2040 CNC Router

The 2040 CNC router refers to a CNC router with a working area size of 2000mm x 3000mm. These CNC routers are available in a variety of configurations to meet different machining needs. The 2040 CNC router is commonly used in woodworking, plastic processing, and other manufacturing industries to utilize computer-controlled precision to engrave, cut, or carve materials with high precision.

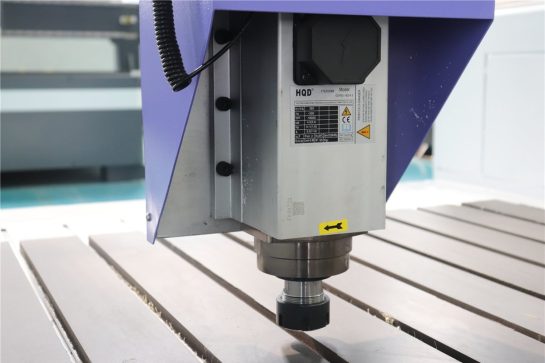

The 2040 CNC router is equipped with state-of-the-art features such as high-speed spindle options, advanced tool changers, and precision motion control systems to ensure efficient and accurate machining processes. Compatible with a variety of materials including wood, rubber, and plastic, these CNC routers find applications in the woodworking, aerospace, automotive, and prototyping industries. The versatility and technical prowess of the 2040 CNC router make it an indispensable tool for modern manufacturing, allowing companies to achieve unparalleled precision and productivity in their production processes.

Tips for Choosing a Suitable 2040 CNC Router

Navigating the world of CNC routers can be complex, and choosing the right 2040 CNC router can help facilitate a successful machining operation. We guide you through the decision-making process by providing concise yet comprehensive insights into the key factors to consider. From understanding your project requirements to evaluating spindle power, motion systems, and more, our tips are designed to give you the knowledge you need to make informed choices in your machining process for optimal accuracy and efficiency.

Understand your requirements

Start by defining the specific needs of the project. Consider the materials you will be using, the scale of the project, and the level of precision required. Understanding your requirements will guide you in selecting a 2040 CNC router with appropriate specifications.

Spindle power and speed

Evaluate the CNC router’s spindle power and speed capabilities. Higher spindle power is suitable for cutting dense materials, while variable speed options provide flexibility for different applications. Choose the CNC router that meets your application needs.

Tool changing ability

Evaluate whether your project requires the use of multiple tools. If you are working on complex projects or multiple tooling requirements, choose a CNC router equipped with an automatic tool changer. This feature increases efficiency and reduces downtime.

Exercise system

Consider the motion control system, such as the type of motor used (servo or stepper). The choice depends on the accuracy and speed required for your project. Precise and reliable motion systems help achieve precise cuts and movements during processing.

Precision and accuracy

Find detailed information on CNC router precision and accuracy specifications. Look for a CNC router with features like ball screws, linear guides, and high-resolution encoders. These help improve the precision and accuracy of the machining process.

Control System

Evaluate control system and software compatibility. A user-friendly interface and compatibility with popular CNC software will simplify programming and operation. Make sure the control system meets the technical requirements of your project.

Build quality and rigidity

Check the overall structure and rigidity of the CNC router. A sturdy frame and high-quality components help increase stability, minimize vibration during operation, and ensure long-term durability. A rigid structure improves overall machining accuracy.

Dust removal system

Consider the effectiveness of your dust collection system. Efficient dust removal helps maintain a clean working environment and extend the service life of CNC router components. Look for a CNC router with well-designed dust management features.

Easy to maintain

Evaluate the ease of maintenance. Choose a CNC router with removable components and clear documentation to perform routine maintenance tasks. This ensures your machine remains in top condition and minimizes downtime.

Manufacturer reputation and support

Research the reputation of CNC router manufacturers. Consider factors such as company history, customer reviews, and overall market position. Choose a manufacturer with a solid reputation for producing reliable CNC routers and providing excellent customer support.

Budget considerations

Determine your budget constraints and weigh them against the features offered. While staying within your budget is crucial, prioritize investing in a CNC router that meets your requirements and strikes a good balance between cost-effectiveness and performance.

View reviews and recommendations

Read customer reviews and testimonials for the specific model you’re considering. Real-world experiences from other users provide valuable insights into the actual performance, reliability, and user satisfaction of the CNC router model you are evaluating.

What materials can a 2040 CNC router cut?

The 2040 CNC router, with its size and capabilities, can cut a variety of materials across different industries. The specific materials it can handle depend on factors such as spindle power, speed, and the type of cutting tools used. Generally, a 2040 CNC router can cut materials such as:

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

The Impact of Spindle Power on CNC Router Functionality

This article will delve into how spindle power affects the overall functionality of CNC routers, helping users make informed decisions based on their specific production needs.

Read More

How to Evaluate Energy Consumption and Operating Costs of CNC Router?

This article will guide you through the elements to consider when evaluating the energy consumption and operating costs of a CNC router, providing you with strategies to reduce operating costs.

Read More

How do I Choose The Right CNC Router Size and Capacity for a Specific Need?

In this article, we’ll walk you through the key considerations when determining the proper size and capacity of a CNC router, aiming to help you make an informed decision that ...

Read More

How to Choose the Perfect Woodworking CNC Router Bit

In this article, we’ll walk you through the essential factors to consider when choosing the perfect woodworking CNC router bit. We aim to help you choose the best router bit ...

Read More

Building Musical Instrument with CNC Router: A Comprehensive Guide

This article explores the role of CNC routers in musical instrument manufacturing, providing you with the basic knowledge and guidance you need to use a CNC router to manufacture musical ...

Read More

What Should I Know Before Buying a CNC Router?

This article discusses the things you need to know before buying a CNC router from multiple aspects, aiming to help you choose a machine that can improve your productivity and ...

Read More

Frequently Asked Questions

What is a 2040 CNC router?

The 2040 CNC router is a computer numerical control (CNC) machine with a frame size of 2000mm x 4000mm. This numerical designation signifies its substantial working area, making it suitable for a wide range of machining applications. The 2040 CNC router utilizes precision-controlled movements guided by computer programming to cut, carve, and shape various materials with exceptional accuracy. Its applications span across industries, including woodworking, metalworking, plastics fabrication, and more.

Equipped with a robust frame and advanced features, the 2040 CNC router accommodates the demands of diverse projects. The machine’s versatility allows it to work with materials such as wood, plastics, non-ferrous metals, and composites. With capabilities for intricate detailing and large-scale projects, the 2040 CNC router represents a cutting-edge solution for modern manufacturing, providing efficiency, precision, and flexibility in a single, powerful tool.

What is a 2040 CNC router used for?

The 2040 CNC router is a versatile machine used for precision cutting, carving, and shaping various materials. Its applications span multiple industries, and some common uses include:

- Woodworking: Crafting furniture, cabinets, doors, and decorative woodwork with precision and intricate detailing.

- Sign Making: Engraving and cutting materials like acrylic, PVC, and wood for creating signs and displays.

- Plastics Fabrication: Cutting and shaping plastic materials like acrylic, polycarbonate, and PVC for applications in prototyping, packaging, and more.

- Foam Cutting: Precision cutting of foam materials for packaging, insulation, and model-making purposes.

- Composite Material Machining: Working with composite materials like fiberglass and carbon fiber for applications in aerospace, marine, and automotive industries.

- Prototyping: Creating prototypes and models with high precision for product development and testing.

- Architectural Millwork: Manufacturing architectural elements, such as moldings, trim, and decorative features, with intricate designs.

- Educational Purposes: CNC routers are commonly used in educational settings to teach students about computer-controlled machining processes.

- Custom Fabrication: Supporting small-scale and custom manufacturing by enabling efficient production of unique components and products.

How much is a 2040 CNC router?

The cost of a 2040 CNC router can vary significantly based on its features, capabilities, and additional accessories. Here’s a breakdown of estimated prices for different configurations:

- Entry Level ($7,000): Basic 2040 CNC routers without advanced features or accessories typically fall into this price range. These machines are suitable for simpler tasks and may have manual tool changes.

- ATC (Automatic Tool Changer) ($14,000-24,000): CNC routers equipped with an Automatic Tool Changer, allowing for efficient and automatic switching between different cutting tools. The price range depends on the specific features, tool capacity, and brand.

- 4-Axis ($17,000-24,000): 4-axis CNC routers add Spindle rotational capability to the standard X, Y, and Z axes, enabling more complex machining operations. Prices vary based on factors such as spindle power, build quality, and additional features.

- Rotary Axis ($8,000-26,000): CNC routers with a rotary axis are designed for cylindrical or 3D carving applications. The cost depends on the rotational capabilities, build quality, and compatibility with different materials.

Can the working height of the 2040 CNC router be customized?

Yes, the working height of the 2040 CNC router can be customized to meet specific customer requirements. AccTek CNC is known for providing highly customizable solutions tailored to individual needs. This involves adjusting the Z-axis or working height to accommodate different thicknesses of material or to meet unique project specifications.

Customers working with AccTek CNC have the flexibility to discuss their specific requirements with us, resulting in a more personalized solution. AccTek CNC is committed to customization, allowing users to adjust the CNC router to their specific application, ensuring it fits precisely the needs of their project.

If you have specific preferences or requirements for the custom work height of your 2040 CNC router, you can contact us at any time. We can provide insight into the customization options available, guide you through the process, and ensure the CNC router is suitable for your unique machining needs.

How long does a 2040 CNC router last?

The lifespan of a 2040 CNC router can vary based on several factors, including usage intensity, maintenance practices, build quality, and technological advancements. Generally, a well-maintained and high-quality 2040 CNC router can last for a decade or more in an industrial setting.

Here are some factors that can influence the lifespan of a CNC router:

- Build Quality: A well-constructed and durable CNC router with high-quality components is likely to have a longer lifespan. Routers made with robust materials and precise engineering tend to withstand the rigors of regular use.

- Maintenance: Regular and proper maintenance significantly influences the longevity of a CNC router. Following the manufacturer’s maintenance guidelines, cleaning components, lubricating moving parts, and addressing any issues promptly can extend the machine’s life.

- Usage Intensity: The frequency and intensity of usage impact a CNC router’s lifespan. Heavy industrial use may lead to more wear and tear compared to occasional or light use.

- Technological Advances: Rapid advancements in CNC technology may lead to the obsolescence of older models over time. While the core functionality of a CNC router may remain relevant, newer models might offer enhanced features and capabilities.

- Manufacturer Reputation: The reputation of the manufacturer plays a role. Routers from reputable manufacturers with a history of producing reliable and durable machinery are likely to have a longer lifespan.

- Upgradability: Some CNC routers are designed with upgradability in mind, allowing users to update certain components or features. This can extend the useful life of the machine.