Aerospace Industry

Application of CNC Router in The Aerospace Industry

CNC Router Enhanced Aerospace Production Technology

Reduce Material Waste And Costs

The CNC router optimizes material use and minimizes waste by precisely cutting and shaping components. Reduced material waste contributes to cost savings, especially for high-value aerospace materials such as titanium or advanced composites.

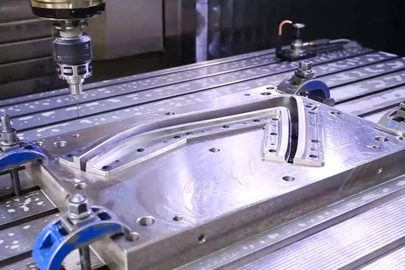

Prototyping And Rapid Tooling

CNC router enables rapid prototyping, allowing aerospace engineers to quickly iterate and test new designs. This accelerates product development cycles, facilitates design improvements, and reduces time to market for new aerospace technologies.

Composite Manufacturing

CNC router is good at cutting complex shapes and patterns with high precision. In the aerospace industry, where composite materials such as carbon fiber are prevalent, CNC routers ensure precise and consistent cuts, reducing material waste and improving the overall quality of parts.

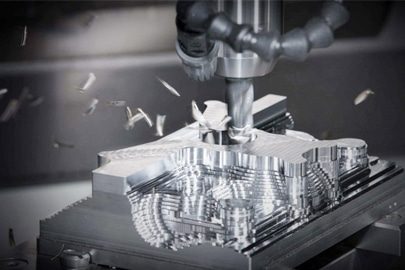

Precision Machining

CNC router brings unparalleled precision to the machining process. The machine enables precise shaping, drilling, and finishing of a wide range of materials. Its accuracy improves the quality and consistency of machined parts and helps improve the overall reliability of aerospace systems.

Interior Parts Manufacturing

CNC routers play an important role in manufacturing complex aircraft cabin interior components. Whether it's precision-cut cabinets, seating components, or decorative elements, CNC routers help customize and detail aircraft interiors to meet aesthetic and functional requirements.

Complex Molds And Molding

CNC routers are used to create molds, dies, and tooling for aerospace manufacturing processes. The precision and speed of CNC routers contribute to efficient tool production, ensure high-quality molds, and facilitate mass production of aerospace components.

Customization And Small-Batch Production

For specialty or custom aerospace components, CNC routers provide the flexibility to cost-effectively produce small batches. This capability facilitates the production of custom parts required for specific aircraft configurations or refurbishment purposes.

Repair And Maintenance Operations

During maintenance and repair operations, CNC routers help accurately replicate damaged or worn parts. This ensures that replacement parts meet original specifications, contributing to the safety and reliability of the aircraft during continued operations.