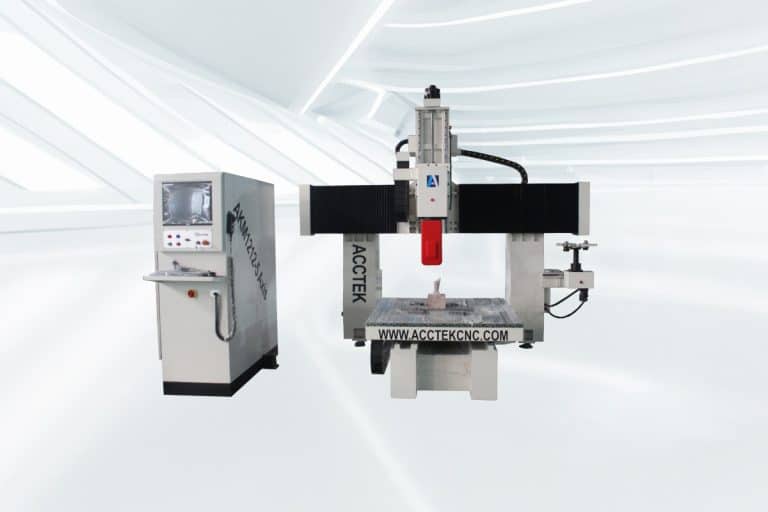

1212 CNC Router

The 1212 CNC router is the perfect solution for businesses and individuals seeking precision, versatility, and efficiency in their machining processes. With a working area of 1200 x 1200 mm, this compact yet powerful machine is designed to handle a variety of materials, including wood, acrylic, plastics, aluminum, and more, making it ideal for industries such as woodworking, signage, prototyping, and custom manufacturing. Engineered for high performance, the 1212 CNC router features a robust frame, advanced motion control systems, and a high-speed spindle, ensuring precise and consistent results even on complex designs. Its intuitive control system, coupled with compatibility with leading CAD/CAM software, makes it user-friendly for beginners while offering advanced capabilities for seasoned professionals.

Built to last, the 1212 CNC router is constructed with premium components for durability and stability, ensuring long-term reliability and minimal maintenance. Its compact footprint allows it to fit seamlessly into workshops of all sizes without sacrificing functionality or performance. Whether you’re producing intricate carvings, detailed engravings, or custom parts, the 1212 CNC router provides the accuracy and efficiency you need to take your projects to the next level. Invest in the 1212 CNC router to unlock endless possibilities and achieve professional-grade results with ease and confidence.

Tips for Choosing the Right 1212 CNC Router

Choosing the right CNC router is crucial for achieving precise, efficient, and high-quality results in your machining projects. Whether you’re a hobbyist, small business owner, or industrial user, understanding key factors will help you make an informed decision.

Identify Your Primary Applications

Determine the types of projects you’ll handle most frequently. Whether it’s intricate engraving, furniture making, or sign cutting, ensure the CNC router supports your intended materials and project scope. The 1212 CNC router is versatile enough for woodworking, plastics, and light metals, making it ideal for diverse applications.

Consider the Work Area Dimensions

Evaluate the size of the cutting area for your project requirements. The 1212 CNC router, with its 1200 x 1200 mm workspace, is perfect for small to medium-sized jobs, offering ample room without consuming too much workshop space. Always ensure the router can accommodate your material dimensions comfortably.

Assess the Machine’s Precision

High precision is critical for detailed designs and complex cuts. Look for routers with reliable motion systems and minimal runout. The 1212 CNC router offers exceptional accuracy and repeatability, ensuring flawless results, even on intricate projects, whether you’re engraving fine details or cutting sharp corners.

Check Frame and Build Quality

A rigid and well-constructed frame reduces vibrations and enhances cutting accuracy. CNC routers with aluminum or steel frames, like the 1212 CNC router, offer stability and durability. Solid construction ensures consistent performance over time and is essential for professional-grade results.

Evaluate Spindle Power and Speed

Choose a spindle with enough power to handle your materials efficiently. A high-power spindle is essential for cutting dense materials like aluminum, while a mid-range spindle suits lighter materials. The 1212 CNC router strikes a balance, offering flexibility for a variety of materials and project needs.

Ensure Software Compatibility

Select a router that works with leading CAD/CAM software to simplify design and production workflows. Compatibility with intuitive software ensures that both beginners and advanced users can create and execute designs effortlessly. Look for machines that offer smooth integration with your existing tools.

Review Speed and Productivity

Cutting and travel speeds directly impact productivity. High-speed routers like the 1212 CNC router allow for faster processing without compromising precision. Evaluate your project volumes and choose a router that can handle tight deadlines while maintaining consistent quality.

Prioritize Dust Management Systems

For woodworking or other tasks that generate debris, an efficient dust collection system is crucial. The 1212 CNC router can be paired with a dust extraction setup to keep your workspace clean, protect sensitive components, and improve visibility during operation.

Look for User-Friendly Features

Ease of use is essential, especially for new operators. A router with an intuitive interface, clear instructions, and a supportive user community ensures a smooth learning curve. The 1212 CNC router is designed to accommodate both beginners and professionals with minimal hassle.

Check Tool Compatibility and Expandability

Invest in a CNC router that supports various tool attachments, such as rotary axes, vacuum tables, or auto tool changers. These options enhance the CNC router’s versatility and allow you to tackle a broader range of projects, ensuring your investment remains valuable as your needs grow.

Consider Maintenance and Support

A low-maintenance router with readily available parts and reliable customer support is essential for reducing downtime. The 1212 CNC router is built for durability and ease of upkeep, ensuring consistent performance with minimal interruptions over its lifespan.

Balance Performance and Budget

Determine your budget and compare available options to find the best value. The 1212 CNC router offers an excellent balance of affordability, reliability, and advanced features, making it an excellent choice for businesses and hobbyists seeking professional results.

What Materials Can the 1212 CNC Router Cut?

The 1212 CNC router is a versatile machine capable of cutting, engraving, and shaping a wide range of materials with precision and efficiency. Designed to handle both soft and hard materials, it can process wood, plastics, acrylics, soft metals like aluminum, and composite materials with ease. Its powerful spindle and precise motion control system make it suitable for intricate designs and heavy-duty tasks alike.

This CNC router is ideal for applications in industries such as woodworking, signage, prototyping, and custom fabrication. Whether you’re creating detailed carvings, cutting durable parts, or engraving fine patterns, the 1212 CNC router ensures smooth and accurate results. Its ability to adapt to diverse materials makes it a reliable tool for hobbyists, small businesses, and professionals seeking high-quality outputs across various projects.

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

Advancements in CNC Router Technology: From 3-Axis to 5-Axis Systems

This article explores the advancements in CNC router technology, tracing the journey from 3-axis machines to today's cutting-edge 5-axis systems and comparing their application differences.

Read More

Avoiding Deformation and Melting During Plastic CNC Routing

In this article, we will explore the factors contributing to deformation and melting during plastic CNC routing, providing insights into the causes and offering practical solutions to mitigate these risks.

Read More

How Thick of Wood Can a CNC Router Cut?

In this article, we'll examine how different specifications and techniques influence the thickness of wood that can be cut, providing you with insights to make the most of your CNC ...

Read More

Maximizing Your CNC Router Performance: Tips and Tricks for Beginners

In this article, we'll guide you through essential tips and share advanced strategies to improve efficiency and avoid mistakes, helping you get the most out of your CNC router.

Read More

Frequently Asked Questions

How Much Are 1212 CNC Routers?

The cost of 1212 CNC routers depends on their features and capabilities, catering to a range of user needs:

- Hobby 3-Axis CNC Router: Ideal for beginners or small-scale projects, these models typically cost between $3,500 and $4,500, offering affordability without sacrificing essential functionality.

- Hobby ATC CNC Router: For users seeking efficiency and automation, the addition of an automatic tool changer (ATC) raises the price from $7,000 to $7,500, making it a great option for advanced hobbyists or small businesses.

- 5-Axis ATC CNC Router: Designed for professional and industrial use, these high-performance machines handle complex, multi-dimensional projects and are priced between $56,000 and $58,000, reflecting their superior versatility and precision.

What is the Spindle Power of 1212 CNC Routers?

The spindle power of 1212 CNC routers varies depending on the type of machine and its intended use:

- Hobby 3-Axis CNC Router: Equipped with a 1.5 kW spindle, this model is suitable for light to moderate cutting tasks, making it perfect for hobbyists and small-scale projects.

- Hobby ATC CNC Router: Featuring a 2.2 kW spindle, this machine offers enhanced cutting power and efficiency, ideal for advanced users or small businesses handling a wider range of materials.

- 5-Axis ATC CNC Router: With a powerful 10 kW spindle, this industrial-grade machine can handle demanding, multi-dimensional cutting and milling tasks, ensuring exceptional performance for professional applications.

How Precise Are 1212 CNC Routers?

The precision of 1212 CNC routers depends on their build quality, motion control systems, and spindle capabilities, but generally, they offer excellent accuracy suitable for detailed work:

- Hobby 3-Axis CNC Routers: These machines typically achieve a precision of ±0.05 mm, making them ideal for small-scale projects where moderate accuracy is required.

- Hobby ATC CNC Routers: With enhanced components and automation, these routers can reach a precision of ±0.03 mm, ensuring more consistent results for complex or repetitive tasks.

- 5-Axis ATC CNC Routers: Designed for professional and industrial applications, these routers provide precision of ±0.01 mm or better, enabling them to handle intricate designs and multi-dimensional projects with extreme accuracy.

Can 1212 CNC Routers Handle 3D Engraving?

The ability of 1212 CNC routers to handle 3D engraving depends on the specific model:

- Hobby 3-Axis CNC Routers: No, these machines are not capable of true 3D engraving. They are limited to 2.5D work, such as shallow reliefs or layered designs, but cannot achieve full 3D carving.

- Hobby ATC CNC Routers: No, while these routers feature automatic tool changing for improved efficiency, they are still limited to 2.5D operations and cannot perform complex 3D engraving.

- 5-Axis ATC CNC Routers: Yes, these advanced machines are fully capable of handling intricate 3D engraving. With simultaneous movement across five axes, they excel in multi-dimensional designs, making them the ideal choice for professional-grade 3D carving.

Do 1212 CNC Routers Support Adding Accessories?

Yes, 1212 CNC routers support adding a variety of accessories, enabling users to expand their machine’s functionality. Common accessories include:

- Rotary Axes: For machining cylindrical objects like furniture legs or columns.

- Vacuum Tables: For secure workpiece holding during cutting.

- Dust Collection Systems: To maintain a clean workspace and protect components.

- Mist Coolant Systems: For cooling during metal cutting.

- Toolset Upgrades: Such as larger spindles or automatic tool changers (ATC).

How to Maintain 1212 CNC Routers?

Proper maintenance ensures the longevity and consistent performance of your 1212 CNC router. Follow these key steps:

- Clean the Machine Regularly: Remove dust, debris, and leftover material from the cutting area, rails, and spindle after each use to prevent buildup and wear.

- Lubricate Moving Parts: Apply lubricant to linear guides, ball screws, and other moving components periodically to reduce friction and ensure smooth motion.

- Inspect Electrical Connections: Check cables, plugs, and connections for damage or wear, ensuring everything is securely connected to avoid operational issues.

- Check the Spindle: Regularly inspect the spindle for signs of wear or overheating. Replace bearings or parts if necessary to maintain cutting precision.

- Test Tool Holders: Ensure tool holders are clean, free of debris, and securely fastened to avoid damage or poor performance during operation.

- Tighten Screws and Bolts: Periodically inspect and tighten screws and bolts to prevent looseness caused by vibrations during cutting.

- Monitor Software and Firmware: Keep your CNC software and machine firmware up to date to take advantage of bug fixes and improved features.

- Inspect the Cooling or Dust Collection System: Ensure that cooling systems are functioning correctly and that dust collection hoses and filters are clear.

- Replace Worn Components: Proactively replace consumables such as cutting tools, belts, or brushes to maintain efficiency and accuracy.

- Schedule Professional Servicing: For complex maintenance tasks or thorough inspections, schedule professional servicing to prevent unexpected downtime.

What Customer Support Do 1212 CNC Routers Provide?

1212 CNC routers come with reliable customer support options to ensure smooth operation and user satisfaction:

- Free Online Technical Support: Customers can access complimentary technical assistance through online platforms, including email, chat, or video support. This service is ideal for troubleshooting, software setup, or resolving operational issues remotely.

- Paid On-Site Training: For users requiring hands-on guidance, on-site training sessions are available at an additional cost. These sessions cover installation, operation, and maintenance to ensure optimal use of the machine.

What Is The Warranty Period of 1212 CNC Routers?

Our CNC router is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

- 3-Year Warranty for the Entire Machine: This full warranty covers any defects or malfunctions in the machine as a whole, ensuring reliable performance and longevity over time.

- 5-Year Warranty for Core Components: Key components essential for optimal machine operation are covered for 1.5 years. This includes parts that may experience wear and tear with regular use, ensuring you have support for the most vital parts of the machine.