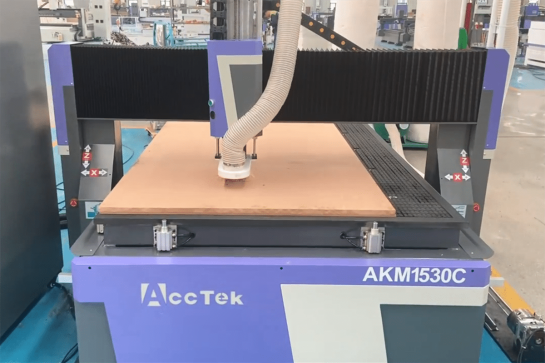

4-Axis CNC Router

The 4-axis CNC router is an advanced machining system that exceeds the capabilities of a traditional 3-axis CNC router by incorporating additional axes of motion. This fourth axis, often called the “A” axis, brings enhanced flexibility and precision to the manufacturing process. For the rotation axis, the CNC router can precisely control the rotation of the workpiece, enabling complex designs and cylindrical cutting. On the other hand, when configured as a swing axis, the A-axis controls the swing of the spindle, enabling the cutting tool to move along a curved path.

The added “A” axis makes the 4-axis CNC router ideal for applications requiring complex 3D machining, such as woodworking, metal fabrication, and prototyping. The machine’s ability to manipulate workpieces from multiple angles increases precision and opens up new possibilities for manufacturing complex, detailed parts from various materials.

Choosing The Right 4-Axis CNC Router

Choosing the right CNC router helps achieve precision machining in different industries. We’ll guide you in making an informed decision, from application requirements to key considerations in user interface design. Whether you are trying to understand complex axis configurations or evaluate spindle power, our insights are designed to help you make decisions in the world of advanced CNC machining.

Application Requirements

Start by clearly defining your processing needs. Determine the specific application you will be working on, such as complex 3D designs, cylindrical cuts, or complex contours. Determine what materials you will primarily use (wood, metal, plastic) and the accuracy required for your project. Application requirements will guide you in deciding whether a rotating or oscillating axis is more suitable for your project.

Axis Configuration

Choose a rotary or oscillating axis based on your specific application If your job involves rotating an entire workpiece, a rotary axis is ideal. On the other hand, if you need to control the movement of the spindle for complex molding, an oscillating axis may be more suitable. Choose a configuration that matches your intended design.

Precision And Accuracy

Look for a CNC router with high-resolution encoders and rugged construction to ensure machining accuracy. Precision is critical, especially for complex designs and detailed work in a variety of materials. Check for features like gap compensation to minimize errors.

Working Range Size

Assess the dimensions of the workpiece you will be working on. Choose a CNC router with a bed size and axis travel that can easily accommodate your largest projects. Make sure there is enough room to maneuver the workpiece during machining.

Spindle Power And Speed

Choose the right spindle power for your material and application. Consider the cutting speed and torque required for efficient machining. Variable spindle speed provides versatility for different materials and cutting requirements.

Tool Changing Devices And Accessories

Evaluate whether your workflow requires an automatic tool changer to increase productivity. Additionally, check to see if the machine supports accessories like a vacuum table or dust collection system, which can help create a cleaner, more efficient workspace.

Control System And Software Compatibility

Make sure the CNC router’s control system is user-friendly and compatible with the CAD/CAM software you use. Seamless integration between machine and software enables efficient operation and programming.

Build Quality And Rigidity

Check the overall build quality and rigidity of the CNC router. Sturdy construction helps maintain stability during processing, reduces vibration, and ensures consistent results. Find materials that meet the needs of your intended application.

Support And Service

Research the manufacturer or supplier’s reputation for technical support, maintenance, and spare parts availability. Reliable support and service help minimize downtime and resolve any issues that may arise.

User Interface And Training

Evaluate the user interface of the CNC router. The intuitive interface simplifies operation and shortens the learning curve. Consider the availability of training resources or support to ensure your team can use the machine effectively.

Budget Considerations

Balance your requirements with your available budget. Consider not only the initial cost but also the long-term value and return on investment. Consider the potential savings from increased productivity and efficiency.

Comments And Suggestions

Gather feedback from user reviews, and recommendations, or seek advice from industry experts. Real-world experience can provide valuable insights into CNC router performance, reliability, and overall satisfaction.

What materials can the 4-axis CNC router cut?

A 4-axis CNC router is a versatile machining tool capable of cutting a wide range of materials. The specific materials it can cut depend on factors such as the machine’s power, spindle speed, and the type of cutting tools used. Here are common materials that a 4-axis CNC router can handle:

Wood

- Pine

- Oak

- Maple

- Plywood

- MDF

- Cedar

- Teak

Plastics

- Acrylic

- PVC

- HDPE

- LDPE

- Polycarbonate

- PET

- PU

Metal

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Titanium

- Gold

Others

- Rubber

- Carbon Fiber

- Laminates

- Leather

- Glass

- Stone

- Ceramics

Application Industry

Woodworking Industry

The CNC router is a sophisticated tool that offers unparalleled precision, efficiency, and versatility, redefining what is possible in the world of woodworking.

Advertising Industry

The CNC router excels at carving, engraving, and shaping a variety of materials, from wood and plastic to metal and composites, giving advertisers a canvas as diverse as their imagination.

Bathroom Industry

The CNC router is equipped with advanced computer programming and cutting-edge machinery, ushering in a new era of efficiency, precision, and creativity in the bathroom industry.

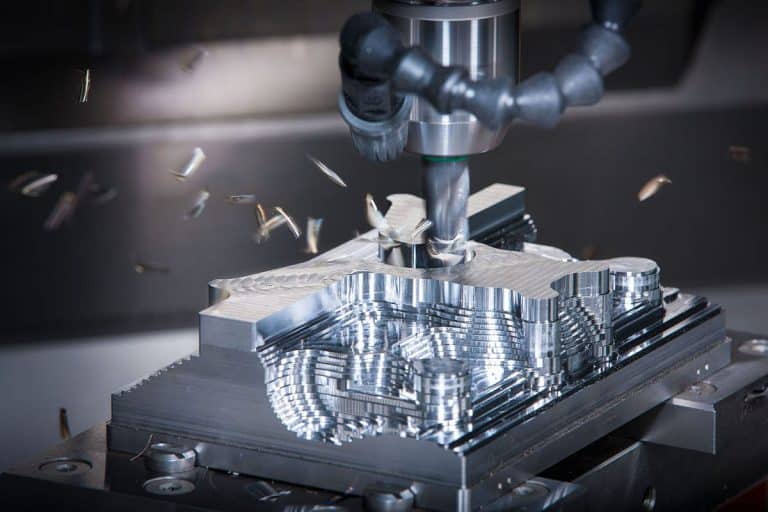

Mold Industry

The CNC router enables manufacturers to create complex, detailed molds with unparalleled precision and speed, making them an indispensable tool in the mold industry.

Blog

How to Optimize The Tool Path for CNC Router?

This article delves into the complexities of optimizing CNC router tool paths. Provides you with tool path optimization strategies to help you unleash the full potential of your CNC router.

Read More

A Comprehensive Guide to CNC Router Power Consumption

This guide analyzes the factors that affect CNC router power consumption and provides you with strategies on how to optimize power consumption without affecting productivity and quality.

Read More

What Options Does The CNC Router Support?

In this article, we delve into the diverse range of options that CNC routers support, guiding you toward making informed decisions and achieving remarkable results in your CNC endeavors.

Read More

Can CNC Routers Tackle Any Design Complexity?

CNC routers provide the means to translate designs into physical objects. However, can it tackle any design complexity? Read on to learn about the impact of CNC router performance on ...

Read More

Why Does CNC Router Need To Use A Cooling System?

This article analyzes the CNC router's heat generation to analyze the cooling system's importance in machine operation and provides you with operating precautions for these systems.

Read More

Understanding the Best File Formats for CNC Routers

In the world of CNC machining, the choice of file format holds immense significance. In this guide, we will delve into the intricacies of different file formats to guide you ...

Read More

Frequently Asked Questions

What is the 4th axis?

The 4th axis in CNC machining refers to an additional axis besides the standard X, Y, and Z axes. This axis can serve different functions, mainly as a rotary or oscillating axis:

- Axis of rotation: The axis of rotation allows the workpiece to rotate around a fourth axis of rotation. It enables the CNC router to rotate the workpiece while cutting or machining. This rotation is useful for tasks such as sculpting cylindrical objects, creating rotational symmetry, or engraving complex designs on round surfaces.

- Swing axis: Sometimes, the 4th axis can also be used as a swing axis. Rather than rotating the workpiece, a swing axis controls the movement of the spindle itself, allowing it to swing or pivot to different angles. This movement allows the machine to approach the workpiece from different angles, enhancing its ability to create complex shapes and contours.

What is a 4-axis CNC router?

The 4-axis CNC router is a computer-controlled cutting machine used for precise and automated material removal, engraving, or shaping. In addition to the standard X, Y, and Z axes in a 3-axis CNC router, a 4-axis CNC router also contains a fourth axis, usually denoted as the “A” axis. This additional axis enables additional rotational or angular movement.

The main features of the 4-axis CNC router include:

- Four-Axis Motion: In addition to the X, Y, and Z axes for horizontal, vertical, and depth motion, a 4-axis CNC router also contains a fourth axis (often denoted as the A-axis). This axis allows rotational or angular movement of the workpiece or cutting tool, thereby extending the machine’s capabilities.

- Enhanced Machining Capabilities: Added axes enable the machine to create more complex designs, complex 3D shapes, and cylindrical cuts by rotating the workpiece or controlling the movement of the cutting tool.

- Application Versatility: The 4-axis CNC router is suitable for woodworking, metalworking, prototyping, and industries requiring complex 3D machining. It is used to create surfaces, sculptures, molds, and components with rotational or angular features.

- Precision And Automation: These machines offer high precision and repeatability in cutting, engraving, and milling operations. Computer control enables automated, efficient production processes.

- Applications: The 4-axis CNC router is versatile and can be used in a variety of industries, including woodworking, metalworking, plastics processing, and prototyping. It is particularly useful in tasks involving complex 3D engraving, engraving, or production of rotationally symmetric parts.

How much is a 4-axis CNC router?

The 4-axis CNC router can vary greatly based on a variety of factors, such as machine size and configuration, brand and manufacturer, features and functionality, additional accessories, and software. Generally speaking, the price of AKM1325-R CNC router is US$5,000-5,500, while the price of AKM1325C-4A CNC router is US$19,000-23,000. It’s worth noting that these are general estimates only and actual prices may vary based on specific requirements, brand reputation, and additional features.

When determining which machine is suitable for your requirements, it is important to consider your specific needs, the type of materials you will be working with, and the complexity of the project. Additionally, costs may include accessories, tools, software, and any necessary training or support services.

What are the pros and cons of a 4-axis CNC router?

Advantages of 4-Axis CNC Router:

- Enhanced Functionality: The ability to rotate or oscillate the workpiece allows for more complex machining operations, enabling the creation of complex 3D designs and surfaces.

- Greater Versatility: A 4-axis CNC router is more versatile than a 3-axis CNC router, providing greater flexibility in handling a variety of materials and producing a wider range of shapes.

- Efficiency For Complex Designs: It excels in tasks requiring rotational or angular movement, making it suitable for tasks such as engraving cylindrical objects or engraving rotating patterns.

- Improved Surface Finish: The ability to approach the workpiece from different angles can result in a better surface finish, especially in applications where a smooth finish is critical.

- Rotational Symmetry: Ideal for tasks that require rotational symmetry, such as machining cylindrical parts, engraving round objects, or creating artwork.

- Improved Precision: With additional axes, these CNC routers allow for greater precision and accuracy, especially when creating symmetrical designs or engraving round surfaces.

- Cost: 4-axis CNC routers tend to be more expensive than 3-axis CNC routers, both in terms of initial purchase cost and potential maintenance costs.

- Complex Programming: Operating a 3-axis CNC router may require more advanced programming skills than a 4-axis CNC router, especially when dealing with complex designs and rotational motions.

- Space Requirements: Some 4-axis CNC routers may require more space due to their increased range of motion, which may be a consideration for smaller shops.

- Maintenance And Repair: Additional moving parts (rotating or oscillating axes) may require more maintenance, and repairs may be more complex than those of a 3-axis CNC router.

- Learning Curve: Operators may require additional training to fully utilize the capabilities of the 4-axis CNC router, which may result in a steeper learning curve.

- Limited Use With Certain Designs: While useful for certain designs that require rotational or angular precision, not all projects can benefit significantly from the addition of an axis, which may make it overkill for simpler designs.

What is the difference between a 3-axis, 4-axis, and 5-axis CNC router?

The difference between 3-axis, 4-axis, and 5-axis CNC routers lies in the number of axes of motion and their capabilities in machining operations:

3-Axis CNC Router

- Axes of Motion:

- X-axis: Left to right movement.

- Y-axis: Front-to-back movement.

- Z-axis: Up and down movement.

- Capabilities:

- Limited to three directions of motion, suitable for flat or three-dimensional workpieces with relatively straightforward geometries.

- Cannot perform rotations or angled cuts without repositioning the workpiece.

- Applications:

- Used for tasks where designs are primarily flat or require cuts in only three directions.

- Commonly employed in woodworking, cutting sheet materials, and basic milling operations.

- Axes of Motion:

- X-axis: Left to right movement.

- Y-axis: Front-to-back movement.

- Z-axis: Up and down movement.

- A-axis: Rotation or swinging motion.

- Additional Capability:

- Introduces a fourth axis (A-axis), enabling rotational or swinging motion of the workpiece or spindle.

- Suitable for more complex designs, allowing for the creation of cylindrical or curved shapes.

- Applications:

- Ideal for tasks involving rotational features, such as engraving cylindrical objects, carving intricate designs on rounded surfaces, or producing parts with rotational symmetry.

- Widely used in industries like woodworking, metalworking, prototyping, and manufacturing for more versatile and intricate machining operations.

- Axes of Motion:

- X-axis: Left to right movement.

- Y-axis: Front-to-back movement.

- Z-axis: Up and down movement.

- A-axis: Rotation or swinging motion.

- B-axis: Tilting or swiveling motion.

- Additional Capability:

- Introduces a fifth axis (B-axis), allowing the spindle or workpiece to tilt or swivel.

- Enables machining from various angles without repositioning the workpiece, offering greater flexibility in complex machining operations.

- Applications:

- Ideal for intricate and complex designs that require machining from multiple angles.

- Used in industries such as aerospace, automotive, mold making, and medical industries for high-precision parts with complex geometries.