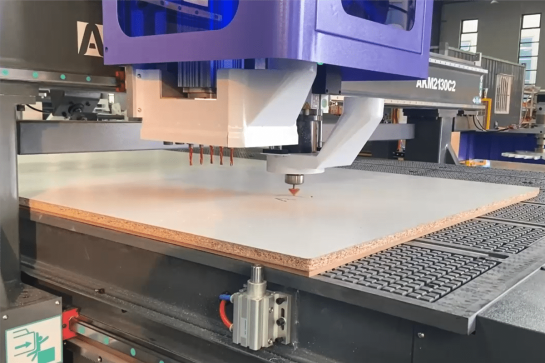

1325 CNC Router

The 1325 CNC router is a versatile, high-performance machining tool widely used in woodworking, metalworking, and other manufacturing applications. The machine features a 1300mm x 2500mm work area, providing a spacious platform for precision cutting, engraving, and engraving. It uses computer numerical control (CNC) technology to enable automated, high-precision cutting, carving, and engraving of materials such as wood, plastic, and ceramics.

The 1325 CNC router has a sturdy frame and an advanced control system to ensure stability and consistency in its operation. Its high-speed spindle and advanced motion control enable complex and detailed designs, making it the first choice for furniture manufacturing to signage production tasks. The user-friendly interface of this CNC router facilitates easy programming and operation, making it easy to use by both experienced professionals and novices in the field of CNC machining. The reliability and efficiency of the 1325 CNC router make it a popular choice for small workshops and industrial production environments, helping to increase the productivity and quality of the manufacturing process.

Tips for Choosing a Suitable 1325 CNC Router

Choosing the right CNC router is crucial to the accuracy and efficiency of material processing. We’ll provide expert insights and practical advice on key considerations when choosing a 1325 CNC router. Whether you’re delving into woodworking, plastics processing, or another application, these tips will help you make an informed decision and ensure your CNC router fits your project requirements seamlessly.

Material compatibility

Make sure the CNC router you choose is compatible with the materials you plan to use. Consider the machine’s ability to handle a variety of materials, such as wood, plastic, or composites. Verify the spindle’s ability to cut the selected material and the availability of additional accessories for special applications.

Spindle power and speed

Evaluate spindle power and speed options based on your intended application. Higher spindle power helps cut tougher materials, while adjustable spindle speed allows versatility in different tasks. Consider the CNC router’s RPM (revolutions per minute) range to make sure it meets the requirements of your specific project.

Accuracy and precision

Look for a CNC router with features that increase accuracy and precision. Consider using a machine with ball screws, high-quality linear guides, and a rigid frame to minimize vibration. Check feedback systems such as encoders that facilitate precise positioning to ensure the CNC router delivers consistent and accurate results.

Control system and software

Evaluate control system and software compatibility. Check if the machine is compatible with your favorite CAD/CAM software. The user-friendly control system simplifies operation and shortens the operator’s learning curve. Verify that the controller allows for easy customization of cutting parameters, and evaluate how easily programs can be transferred from the design software to the CNC router.

Construction and durability

Check the structure and rigidity of the machine frame. A sturdy frame, high-quality materials, and sturdy construction contribute to stability during operation. Look for features like stress-relief frames to minimize distortion over time. Durable components ensure longer life and consistent performance.

Tool replacement and compatibility

Consider the tool-changing mechanism and the CNC router’s compatibility with different tools. CNC routers with automatic tool-changing systems increase efficiency and versatility, allowing seamless transitions between different cutting tools. Validate tool holder specifications to ensure compatibility with various cutting tools for process flexibility.

Dust removal system

Evaluate the effectiveness of dust collection systems. Efficient dust collection helps maintain a clean working environment and protects machine components. Look for a CNC router with a well-designed dust cover and collection system to minimize dust accumulation and ensure optimal performance.

Exercise system

Consider the type of motion system used by the CNC router. High-quality motion systems, such as ball screws or rack and pinion drives, contribute to smooth and precise movements. Evaluate the type of motor used (stepper or servo) and its impact on speed, torque, and overall performance.

Easy to maintain

Evaluate the ease of maintenance of the CNC router. Look for features like easy access to key components, simple calibration procedures, and user-friendly maintenance procedures. Maintaining machines with minimal downtime helps increase productivity.

Support and training

Check the manufacturer’s reputation for customer support and training. Ensure comprehensive training materials, manuals, and technical support are always available. Manufacturers with responsive customer service can help resolve issues and optimize the performance of your CNC router.

Comments and suggestions

Research customer reviews and seek advice from industry professionals. Insights from users with hands-on experience with a specific model can provide valuable information about machine performance, reliability, and potential challenges.

Budget considerations

Evaluate CNC router cost while considering all features. Compare prices from different brands while keeping in mind your budget constraints. The goal is to find a machine that offers the best balance of functionality and affordability to meet your specific needs.

What materials can a 1325 CNC router cut?

The 1325 CNC router is versatile and capable of cutting a wide range of materials. The specific materials it can cut may vary based on factors such as the spindle power, cutting speeds, and the type of cutting tools used. Generally, the 1325 CNC router can cut:

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

How to Reduce the Impact of Workpiece Adhesion on CNC Router Cutting Quality

This article delves into practical strategies for mitigating the impact of workpiece adhesion on CNC router cutting quality, to improve the performance and reliability of CNC router operations.

Read More

Addressing Environmental Concerns in CNC Router Waste Disposal: A Comprehensive Guide

In this article, we delve into the considerations for the correct disposal of waste materials from CNC router operations, aiming to tackle the environmental challenges posed by CNC waste.

Read More

Guide to Optimizing CNC Router Parameters for Diverse Materials

This article provides a systematic parameter optimization method for CNC routers cutting different materials, aiming to provide users with the necessary knowledge to achieve excellent processing quality.

Read More

Understanding the Perils of Spindle Runout in CNC Routers

This article delves into the causes of spindle runout and strategies for mitigating its effects, aiming to provide you with the knowledge to optimize CNC router performance.

Read More

Mastering CNC Router Worktables: A Comprehensive Guide

This article delves into the CNC router types, operating methods, maintenance, and customization options, providing you with the knowledge to optimize your CNC router settings for superior results.

Read More

CNC Router Bits: Complete Buyer’s Guide

From understanding the different types of CNC router bits to deciphering the nuances of materials and coatings, this guide provides the essential reference for finding the right bit for your ...

Read More

Frequently Asked Questions

What is a 1325 CNC router?

The 1325 CNC router is a computer numerical control (CNC) machine tool designed for precise cutting, engraving, and engraving of a variety of materials. The designation “1325” usually corresponds to its working size, indicating a cutting area of 1300mm x 2500mm. This versatile tool is suitable for different industries, including woodworking, metalworking, plasticworking, and more.

The functionality of the 1325 CNC router is driven by a computer control system that interprets digital design files to guide the movement of the cutting tool (usually the spindle). The spindle rotates at an adjustable speed, allowing customization based on the material being processed. Applications for CNC routers range from making intricate wooden designs and signage to precision cutting of metal and plastic. It is a vital asset in manufacturing and prototyping, enabling high levels of accuracy and repeatability in a variety of material processing tasks.

What is a CNC router used for?

The CNC router is a versatile machine used for various tasks in different industries. Its primary function is to precisely cut, engrave, engrave, or mill materials based on computer-generated designs. Here are some common applications for CNC routers:

- Woodworking: CNC routers are widely used in woodworking for tasks like cutting, engraving, and carving intricate designs on wooden surfaces. It is used to make furniture, cabinets, decorations, etc.

- Metalworking: While CNC routers are not typically used for heavy metal cutting, they can handle softer metals such as aluminum, brass, and copper. Metalworking applications include engraving, milling, and prototyping.

- Plastic Processing: CNC routers are used to cut and shape a variety of plastics, including acrylic, PVC, and ABS. This is commonly used in sign production, plastic molding, and other applications.

- Foam Cutting: CNC router is used to cut various types of foam, including rigid foam and soft foam. It can be used in industries such as packaging, insulation, and theatrical set design.

- Signmaking: CNC routers are popular in the signmaking industry for precision cutting and engraving of materials such as acrylic, PVC, and foam to create custom signage and lettering.

- Prototyping: In product development and engineering, CNC routers are used to create prototypes of components and products. This allows designs to be tested quickly and accurately.

- Cabinet Making: In the cabinet sector, CNC routers are used to cut and shape components such as cabinet doors, panels, and intricate details, thereby simplifying the manufacturing process.

- Architectural Millwork: CNC routers are used to produce detailed architectural components such as moldings, columns, and decorative elements.

- Educational Purposes: CNC router is used in educational environments to teach students computer-aided design (CAD) and CNC machining processes and provide practical manufacturing experience.

- Stone Cutting And Engraving: A specialized CNC router equipped with diamond cutters can be used to cut and engrave stone materials such as granite and marble for architectural and artistic applications.

- Composite Material Processing: CNC routers can process composite materials such as glass fiber and carbon fiber which are common in the aerospace and automotive industries.

How much is a 1325 CNC router?

The cost of the 1325 CNC router may vary based on specifications, features, and additional features. Prices typically start at around $5,000 for an entry-level 1325 CNC router without an automatic tool changer (ATC) or additional axes. These machines are suitable for basic cutting and milling tasks, making them ideal for hobbyists and small workshops.

If you need an ATC system for automatic tool changes, the price range increases. A 1325 CNC CNC router with ATC functionality typically costs between $11,000 and $20,000. After adding ATC, the machine can automatically switch between different tools during processing, thereby improving efficiency.

For a 1325 CNC router with a 4-axis configuration, which enables more complex machining operations, the cost typically ranges from $13,000 to $20,000. The 4-axis capability allows for additional rotational motion, extending the machine’s versatility.

If you need a 1325 CNC router with a rotating axis to machine cylindrical or curved objects, the price range is $5,500 to $22,000. Cost variations are affected by factors such as the size, accuracy, and functionality of the rotary axis.

It’s worth noting that these estimates are general ranges and actual costs may depend on brand, build quality, spindle power, control system, and additional features. When considering purchasing, you can contact us. Our engineers will provide you with a custom-designed machine and quote based on the unique needs of your project. Additionally, you need to consider not only the initial purchase price, but additional costs such as software, tools, and potential maintenance fees.

What types of 1325 CNC routers are there?

1325 CNC routers are available in a variety of types and configurations, each designed to meet specific application and user requirements. Here are some common types of 1325 CNC routers:

- Standard 3-Axis CNC Router: This is the most common type, equipped with three axes (X, Y, and Z). It is suitable for basic cutting, engraving, and milling operations on materials such as wood, plastic, and ceramics.

- ATC 1325 CNC Router: Equipped with an ATC (automatic tool change) system, this type can automatically change tools during machining. It increases efficiency and is ideal for applications requiring a variety of cutting tools and a variety of cutting operations.

- 4-Axis 1325 CNC Router: The 4-axis CNC router adds an extra axis of rotation to the standard 3-axis configuration that enables the spindle to rotate. It can perform more complex machining tasks such as 3D engraving.

- Rotary Axis 1325 CNC Router: It adds a rotary axis capable of rotating the workpiece to the standard 3-axis configuration. It can be used for engraving tasks on cylindrical or curved objects.

- Multi-Axis 1325 CNC Router: The multi-axis 1325 CNC router has multiple spindles and can process multiple parts at the same time. This configuration is beneficial for mass production.

- Plasma 1325 CNC Router: Plasma 1325 CNC routers are equipped with a plasma cutting function, which can use a plasma cutting torch to cut metal materials.

- Customized Configuration: AccTek CNC can provide customized options according to user requirements, allowing customers to choose specific functions (oscillating knife, Drilling Unit, Cutting Saw, etc.), spindle power, control system, etc.