, and tooling. However, in general, a 6090 CNC router can cut materials such as:

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

The Impact of Spindle Power on CNC Router Functionality

This article will delve into how spindle power affects the overall functionality of CNC routers, helping users make informed decisions based on their specific production needs.

Read More

How to Evaluate Energy Consumption and Operating Costs of CNC Router?

This article will guide you through the elements to consider when evaluating the energy consumption and operating costs of a CNC router, providing you with strategies to reduce operating costs.

Read More

How do I Choose The Right CNC Router Size and Capacity for a Specific Need?

In this article, we’ll walk you through the key considerations when determining the proper size and capacity of a CNC router, aiming to help you make an informed decision that ...

Read More

How to Choose the Perfect Woodworking CNC Router Bit

In this article, we’ll walk you through the essential factors to consider when choosing the perfect woodworking CNC router bit. We aim to help you choose the best router bit ...

Read More

Building Musical Instrument with CNC Router: A Comprehensive Guide

This article explores the role of CNC routers in musical instrument manufacturing, providing you with the basic knowledge and guidance you need to use a CNC router to manufacture musical ...

Read More

What Should I Know Before Buying a CNC Router?

This article discusses the things you need to know before buying a CNC router from multiple aspects, aiming to help you choose a machine that can improve your productivity and ...

Read More

Frequently Asked Questions

What is a 6090 CNC router?

The 6090 CNC router is a precision machining tool designed to cut, engrave, and engrave a variety of materials with high precision. The “6090” designation usually refers to the machine’s working area, which measures approximately 600mm x 900mm. These CNC routers utilize computer numerical control (CNC) technology to allow users to program and control the movement of tools with exceptional precision.

The 6090 CNC router is equipped with a spindle for fixed cutting tools and can process materials such as wood, plastics, rubber, and composites. The machine’s versatility makes it suitable for a wide range of applications, from small hobbyist projects to industrial manufacturing. The lead screw drive system in many 6090 CNC routers increases precision during operation. These CNC routers feature user-friendly interfaces and programmable features that enable users to create complex designs and prototypes efficiently. The 6090 CNC router is an invaluable tool for those looking for reliable, accurate machining solutions in different materials and applications.

How much is a 6090 CNC router?

The cost of a 6090 CNC router can vary greatly depending on its features, specifications, and additional accessories. The entry-level 6090 CNC router offers basic functionality for about $3,000. Suitable for hobbyists and small projects, these machines provide essential cutting and engraving capabilities.

For users who require more advanced functionality, an automatic tool changer (ATC) may be a valuable addition. The CNC router with ATC functionality, which automatically switches cutting tools during work, typically costs about $7,500. This feature is beneficial for tasks involving multiple tool changes, increasing efficiency and reducing manual intervention.

If your project involves cylindrical or round objects, you may need to add an axis of rotation to the 6090 CNC router. The cost of adding a rotary axis attachment to a CNC router varies widely, from $3,500 to $9,000 or more, depending on the complexity and size of the axis.

It’s worth noting that these price ranges are approximate and may vary based on factors such as brand, build quality, spindle power, and additional features. When considering a 6090 CNC router, it is recommended to carefully evaluate your specific needs and budget constraints to find the machine that best suits your requirements.

What is the voltage of this 6090 CNC router machine?

The voltage of the 6090 CNC router from AccTek CNC can be specified based on the user’s requirements, offering flexibility to accommodate different electrical systems. AccTek CNC provides options for both 110V and 220V, allowing users to choose the voltage configuration that aligns with the electrical supply available in their workspace.

Do I need to replace the collets of the 6090 CNC router?

The need to replace collets on a 6090 CNC router depends on various factors, including the type of work you are performing, the materials you are cutting, and the frequency of use. Collets are the part of the spindle that holds the cutting tool, and over time, they can experience wear and tear.

Here are some considerations regarding collet replacement:

- Wear and Tear: With regular use, collets can wear out, especially if you work with hard or abrasive materials. If you notice a decrease in cutting performance, and accuracy, or if there’s visible damage to the collet, it may be time for a replacement.

- Size Compatibility: If you plan to use cutting tools with different shank sizes, you may need to change the collet to match the tool’s diameter. Ensure that the collet size is compatible with the shank diameter of the cutting tools you intend to use.

- Collet Type: Some CNC routers use ER collets, which are known for their accuracy and versatility. These collets may last longer compared to others, but replacement may still be necessary over time.

- Tool Changes: If you frequently change cutting tools, the collet can experience additional stress. Regularly inspect the collet for any signs of damage or deformation, and replace it if necessary.

- Material Compatibility: Different projects and materials may require specific collet sizes. If you change the type or size of cutting tools frequently, you might need to swap out collets to accommodate the tooling.

- Manufacturer Recommendations: Follow the manufacturer’s guidelines and recommendations regarding maintenance and replacement of collets. They may provide information on the expected lifespan of collets and when to replace them.

- Precision and Accuracy: Worn or damaged collets can affect the precision and accuracy of your CNC router. If you notice a decline in performance or encounter difficulty in securing tools properly, it might be time to consider replacing the collets.

Can the working height of the 6090 CNC router be changed?

Yes, the working height of the AccTek CNC’s standard 6090 CNC router can be changed based on specific user requirements. The default working height for this CNC router is 200mm. However, AccTek CNC offers flexibility by providing options for different working heights. Users can choose between 150mm or 250mm working heights, allowing them to tailor the machine to their specific project needs.