This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Privacy Overview

Strictly Necessary Cookies

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

3rd Party Cookies

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

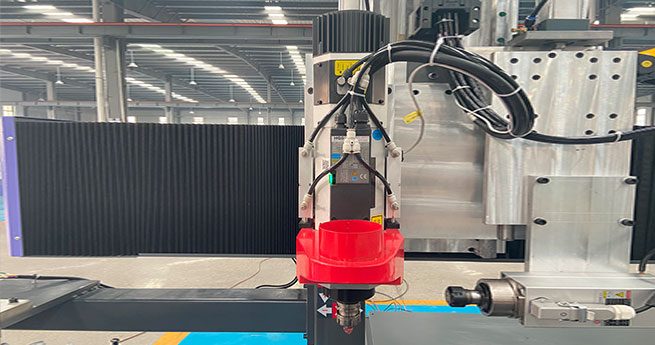

4 reviews for AKM6090C CNC Router

Edgar –

Just set up my AccTek CNC router, and it looks impressive. After testing with nested hardwood, the machine worked flawlessly. Satisfied with its performance and build quality. Highly recommend it for precision tasks.

Roxanne –

Highly satisfied with my AccTek CNC router. It operates flawlessly, exceeding my expectations. The machine’s performance and reliability are outstanding. AccTek CNC has delivered a top-notch product, and I wholeheartedly recommend them for their excellent quality and service.

Carol –

AccTek CNC surpassed expectations. The CNC router arrived in impeccable condition, installed seamlessly, and is now in operation. Thanks to their exceptional product and service, I anticipate engaging in new negotiations soon. Highly recommend it for reliability and professionalism.

Miya –

Thrilled with my AccTek CNC router! All devices are operational, and the new machine exceeded my expectations. Impressed with AccTek’s outstanding work. Highly recommend their products for quality and reliability. A great job indeed!