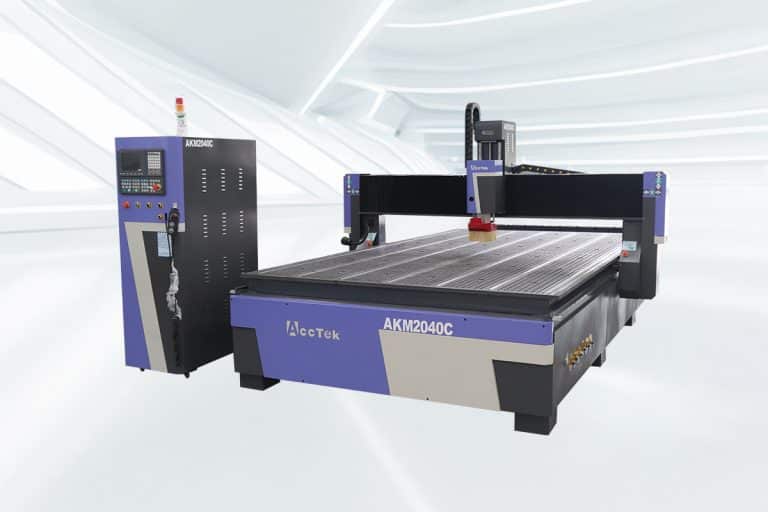

2040 CNC Router

The 2040 CNC router is a high-precision, industrial-grade solution designed to meet the demands of professionals and businesses seeking top-tier performance in CNC machining. With its robust 2000mm x 4000mm working area, this machine offers unmatched versatility for large-scale projects, making it ideal for industries such as woodworking, metal fabrication, signage, and prototyping. Engineered for precision and durability, the 2040 CNC router boasts a heavy-duty steel frame that minimizes vibrations for superior accuracy. Its advanced motion control system ensures smooth, consistent operation, even during complex machining processes. The machine supports a wide range of materials, including wood, plastics, composites, and soft metals, enabling you to bring your most ambitious designs to life.

Equipped with a powerful spindle, automated tool-changing capabilities, and cutting-edge software compatibility, the 2040 CNC router streamlines production workflows while reducing downtime. Whether you’re carving intricate details, or cutting through tough materials, this CNC router delivers speed, reliability, and exceptional results. For those who demand efficiency without compromising quality, the 2040 CNC router is a game-changer. Its user-friendly interface and compatibility with popular CAD/CAM software make it accessible for both seasoned professionals and those new to CNC technology. Experience the perfect blend of precision, performance, and productivity with the 2040 CNC router.

Tips for Choosing the Right 2040 CNC Router

Choosing the right 2040 CNC router is a critical step to ensure your projects are completed efficiently, accurately, and cost-effectively. With a range of features, specifications, and options available, it’s important to match the machine’s capabilities to your production goals. Whether you’re focusing on woodworking, metal fabrication, or other applications, understanding what to prioritize will make the decision process smoother.

Understand Your Project Requirements

Evaluate the types of projects you plan to undertake. Are you focusing on detailed engraving, large-scale cutting, or 3D machining? Each application may demand specific features like high spindle speeds for precise carving or a vacuum table for material stability. Clearly defining your needs will ensure you choose a CNC router that can handle your workload without compromise.

Match the CNC Router to Your Materials

Identify the materials you’ll work with most frequently—wood, plastics, composites, or metals—and confirm the CNC router supports them. Machines with adjustable spindle speeds and advanced tooling capabilities are more versatile, enabling you to handle a wider variety of materials. For tougher materials like aluminum, ensure the machine has sufficient power and cooling systems.

Prioritize Precision and Accuracy

For intricate designs, high precision is essential. Look for CNC routers equipped with advanced motion systems, such as ball screws or linear rails, to achieve precise cuts and consistent results. A sturdy, well-built machine will minimize vibrations and enhance cutting accuracy, even on complex patterns.

Evaluate Spindle Power and Speed

The spindle is a key component in CNC machining. Higher spindle power, typically measured in kilowatts (kW), is needed for cutting harder materials or high-volume operations. Adjustable RPM settings are also important for flexibility in processing different materials. Choose a spindle that aligns with your production goals for optimal performance.

Check the Build Quality

A durable frame made of steel or cast iron ensures the CNC router can withstand heavy use without compromising accuracy. Poorly constructed machines may experience instability, affecting the quality of cuts. A solid, vibration-resistant build is essential for maintaining precision in demanding applications.

Consider the Workspace Size

The 2040 CNC router offers a large working area (2000mm x 4000mm), but ensure it suits your specific project sizes. If you work with oversized materials or require additional fixtures, confirm the machine’s table size and configurations meet your needs. Expandable or modular tables can provide added flexibility.

Ensure Software Compatibility

Software is the backbone of CNC machining. Make sure the CNC router is compatible with popular CAD/CAM software like AutoCAD, Fusion 360, or VCarve. User-friendly software simplifies design and toolpath programming, enabling you to maximize the machine’s capabilities with minimal effort.

Look for Automation Features

Automation enhances productivity by reducing manual intervention. Features like an automatic tool changer (ATC), vacuum hold-down system, and dust extraction are invaluable for high-volume production. These capabilities streamline workflows, improve material stability, and ensure clean, efficient operations.

Analyze the User Interface

A user-friendly control system makes operating the CNC router easier, especially for teams with varying skill levels. Touchscreen interfaces, clear displays, and intuitive controls minimize learning curves and reduce errors, ensuring smoother workflows and faster project completion.

Assess Maintenance and Support

Choose a CNC router with minimal maintenance requirements and accessible technical support. Look for machines with a good warranty, easily replaceable parts, and a reliable support network. Regular maintenance ensures your machine stays in top condition, minimizing downtime and maximizing productivity.

Check Power Requirements

CNC routers can have demanding power needs, particularly industrial models. Confirm your workshop has the appropriate electrical setup to support the machine. Some CNC routers may require three-phase power, so it’s essential to verify compatibility with your facility’s infrastructure.

Balance Cost and Value

While price is a key factor, consider the machine’s long-term value. A higher initial investment in a quality CNC router with advanced features can yield better returns through increased efficiency, durability, and reduced operating costs. Evaluate the total cost of ownership to ensure a solid return on investment.

What Materials Can the 2040 CNC Router Cut?

The 2040 CNC Router is designed for exceptional versatility, enabling it to cut and shape a wide variety of materials with precision and ease. From softer materials like wood, plastics, and foam to tougher substances such as composites, acrylics, and certain metals, this machine delivers consistent results across applications. Its robust spindle and customizable tooling options make it ideal for intricate detailing, smooth carving, and heavy-duty cutting tasks. Whether you’re crafting furniture, signage, prototypes, or industrial components, the 2040 CNC router ensures clean cuts and superior finish quality. Its adaptability to diverse materials makes it a powerful tool for both creative and industrial-scale projects.

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

Advancements in CNC Router Technology: From 3-Axis to 5-Axis Systems

This article explores the advancements in CNC router technology, tracing the journey from 3-axis machines to today's cutting-edge 5-axis systems and comparing their application differences.

Read More

Avoiding Deformation and Melting During Plastic CNC Routing

In this article, we will explore the factors contributing to deformation and melting during plastic CNC routing, providing insights into the causes and offering practical solutions to mitigate these risks.

Read More

How Thick of Wood Can a CNC Router Cut?

In this article, we'll examine how different specifications and techniques influence the thickness of wood that can be cut, providing you with insights to make the most of your CNC ...

Read More

Maximizing Your CNC Router Performance: Tips and Tricks for Beginners

In this article, we'll guide you through essential tips and share advanced strategies to improve efficiency and avoid mistakes, helping you get the most out of your CNC router.

Read More

Frequently Asked Questions

What Are 2040 CNC Routers Used For?

2040 CNC routers are versatile machines used in a wide range of industries for precise cutting, engraving, and shaping tasks. Their large working area (2000mm x 4000mm) makes them ideal for crafting oversized components or handling bulk production efficiently. They are widely utilized in woodworking to create furniture, cabinetry, and intricate decorative designs. In the plastics fabrication industries, they are employed for cutting, engraving, and prototyping durable parts. Additionally, they play a key role in signage production, enabling precise lettering, logos, and 3D carvings. Their adaptability also extends to composites, allowing for the production of molds, panels, and other industrial components with high accuracy.

What Types of 2040 CNC Routers Are There?

2040 CNC routers come in various types, each tailored to specific applications and levels of complexity. Here’s an overview:

- 3-Axis CNC Router: The most common type, designed for straightforward cutting and engraving tasks along the X, Y, and Z axes. Ideal for flat material work like signage, furniture, and panels.

- ATC (Automatic Tool Changer) CNC Router: Equipped with an automatic tool-changing system, this CNC router streamlines workflow by swapping tools during operations, perfect for projects requiring multiple tool types.

- 4-Axis CNC Router: Adds rotation to the cutting head, allowing work on angled surfaces and more intricate designs like cylindrical carvings.

- 4-Axis ATC CNC Router: Combines the functionality of a 4-axis machine with an automatic tool changer, enhancing efficiency for complex and detailed projects.

- 5-Axis CNC Router: Offers full freedom of movement across five axes, enabling cutting, carving, and shaping of highly complex 3D objects.

- Rotary Axis CNC Router: Features a rotary attachment for cylindrical material, ideal for creating columns, table legs, and other round components.

How Much are 2040 CNC Routers?

The cost of 2040 CNC routers varies based on their features and capabilities. Here are approximate price ranges for different types:

- 3-Axis CNC Router: Suitable for basic cutting and engraving tasks, these machines typically range from $3,000 to $6,500.

- ATC (Automatic Tool Changer) CNC Router: Equipped with automatic tool-changing capabilities, prices generally fall between $6,000 and $20,000, depending on specifications.

- 4-Axis CNC Router: These routers are designed for more complex operations involving additional rotational movement, costing around $10,000 to $18,000.

- 4-Axis ATC CNC Router: Combining four-axis functionality with an automatic tool changer, these machines typically cost between $19,000 and $25,000.

- 5-Axis CNC Router: Offering advanced capabilities for intricate and multidimensional tasks, prices usually range from $55,000 to $70,000.

- Rotary Axis CNC Router: These routers are generally priced between $5,000 and $15,000, featuring a rotary axis for cylindrical workpieces.

How Precise Are 2040 CNC Routers?

2040 CNC routers are engineered for exceptional precision, making them a reliable choice for intricate and high-quality machining. Their accuracy typically ranges between 0.01mm to 0.1mm, depending on the machine’s build, motion control system, and calibration. Key features contributing to their precision include ball screw drives, linear guide rails, and advanced motion control systems that minimize errors and vibrations.

For applications like fine engraving, detailed 3D carving, and complex prototyping, 2040 CNC routers deliver consistent and repeatable results. Regular maintenance, proper setup, and high-quality tooling further enhance their performance, ensuring that even the most demanding tasks are executed with unparalleled accuracy.

Do 2040 CNC Routers Support Adding Accessories?

Yes, 2040 CNC routers are highly versatile and support a wide range of accessories to enhance functionality and adapt to specific applications. Commonly supported add-ons include:

- Rotating Axis: Ideal for working on cylindrical materials, such as table legs or columns, enabling precise 360° carving.

- 360° Rotating Cutting Saw: Perfect for cutting materials at various angles, offering flexibility for advanced woodworking or fabrication tasks.

- Drilling Unit: Speeds up multi-hole drilling for panel production or cabinetry, improving efficiency in high-volume projects.

- Oscillation Knife Head: Ideal for cutting soft materials like foam, rubber, and leather with precision and minimal material distortion.

- Plasma Cutting Head: Adds metal-cutting capabilities, making the router suitable for fabricating steel, aluminum, and other metals.

- Auto Loading & Unloading Device: Automates material handling, reducing labor and streamlining large-scale production workflows.

Can the Working Height of 2040 CNC Routers Be Customized?

Yes, the working height of 2040 CNC routers can typically be customized to meet specific project and material requirements. AccTek CNCs will flexibly adjust the Z-axis clearance to accommodate thicker materials or special applications, such as machining foams, composite blocks, or tall workpieces.

Customizable working heights are especially beneficial for industries like woodworking, where varying material thicknesses are common, or for tasks requiring deeper cuts or 3D carving. When customizing the working height, it’s important to ensure the CNC router’s spindle power, tooling, and structural stability are compatible with the increased range to maintain precision and performance.

What Customer Support Do 2040 CNC Routers Provide?

2040 CNC routers come with reliable customer support options to ensure smooth operation and user satisfaction:

- Free Online Technical Support: Customers can access complimentary technical assistance through online platforms, including email, chat, or video support. This service is ideal for troubleshooting, software setup, or resolving operational issues remotely.

- Paid On-Site Training: For users requiring hands-on guidance, on-site training sessions are available at an additional cost. These sessions cover installation, operation, and maintenance to ensure optimal use of the machine.

What Is The Warranty Period of 2040 CNC Routers?

Our CNC router is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

- 3-Year Warranty for the Entire Machine: This full warranty covers any defects or malfunctions in the machine as a whole, ensuring reliable performance and longevity over time.

- 5-Year Warranty for Core Components: Key components essential for optimal machine operation are covered for 1.5 years. This includes parts that may experience wear and tear with regular use, ensuring you have support for the most vital parts of the machine.