Home CNC Router

Tips For Choosing The Right Home CNC Router

Dimensions And Working Area

Material Compatibility

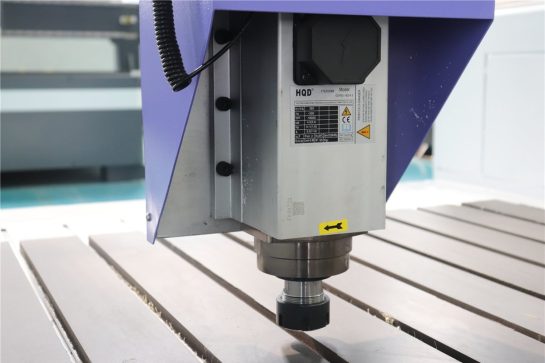

Spindle Power And Speed

Accuracy And Precision

Software Compatibility

Rigidity And Structure

Easy To Use

Upgradeability

Budget Considerations

Support And Community

Comments And Suggestions

Accessories Availability

What Materials Can A Home CNC Router Cut?

The home CNC router is a versatile tool capable of cutting various materials. The specific capabilities depend on the machine’s design, spindle power, and cutting tools. Common materials that a home CNC router can cut include:

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

The Impact of Spindle Power on CNC Router Functionality

How to Evaluate Energy Consumption and Operating Costs of CNC Router?

How do I Choose The Right CNC Router Size and Capacity for a Specific Need?

How to Choose the Perfect Woodworking CNC Router Bit

Building Musical Instrument with CNC Router: A Comprehensive Guide

What Should I Know Before Buying a CNC Router?

Frequently Asked Questions

What are home CNC routers?

How much do home CNC routers cost?

What are the risks of using home CNC routers?

- Personal Injury: Improper machine operation, improper use of cutting tools, or disregard for safety protocols can result in accidents that result in user injury. When operating machinery you need to follow safety guidelines, wear appropriate personal protective equipment, and exercise caution during operation.

- Material And Tool Hazards: Cutting tools used in CNC routers can cause injury if not handled properly. Sharp tools, high-speed rotation, and the material being cut can cause hazards. Users should receive tool safety training and ensure materials are securely fastened to prevent accidents.

- Fire Hazard: When cutting certain materials, especially plastics, there is a risk of heat and sparks being generated, which could result in a fire. Users should be careful with the materials they use and take appropriate safety measures.

- Dust And Smoke Exposure: CNC routers can generate dust and smoke, especially when cutting materials like wood or plastic. Prolonged exposure to airborne particles may cause respiratory risks. Adequate ventilation, dust collection systems, and use of respiratory protection are important precautions.

- Electrical Hazards: Improper electrical connections or component failure can cause electrical hazards. Users should ensure that the installation and maintenance of CNC routers comply with safety standards and regularly check electrical components for problems.

- Software And Programming Errors: Design or programming errors in CNC tool paths can lead to unexpected motion or cutting operations. Users should carefully check and simulate tool paths before executing them to avoid errors.

- Mechanical Failure: Over time, a CNC router’s components (such as motors, belts, or bearings) can wear out or fail. Improper maintenance or exceeding the operating limits of the machine can result in mechanical failure.

- Neglected Maintenance: Failure to maintain a CNC router regularly can lead to malfunctions, reduce its efficiency, and possibly cause accidents. Regular inspection of your machine’s components, lubrication, and calibration will help ensure safe operation.

What are the Pros & Cons of home CNC routers?

- Precision And Accuracy: CNC router provides superior precision for complex and detailed high-precision cutting, ensuring production consistency.

- Versatility: It can handle a variety of materials, including wood, plastic, metal and composites, enabling a wide range of projects and applications.

- Automation: CNC router automates the cutting process, reducing the need for manual labor and allowing users to focus on design and creativity.

- Complex Designs: Computer-aided design (CAD) integration allows users to create complex and sophisticated designs that would be challenging or impossible to implement manually.

- Repeatability: CNC routers can replicate the same design multiple times with precise consistency, ideal for mass production or creating multiple identical projects.

- Time Efficiency: Once programmed, the CNC router can quickly execute the design, speeding up the production process compared to manual methods.

- User-Friendly Interface: Many home CNC routers come with user-friendly software interfaces, allowing amateurs and DIY enthusiasts to use them without extensive technical knowledge.

- Initial Cost: A high-quality CNC router can be expensive, and the initial investment may be a barrier for some users.

- Learning Curve: Operating a CNC router requires a learning curve, especially for beginners who may need time to understand the design software, machine setup, and maintenance.

- Maintenance: Regular maintenance helps achieve optimal performance. Failure to perform routine inspection and maintenance tasks can lead to premature wear and tear.

- Safety Issues: CNC router involves rotating tools and machinery, which poses safety risks. Users are required to follow strict safety protocols, wear protective gear and adhere to machine guidelines.

- Environmental And Health Risks: Cutting certain materials may produce dust, particles or fumes that pose health risks if proper ventilation and safety measures are not taken.

- Space Requirements: Larger CNC routers may require significant workshop space, limiting feasibility for users with limited space.

- Material Waste: The precision of a CNC router can be a drawback when it comes to material waste, especially if errors are made during the design or setup process.

How to safely operate home CNC routers?

- Read The Manual: Start by thoroughly reading and understanding the CNC router manufacturer’s manual. Be familiar with the machine’s components, controls, and safety features.

- Wear Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, including safety glasses or goggles, hearing protection, and, if necessary, a dust mask or respiratory protection.

- Workspace Setup: Make sure your workspace is well-lit, organized, and free of clutter. Secure the machine to a stable surface and leave enough space around it to ensure safe movement.

- Material Preparation: Clamp or secure the material securely to the bed of the CNC router to prevent movement during cutting. Make sure it is properly aligned and positioned.

- Check Tools: Verify cutting tools are in good condition and properly seated. Use the correct tool for the material you are cutting, and replace or sharpen tools as needed.

- Dust And Smoke Management: Implement appropriate dust collection systems or ventilation to reduce airborne particles or smoke generated during cutting, especially for materials that pose a health risk.

- Machine Calibration: Calibrate the CNC router regularly to ensure accurate cutting. Check and adjust machine settings, including home and limit switches, to prevent collisions.

- Emergency Stop: Be familiar with the emergency stop function of the CNC router. Learn how to stop your machine quickly and safely if any unexpected problems arise.

- Programming And Simulation: Carefully check your CNC program for errors before running it on your machine. Use simulation capabilities in your control software to preview tool paths and detect potential problems.

- Supervision: Stay near the CNC router during operation and monitor the cutting process. Be prepared to intervene in the event of any abnormalities or emergencies.

- Training: Receive appropriate training in CNC router operation, including software use, tool replacement, and maintenance procedures. If needed, seek guidance from experienced users or professionals.

- Maintenance: Check and maintain your CNC router regularly, check for loose bolts, lubricate moving parts, and deal with any signs of wear. Follow the manufacturer’s recommended maintenance schedule.

- Electrical Safety: Make sure the CNC router is properly grounded. Avoid using the machine in wet conditions and regularly check electrical connections for signs of damage.