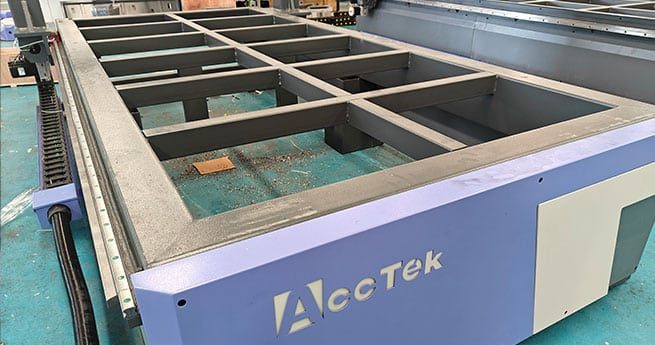

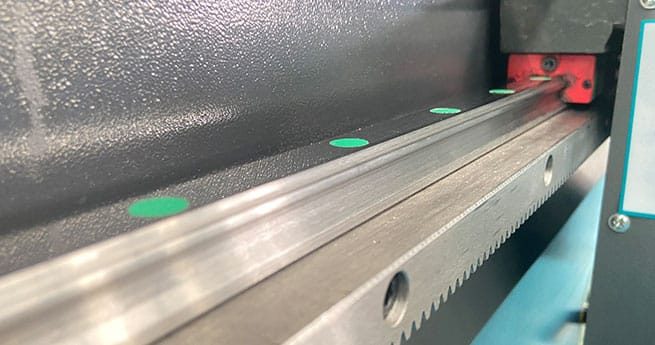

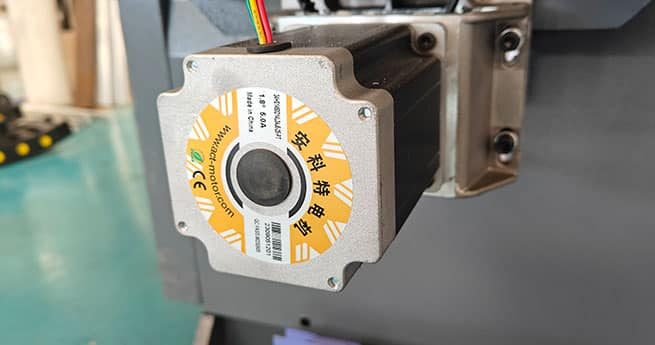

Heavy Duty 4040 Metal CNC Router

The AK4040H CNC router is engineered for precise metal engraving, offering robust performance and high accuracy. Ideal for detailed metalwork, it ensures smooth and reliable results for various applications.

4 reviews for AK4040H CNC Router

Benson –

Extremely pleased with my powerful CNC router. Currently processing aluminum with remarkable precision. The machine’s capabilities have exceeded my expectations, making AccTek CNC my top choice for efficient and high-quality metal machining.

Hebe –

Highly appreciative of AccTek CNC’s professionalism during my CNC router selection process. Grateful for their guidance in choosing the best processing machine. Now that I have received it, I look forward to enjoying its capabilities. AccTek CNC is a reliable partner for precision work.

Doris –

Thrilled with my recent purchase of the AccTek CNC router! Arrived promptly, and after trying some simple procedures, it works flawlessly. Extremely satisfied, as it has become an integral part of my daily workflow, handling various tasks efficiently.

Cecil –

Pleased with our dual purchase of CNC routers from AccTek. The machines perform excellently, and the sales staff’s support has been outstanding. AccTek CNC delivers quality products and exceptional service, making them our preferred choice for CNC solutions.