MDF CNC Router

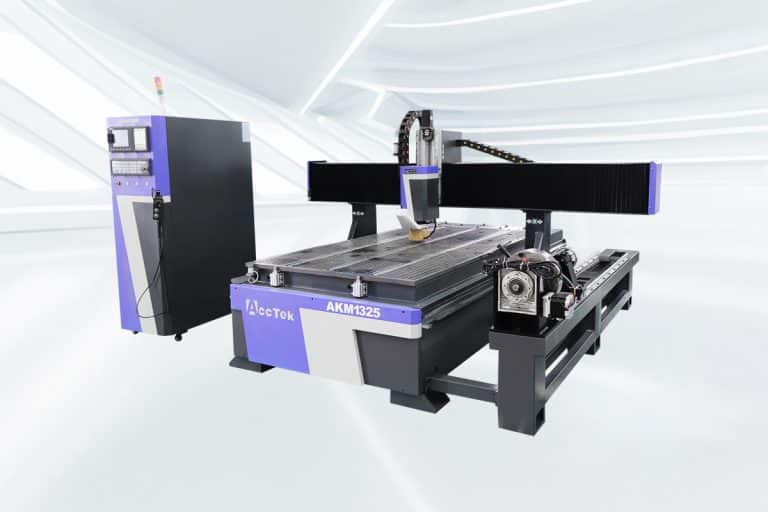

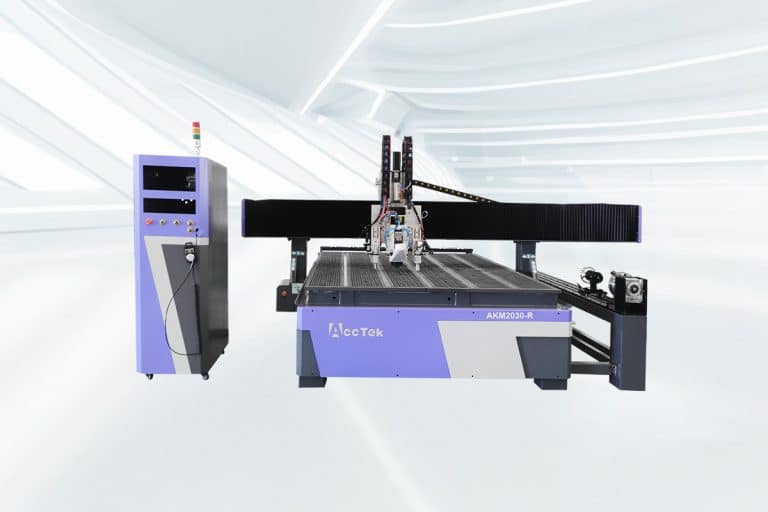

MDF (Medium Density Fiberboard) CNC routers are powerful, precise, and versatile tools designed to meet the needs of industries requiring high-quality, detailed cutting and engraving. Ideal for woodworking, cabinetry, sign-making, and furniture production, these machines provide a reliable solution for professionals looking to streamline their production processes. Built with advanced CNC (Computer Numerical Control) technology, MDF CNC routers offer exceptional accuracy, speed, and repeatability. Whether you’re shaping intricate patterns, carving detailed designs, or cutting large panels, these CNC routers are engineered to handle a wide range of materials, especially MDF, ensuring smooth edges and flawless finishes every time.

Our range of MDF CNC routers caters to businesses of all sizes, from small workshops to large-scale manufacturing operations. With customizable features such as automatic tool changers, rotary axes, and robust spindles, these machines can be tailored to fit your unique production requirements. Furthermore, their user-friendly interface and integration with CAD/CAM software make them easy to operate, reducing the learning curve for your team and increasing productivity. Investing in an MDF CNC router is an investment in quality, efficiency, and long-term reliability. Whether you’re looking to scale production, improve precision, or reduce material waste, these CNC routers provide the perfect solution for modern woodworking and manufacturing needs.

Tips for Choosing the Right MDF CNC Router

Selecting the right MDF CNC router is crucial to achieving precision, efficiency, and reliability in your woodworking or manufacturing projects. With a variety of models, features, and configurations available, it can be overwhelming to make the best choice.

Assess Your Production Needs

Before purchasing an MDF CNC router, evaluate the scale of your operations. For high-volume production, you’ll need a CNC router with a high-speed spindle and automation features. For small-scale workshops, a more basic machine may suffice. Understanding your production requirements will help narrow down your options.

Consider the Router’s Cutting Area

The cutting area of a CNC router determines the size of the material it can process. Measure the size of your standard workpieces and ensure the machine can accommodate them. Larger cutting areas allow for versatility in handling a variety of MDF sizes and shapes.

Check the Spindle Power and Speed

The spindle is the heart of any CNC router. Choose a machine with sufficient spindle power (usually measured in horsepower) to handle dense MDF materials. A higher speed is also important for faster, more efficient cutting without compromising on quality.

Look for Precision and Accuracy

Accuracy is key when working with MDF, especially for detailed cutting or engraving. Ensure the CNC router has a high-resolution motion control system that guarantees precise cuts and maintains tight tolerances for intricate designs and patterns.

Evaluate the Build Quality and Stability

A stable, well-built frame is essential for minimizing vibrations during operation, which can negatively affect cutting quality. Look for machines with a robust and rigid frame, usually made of heavy-duty steel or aluminum, for maximum stability.

Opt for a Reliable Controller System

The controller system is crucial for seamless integration with CAD/CAM software and for achieving consistent results. A reliable, easy-to-use controller will simplify the programming and operation of the CNC router, leading to better efficiency and fewer errors.

Determine the Type of Drive System

CNC routers use various drive systems, including rack-and-pinion, ball screws, and linear guides. Ball screws offer higher precision and are ideal for detailed work, while rack-and-pinion systems may be better for larger-scale cutting due to their faster speeds.

Evaluate Dust Collection Systems

MDF cutting produces a lot of dust, which can interfere with machine performance and create a hazardous work environment. Ensure that the CNC router includes a powerful dust collection system or plan for an external system to maintain a clean and safe workspace.

Assess Maintenance Requirements

Some CNC routers require more frequent maintenance than others. Look for a model with low-maintenance components, or one that offers easy access for routine maintenance tasks. Machines that need less upkeep will save you time and reduce downtime in the long run.

Check for Optional Features

Many MDF CNC routers offer optional features, such as automatic tool changers (ATC) or rotary axes, that can increase versatility and efficiency. If you anticipate requiring these functions in your projects, it may be worth investing in a model that offers them.

Look for Warranty and Support

A good warranty and reliable customer support are essential for any machinery purchase. Check the terms of the warranty to ensure it covers key components and inquire about the availability of technical support in case of issues or malfunctions.

Consider Your Budget

While you may be tempted to purchase the most advanced machine, it’s important to balance features with your budget. Consider long-term costs, including maintenance, parts replacement, and any upgrades you may need, and ensure the CNC router you select fits within your financial capabilities.

What Materials Can The MDF CNC Router Cut

MDF CNC routers are highly versatile and can cut a wide range of materials beyond just MDF. These machines are capable of handling various types of wood, including hardwoods, softwoods, and plywood, making them ideal for cabinetry, furniture production, and woodworking projects. Additionally, they can cut composites, plastics, acrylics, and even certain metals like aluminum, depending on the machine’s specifications and spindle power. The precision and adaptability of MDF CNC routers ensure that they deliver clean, accurate cuts on different materials, making them an essential tool for diverse manufacturing applications. Whether you’re working with wood, plastic, or lightweight metals, an MDF CNC router can help streamline your production process.

- Standard MDF

- Moisture-Resistant MDF

- Fire-Rated MDF

- Ultra-Light MDF

- Veneered MDF

- High-Density MDF

Application Industry

Handicraft Industry

The application of CNC routers in the handicraft industry transcends tradition and opens new doors to creativity while retaining the essence of handcrafted excellence.

Plastic Fabrication Industry

The CNC router is capable of precision engraving, routing, and cutting of various types of plastics, allowing manufacturers to easily implement complex designs and meet strict specifications.

Musical Instrument Industry

The CNC router operates with unparalleled precision and efficiency, transforming raw materials into finely detailed components that give each instrument its unique character and sound.

Furniture Manufacturing

With its ability to cut, engrave, and shape materials with unparalleled precision, CNC routers have opened up a world of opportunities for designers and manufacturers in the furniture industry.

Blog

A Beginner’s Guide to 4-Axis CNC Routers with Swing Head

In this guide, we'll walk you through the basics of 4-axis CNC routers, from key components and initial setup to operational steps, common challenges, and maintenance tips, so you can ...

Read More

Can CNC Routers be Upgraded or Expanded?

In this article, we'll explore the types of upgrades available for your CNC router, the benefits they bring, and the considerations before modifying the CNC system to help you get ...

Read More

How Do I Set Up My CNC Router for the First Time?

This article provides a step-by-step guide to help you through your initial setup process—from unboxing and assembling the machine to installing software, calibrating axes, and running your first test job.

Read More

How Does a Rotary Axis CNC Router Differ From a 4-Axis CNC Router?

This article explores how these rotary axis CNC routers and 4-axis CNC routers differ in structure, functionality, and application, helping you decide which is best suited for your production needs.

Read More

Frequently Asked Questions

How Do MDF CNC Routers Work?

MDF CNC routers operate using computer-controlled systems to automate the cutting, engraving, and shaping of materials with precision. The process begins with designing a 2D or 3D model of the part or pattern in CAD (Computer-Aided Design) software. This design is then converted into machine-readable code using CAM (Computer-Aided Manufacturing) software.

Once the code is ready, it is uploaded to the CNC router’s controller. The CNC router reads this code and uses its motors to move the cutting head and material along pre-programmed paths. The CNC router’s spindle, which holds the cutting tool, rotates at high speeds to precisely carve through materials like MDF, wood, or plastics.

The entire process is automated, allowing for high-speed, repeatable, and intricate cuts without the need for manual intervention. This ensures consistent quality and enhances productivity in both small and large-scale manufacturing environments.

What is the Cutting Speed of MDF CNC Routers?

The cutting speed of MDF CNC routers depends on several factors, including spindle speed, feed rate, material thickness, and the complexity of the cut. Typically, cutting speeds range from a few inches per minute for intricate cuts to several hundred inches per minute for rough cuts. The spindle speed, which determines the rotation speed of the cutting tool, plays a critical role in determining how fast the CNC router can cut through MDF.

While higher speeds can increase production efficiency, it’s important to balance cutting speed with cut quality. Too high a speed may impact precision and the finish of the cut. The optimal cutting speed for MDF will vary based on the thickness of the material, the cutting tool used, and the desired finish. For the best results, operators often adjust settings based on specific project requirements, referring to machine manuals and specifications to fine-tune speeds for optimal performance.

What Router Bit is on the MDF CNC Router?

The choice of router bit for MDF CNC routers depends on the cutting task and desired finish. Common types include:

- Spoilboard Cutter: Used to level the spoil board for even surface preparation.

- Straight Router Bits: Ideal for general cuts, edge profiling, and grooving.

- Spiral Upcut Router Bits: Effective for clean cuts and chip evacuation, especially for plunge cutting.

- Compression Bits: Combines upcut and downcut edges to prevent chip-out, perfect for through cuts.

- Downcut Router Bits: Minimizes splintering on the top surface, ensuring a clean finish.

- Ball Nose Router Bits: Used for 3D contouring and carving, creating smooth, intricate designs.

- V-Router Bits: Ideal for engraving and creating precise angles or V-grooves.

What is the Best MDF for Routing?

CNC routers can cut various types of MDF, each suited for different applications. The best type of MDF for routing depends on your specific needs and project requirements:

- Standard MDF: The most common type, ideal for a wide range of woodworking projects.

- Moisture-Resistant MDF: Perfect for humid environments like kitchens and bathrooms, offering better durability against moisture.

- Fire-Rated MDF: Designed to meet fire safety standards, making it suitable for applications requiring fire resistance.

- Ultralight MDF: Easier to work with and less dense, ideal for lightweight projects where weight is a concern.

- Veneer MDF: Features a wood veneer surface, offering an elegant finish, and can be shaped using CNC routers for intricate designs.

- High-Density MDF: Requires more powerful CNC routers but is suitable for robust applications that demand additional strength and durability.

How Much Do MDF CNC Routers Cost?

The cost of MDF CNC routers varies significantly depending on factors like machine size, features, brand, and capabilities. On average, entry-level models can cost between $3,000 and $10,000, making them suitable for small workshops or hobbyists. Mid-range CNC routers, with higher precision, larger work areas, and more advanced features, typically range from $10,000 to $30,000. High-end industrial-grade models, designed for large-scale production, can cost $30,000 or more, offering enhanced power, speed, and automation.

Additional costs may include installation, maintenance, software, and accessories such as CNC router bits and dust collection systems. When selecting a CNC router, it’s important to consider your specific needs and budget to find a model that balances affordability with the features required for your projects.

How to Safely Operate MDF CNC Routers?

Operating an MDF CNC router requires attention to safety to protect both the operator and the equipment. Follow these essential guidelines to ensure safe and effective operation:

- Wear Protective Gear: Always wear safety glasses, hearing protection, and dust masks to protect against debris, noise, and harmful dust generated during cutting.

- Inspect the Machine Before Use: Check the CNC router for any loose parts, damaged cables, or potential issues. Ensure that all safety covers and guards are in place before starting the machine.

- Proper Setup of Material: Secure the MDF properly on the machine bed to prevent shifting during cutting. Use clamps or a vacuum table to ensure a stable workpiece.

- Use the Right Router Bit: Select the correct router bit for your specific job. Using the wrong bit can result in poor cuts or even damage to the machine.

- Maintain a Clean Workspace: Keep the work area clean and free of obstacles. Ensure that dust collection systems are in good working condition to minimize the risk of fire and maintain air quality.

- Avoid Loose Clothing and Jewelry: Loose clothing or jewelry can get caught in moving parts. Always tie back long hair and remove accessories before operating the CNC router.

- Monitor During Operation: Even though CNC routers are automated, it’s crucial to supervise the machine while it’s running to ensure it is performing correctly and safely.

- Follow the Manufacturer’s Guidelines: Always refer to the machine’s manual for specific operating instructions, maintenance schedules, and safety protocols.

- Regular Maintenance: Perform routine maintenance to keep the CNC router in optimal working condition. This includes lubricating moving parts, checking for wear, and cleaning components.

What Customer Support Do MDF CNC Routers Provide?

MDF CNC routers come with reliable customer support options to ensure smooth operation and user satisfaction:

- Free Online Technical Support: Customers can access complimentary technical assistance through online platforms, including email, chat, or video support. This service is ideal for troubleshooting, software setup, or resolving operational issues remotely.

- Paid On-Site Training: For users requiring hands-on guidance, on-site training sessions are available at an additional cost. These sessions cover installation, operation, and maintenance to ensure optimal use of the machine.

What Is The Warranty Period of MDF CNC Routers?

Our CNC router is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

- 3-Year Warranty for the Entire Machine: This full warranty covers any defects or malfunctions in the machine as a whole, ensuring reliable performance and longevity over time.

- 5-Year Warranty for Core Components: Key components essential for optimal machine operation are covered for 1.5 years. This includes parts that may experience wear and tear with regular use, ensuring you have support for the most vital parts of the machine.