Commercial CNC Router

Discover precision and efficiency with our commercial CNC routers, designed to meet the rigorous demands of high-volume production. These advanced machines combine cutting-edge technology with robust engineering to provide exceptional accuracy, speed, and versatility for a wide range of industries, including woodworking, metalworking, plastics, and composites. Our CNC routers are built to handle complex designs with ease, offering the flexibility to work on materials of various thicknesses and densities. Equipped with powerful motors and precision controls, these machines ensure smooth, consistent cuts with minimal downtime. Whether you’re fabricating intricate components, creating custom designs, or processing large batches, our CNC routers deliver unmatched performance.

Featuring user-friendly interfaces and customizable settings, our commercial CNC routers are ideal for businesses looking to scale their operations without compromising quality. Designed for long-lasting durability, these machines are engineered to withstand continuous use, ensuring reliable results day in and day out. With a wide array of options and configurations available, you can choose the perfect CNC router to fit your specific needs and elevate your production capabilities to new heights. Explore our product range and experience the future of automated cutting technology.

-

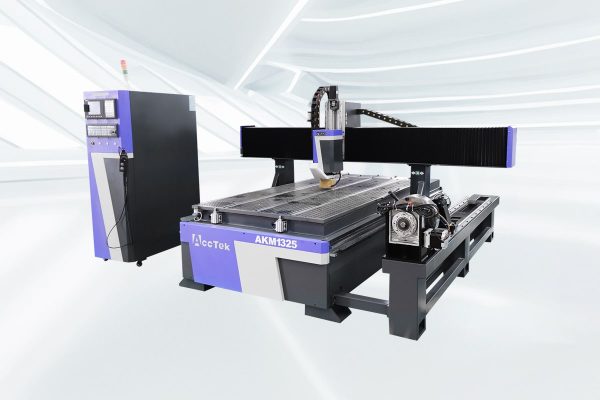

AKM1325-5A CNC Router

Rated 5.00 out of 5$61,000.00 Add to cart -

AKM1530-5A CNC Router

Rated 5.00 out of 5$68,800.00 Add to cart -

AKM1325-R CNC Router

Rated 5.00 out of 5$5,500.00 Add to cart -

AKM1530-R CNC Router

Rated 5.00 out of 5$6,100.00 Add to cart -

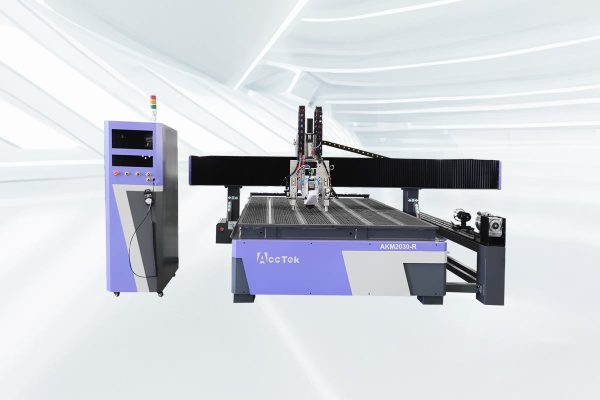

AKM2030-R CNC Router

Rated 5.00 out of 5$6,700.00 Add to cart -

AKM1325-4R CNC Router

Rated 5.00 out of 5$8,500.00 Add to cart -

AKM1530-4R CNC Router

Rated 5.00 out of 5$9,600.00 Add to cart -

AKM2030-4R CNC Router

Rated 5.00 out of 5$10,200.00 Add to cart

Tips for Choosing the Right Commercial CNC Router

Choosing the right commercial CNC router can help improve production efficiency, ensure accuracy, and meet the specific manufacturing needs of your business. With so many features and options available, it’s essential to understand the key factors that influence performance.

Determine Material Compatibility

Different materials require different CNC router specifications. If you plan to cut metals, ensure the CNC router has high torque and power. For woodworking or plastics, a lower-powered CNC router may suffice. Choosing the right machine based on the materials you use most frequently will ensure both efficiency and high-quality cuts.

Assess Cutting Area Size

The size of your cutting area directly impacts the size of the parts you can manufacture. Choose a CNC router with a cutting area that accommodates your largest materials and projects. If you’re planning to work with larger components in the future, consider a model with an expansive cutting bed.

Evaluate Spindle Power

Spindle power is a crucial factor in determining how quickly and efficiently a CNC router can cut. A higher horsepower spindle is essential for tougher materials like metals, while a lower-powered spindle will be sufficient for softer materials like wood or plastics. Choose according to the materials you intend to process.

Check Precision and Accuracy

Accuracy is vital for high-quality cuts and intricate designs. Look for a CNC router with tight tolerances and minimal backlash. A machine with high precision ensures that each cut matches the design specifications, reducing material waste and the need for rework.

Consider Build Quality

A strong, durable build ensures long-term reliability and minimal maintenance. CNC routers with a rigid frame and robust components reduce vibrations, which can affect the quality of your cuts. Choose a machine with solid construction to guarantee consistent performance, especially during extended operation hours.

Look for Automation Features

Automation features such as automatic tool changers, material handling, and nesting software improve productivity and reduce manual labor. Tool changers, for example, can streamline setup times, while nesting software optimizes material usage. These features increase production efficiency and allow for faster turnaround times on large projects.

Ensure Software Compatibility

Compatibility with your existing design software is essential for smooth operation. Ensure the CNC router supports popular CAD/CAM software, allowing for seamless transfer of designs and tool paths. A user-friendly interface and intuitive software also make training and operation easier, minimizing the learning curve for your team.

Prioritize Dust Collection Systems

Effective dust collection is important for both safety and machine longevity. A built-in dust collection system helps keep your workspace clean, reducing the buildup of debris that can interfere with the cutting process. It also prolongs the life of your CNC router by preventing dust from clogging critical components.

Examine Speed and Feed Rates

The right balance between speed and feed rate is key to both productivity and precision. Faster feed rates can speed up production, but they may affect the quality of cuts on intricate designs. Look for a CNC router with adjustable speed settings to tailor the machine’s performance to your needs.

Consider Customization Options

Customization options, such as adjustable tool heads, bed height, or multi-axis capabilities, increase the versatility of your CNC router. These features make the machine adaptable to various materials and applications. Choose a CNC router with customization options if you anticipate a diverse range of projects or if your needs may evolve.

Review Warranty and Support

A strong warranty protects your investment and ensures peace of mind. Look for a CNC router with comprehensive warranty coverage for critical components like motors, spindles, and control systems. Additionally, ensure the manufacturer offers responsive customer support for troubleshooting and maintenance to minimize downtime and keep your operations running smoothly.

Plan for Future Scalability

As your business grows, your production needs may change. Choose a CNC router that can scale with your operations, such as one that supports upgrades for more powerful spindles or expanded cutting areas. Scalable machines allow you to extend the lifespan of your investment and avoid the need for costly replacements down the road.

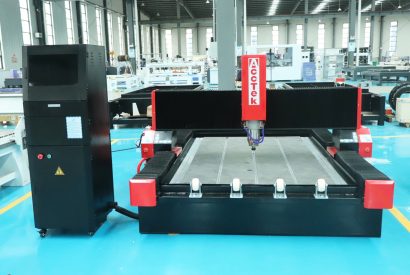

What Materials Can The Commercial CNC Router Cut?

Commercial CNC routers are versatile machines capable of cutting a wide range of materials with precision and efficiency. They are commonly used to process wood, plastic, metal, composites, and even some stone or marble surfaces. Whether you’re working with hardwoods for cabinetry, softwoods for signage, or aluminum for industrial components, a commercial CNC router can handle the job. The ability to cut different thicknesses and shapes depends on the machine’s specifications, such as spindle power and cutting area size. This flexibility makes CNC routers an essential tool in industries like manufacturing, automotive, aerospace, and woodworking, where high precision and material versatility are required.

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

What Power CNC Router Spindle Should I Choose?

In this article, we'll explore how spindle power works, what factors you should consider, and how to choose the right CNC router spindle power based on your materials and application ...

Read More

How to Choose the Right Stone CNC Router for Your Workshop?

This guide will walk you through the key factors to consider when choosing a stone CNC router, designed to help you invest wisely in a machine that delivers reliable performance ...

Read More

Best Budget CNC Router for Making Outdoor Signs?

In this guide, we'll break down the key features to look for, explore different models under a variety of price points, and help you choose the best budget CNC router ...

Read More

How to Maintain and Troubleshoot the ATC CNC Router?

This article will walk you through a practical maintenance procedure for your ATC CNC router and instruct you on how to diagnose and repair common problems that may arise.

Read More

Frequently Asked Questions

How Do Commercial CNC Routers Work?

Commercial CNC routers operate through a process known as computer numerical control (CNC), where a computer program directs the movement of the router’s cutting tools to perform precise tasks. The process begins with the creation of a digital design using CAD (Computer-Aided Design) software, which is then converted into machine-readable code using CAM (Computer-Aided Manufacturing) software. This code instructs the CNC router’s motorized axes, guiding the cutting tool along predetermined paths.

The CNC router’s spindle, equipped with various cutting tools, moves across the material—whether it’s wood, metal, plastic, or other substrates—cutting, shaping, or engraving the material based on the design. Multiple axes of movement (often 3, 4, or even 5) allow the CNC router to cut in multiple directions, providing flexibility and precision. The system is highly automated, reducing manual labor while maintaining consistent quality, speed, and repeatability for high-volume production.

What Are Commercial CNC Routers Used For?

Commercial CNC routers are highly versatile machines used across various industries for precision cutting, shaping, and engraving tasks. They are commonly used in woodworking to create cabinetry, furniture, signage, and architectural details. In the metalworking industry, CNC routers are employed for cutting and engraving metal parts, such as aluminum, brass, and steel, used in automotive and aerospace applications. Additionally, these CNC routers are used to process plastics, composites, and even foam materials for prototypes, molds, or packaging components.

CNC routers are also valuable in the sign-making industry, where they can create intricate designs for both 2D and 3D signs. Their ability to cut complex shapes with high precision makes them ideal for producing detailed artwork, logos, and decorative elements in various materials. With customizable features like automatic tool changers and multi-axis capabilities, CNC routers are designed for high-volume, repeatable production, making them essential for businesses requiring both flexibility and efficiency.

What Is The Cost of Commercial CNC Routers?

The cost of a commercial CNC router varies depending on the machine’s specifications, capabilities, and features. Here’s a general breakdown of price ranges for different types of CNC routers:

- 3-Axis CNC Routers: Typically priced between $5,500 and $8,000, these CNC routers are ideal for simpler cutting and engraving tasks.

- 3-Axis ATC (Automatic Tool Changer) CNC Routers: These advanced models range from $11,000 to $19,000, offering faster tool changes and increased efficiency for higher-volume production.

- 4-Axis CNC Routers: Priced between $12,000 and $18,000, these CNC routers provide more flexibility with an additional axis for more complex designs.

- 4-Axis ATC CNC Routers: Ranging from $20,000 to $25,000, these CNC routers feature automatic tool changing for enhanced production efficiency and accuracy.

- 5-Axis ATC CNC Routers: High-end machines for intricate, multi-dimensional cuts, typically ranging from $56,000 to $75,000.

- Rotary Axis CNC Routers: Used for specialized cutting, these CNC routers are priced between $6,000 and $12,000.

How Precise Are Commercial CNC Routers?

Commercial CNC routers are renowned for their high precision and accuracy, capable of delivering tight tolerances and consistent results. The precision of a CNC router depends on several factors, including the machine’s design, the quality of its components, and the software used. Most commercial CNC routers offer an accuracy range of 0.001 to 0.005 inches (0.025 to 0.127 mm), ensuring fine, detailed cuts even for complex projects.

The ability to repeat these precise cuts over long production runs with minimal variation is another hallmark of CNC routers, making them ideal for high-volume manufacturing where consistency is crucial. Features like backlash compensation, high-quality linear rails, and advanced control systems help reduce errors and maintain this precision. With proper calibration and maintenance, CNC routers can consistently meet the tight tolerances required for applications in industries such as aerospace, automotive, and cabinetry.

How Do Commercial CNC Routers Make Money?

Commercial CNC routers make money by increasing production efficiency, reducing labor costs, and enhancing product quality. These machines are capable of high-speed, high-precision cutting, which allows businesses to produce more parts in less time, thereby maximizing output and profitability.

CNC routers also minimize material waste through optimized cutting paths, ensuring that raw materials are used efficiently. This cost-effective production method is especially valuable in industries like woodworking, metalworking, and sign-making, where precision and volume are key factors. Additionally, the ability to automate repetitive tasks, such as tool changes and material handling, reduces the need for manual labor, allowing companies to focus on higher-value tasks.

By providing consistent, repeatable results, CNC routers enable businesses to take on large-scale orders and meet tight deadlines, which can lead to more contracts and increased revenue. Ultimately, investing in a commercial CNC router helps streamline operations, improve turnaround times, and enhance product quality—key factors that drive profitability and business growth.

How to Safely Operate Commercial CNC Routers?

Operating commercial CNC routers safely is essential to protect both the operator and the machine. Follow these key safety guidelines to ensure safe and efficient use:

- Proper Training: Ensure all operators are thoroughly trained in CNC router operation, safety protocols, and troubleshooting. Understanding the machine’s functions and controls is essential for safe operation.

- Wear Protective Gear: Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves. Depending on the material being cut, additional PPE may be necessary.

- Inspect the Machine: Before starting the CNC router, conduct a thorough inspection of the machine, checking for loose parts, proper lubrication, and signs of wear. Ensure the tool is securely attached and functioning correctly.

- Secure the Workpiece: Properly secure materials on the CNC router bed to prevent movement during operation. Loose workpieces can cause inaccurate cuts and lead to accidents.

- Use Emergency Stop Button: Familiarize yourself with the emergency stop button and ensure it’s easily accessible in case of an emergency. This will immediately halt the machine’s operation if needed.

- Avoid Loose Clothing and Hair: Never wear loose clothing, jewelry, or long hair that could get caught in moving parts. Always tie back long hair and avoid hanging accessories to minimize the risk of injury.

- Follow Manufacturer’s Instructions: Always follow the manufacturer’s operating manual for the machine’s specifications, maintenance requirements, and safety recommendations to avoid operational hazards.

- Maintain Proper Ventilation: Ensure the workspace is well-ventilated, especially when working with materials that produce fumes or dust. A dust collection system should be in place to reduce the buildup of harmful particles in the air.

- Keep the Work Area Clean: A clean and organized workspace helps prevent accidents. Remove any debris, tools, or obstructions from the work area before starting the machine.

- Perform Regular Maintenance: Routine maintenance checks, including cleaning and replacing worn parts, help ensure the machine remains in optimal working condition and prevent malfunctions that could lead to safety risks.

What Customer Support Do Commercial CNC Routers Provide?

Commercial CNC routers come with reliable customer support options to ensure smooth operation and user satisfaction:

- Free Online Technical Support: Customers can access complimentary technical assistance through online platforms, including email, chat, or video support. This service is ideal for troubleshooting, software setup, or resolving operational issues remotely.

- Paid On-Site Training: For users requiring hands-on guidance, on-site training sessions are available at an additional cost. These sessions cover installation, operation, and maintenance to ensure optimal use of the machine.

What Is The Warranty Period of Commercial CNC Routers?

Our CNC router is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

- 3-Year Warranty for the Entire Machine: This full warranty covers any defects or malfunctions in the machine as a whole, ensuring reliable performance and longevity over time.

- 5-Year Warranty for Core Components: Key components essential for optimal machine operation are covered for 1.5 years. This includes parts that may experience wear and tear with regular use, ensuring you have support for the most vital parts of the machine.