4-Axis CNC Router

The 4-axis CNC router is a versatile machining tool designed to take your production capabilities to the next level. By adding a swing axis that allows the spindle to swing ±90°, this machine offers enhanced flexibility for simple 3D machining, making it ideal for more complex designs and precise, multi-dimensional cuts that standard 3-axis systems can’t achieve. Perfect for industries such as woodworking, plastics, and composites, the 4-axis CNC router can perform a variety of tasks including engraving, milling, drilling, and contouring. The added swing axis allows for the creation of intricate curves, angles, and cylindrical shapes with exceptional accuracy. This makes it especially useful for applications like custom part fabrication, 3D modeling, signage, and furniture production.

With its ability to handle simple 3D machining, the 4-axis CNC router provides the flexibility to work on more detailed and creative designs, while improving productivity and reducing the risk of errors. Whether you’re working with standard materials or complex geometries, this machine offers reliability, efficiency, and ease of use, making it a valuable addition to both small shops and large manufacturing operations. Unlock new possibilities in your production process with our 4-axis CNC router—designed for precision, versatility, and efficiency in 3D machining.

-

AKM1530-R CNC Router

Rated 5.00 out of 5$6,100.00 Add to cart -

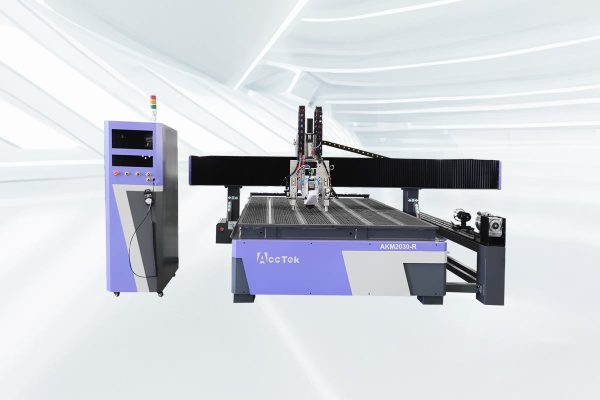

AKM2030-R CNC Router

Rated 5.00 out of 5$6,700.00 Add to cart -

AKM2040-R CNC Router

Rated 5.00 out of 5$7,200.00 Add to cart -

AKM1325-4R CNC Router

Rated 5.00 out of 5$8,500.00 Add to cart -

AKM1530-4R CNC Router

Rated 5.00 out of 5$9,600.00 Add to cart -

AKM2030-4R CNC Router

Rated 5.00 out of 5$10,200.00 Add to cart -

AKM2040-4R CNC Router

Rated 5.00 out of 5$10,600.00 Add to cart

Tips for Choosing the Right 4-Axis CNC Router

Choosing the right 4-axis CNC router is an important decision that can significantly impact your business’s productivity, precision, and efficiency. With so many options available, it’s essential to understand the key factors that influence machine performance. From the type of materials you work with to the machine’s capabilities and maintenance requirements, making an informed choice ensures that the CNC router meets both your short-term needs and long-term goals.

Determine Your Specific Needs

Identify the type of projects you’ll be working on. Do you need to create intricate 3D designs, or is your focus on simpler tasks like engraving? Understanding your project’s requirements will help you select a CNC router that matches your needs, ensuring efficiency and minimizing unnecessary features that could increase costs.

Evaluate the Work Area Size

The bed size of the CNC router is critical in determining the size of materials you can handle. Ensure the CNC router’s work area is large enough to accommodate your typical projects, but avoid selecting an oversized machine that will take up unnecessary space or increase costs without adding value.

Assess Spindle Power

The spindle power affects the CNC router’s ability to cut through various materials. For harder materials like metals, a higher spindle power is essential for efficient and precise cutting. For softer materials like wood or plastic, lower spindle power may suffice. Choose a CNC router with the right spindle power based on your material requirements.

Understand the Swing Axis Range

The primary feature of a 4-axis CNC router is the added swing axis, allowing the spindle to swing ±90°. This feature is crucial for achieving multi-dimensional cuts and 3D machining. Ensure the CNC router offers the necessary swing range to handle your specific project requirements for more detailed and complex work.

Material Compatibility

Ensure the CNC router is compatible with the types of materials you plan to cut. Some CNC routers are optimized for wood, while others can handle metals, plastics, and composites. Make sure the machine’s design, spindle power, and cutting capabilities align with the material types you use most frequently.

Prioritize Precision and Accuracy

Precision is key to high-quality results. Look for a machine with tight tolerances and reliable performance to ensure accurate cuts every time. A CNC router with better precision minimizes errors and helps you achieve the detailed designs required in industries such as aerospace, automotive, and custom part production.

Check Software Compatibility

The control software used by the CNC router plays a major role in its performance. Ensure that the CNC router is compatible with the CAD/CAM software you use. The more flexibility the machine has with various design programs, the easier it will be to integrate into your workflow and enhance productivity.

Consider Machine Speed

Speed is crucial for improving efficiency, especially in mass production. Evaluate the CNC router’s feed rate and spindle speed to ensure it can handle the pace required for your business needs. However, ensure the machine can balance speed with accuracy to avoid compromising the quality of more complex designs.

Evaluate Durability and Build Quality

A 4-axis CNC router should be built to last, especially if you plan to use it for high-volume production. Look for a machine made from durable materials and high-quality components. A well-built CNC router will be more reliable, require less maintenance, and provide consistent performance over time.

Check Maintenance Requirements

Maintenance plays a significant role in the longevity and performance of your CNC router. Before making a decision, assess how much time and effort will be required to maintain the machine. Choose a model that is easy to service, with readily available parts, and minimal downtime for maintenance tasks.

Review the Warranty and Support

A solid warranty and reliable customer support are essential to ensure peace of mind after purchasing a 4-axis CNC router. Review the warranty terms to understand what is covered and how long coverage lasts. Additionally, ensure the manufacturer provides strong customer support for troubleshooting and technical issues.

Factor in the Total Cost of Ownership

When selecting a 4-axis CNC router, consider not only the initial purchase price but also the total cost of ownership. This includes maintenance, power consumption, consumables, software licenses, and any potential upgrades. Calculate long-term costs to ensure the machine aligns with your budget and overall business strategy.

What materials can the 4-axis CNC router cut?

The 4-axis CNC router is a versatile machine capable of cutting a wide variety of materials with precision and ease. From soft woods and plastics to harder metals and composites, this CNC router can handle a broad spectrum of materials, making it suitable for multiple industries including woodworking, metalworking, automotive, and aerospace. The added swing axis enhances its ability to work with complex geometries, curved surfaces, and intricate 3D designs. Whether you’re crafting detailed parts, prototypes, or custom products, the 4-axis CNC router ensures clean, accurate cuts across diverse material types, providing exceptional flexibility for your projects.

Application Industry

Construction Industry

The integration of CNC routers into construction workflows has ushered in a new era characterized by meticulous detailing, rapid prototyping, and improved material utilization.

Aerospace Industry

The CNC router is widely used in aerospace engineering due to its unparalleled ability to carve complex designs, manufacture complex parts, and ensure tight tolerances.

Jewelry Industry

The CNC router revolutionize the way fine jewelry is designed and made by delivering unparalleled precision and efficiency and producing intricate designs with meticulous attention to detail.

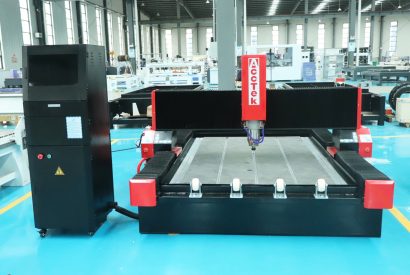

Stone Carving Industry

The integration of CNC routers into the stone carving industry is not only revolutionizing the way craftsmen carve, it is also redefining the boundaries of artistic possibilities in this ancient practice.

Blog

What Power CNC Router Spindle Should I Choose?

In this article, we'll explore how spindle power works, what factors you should consider, and how to choose the right CNC router spindle power based on your materials and application ...

Read More

How to Choose the Right Stone CNC Router for Your Workshop?

This guide will walk you through the key factors to consider when choosing a stone CNC router, designed to help you invest wisely in a machine that delivers reliable performance ...

Read More

Best Budget CNC Router for Making Outdoor Signs?

In this guide, we'll break down the key features to look for, explore different models under a variety of price points, and help you choose the best budget CNC router ...

Read More

How to Maintain and Troubleshoot the ATC CNC Router?

This article will walk you through a practical maintenance procedure for your ATC CNC router and instruct you on how to diagnose and repair common problems that may arise.

Read More

Frequently Asked Questions

How Do 4-Axis CNC Routers Work?

A 4-axis CNC router operates by utilizing a combination of traditional 3-axis movements (X, Y, and Z) with an additional rotary axis, usually referred to as the “A” axis. This rotary axis allows the spindle to rotate around the material, typically by ±90°, enabling the machine to cut or engrave on multiple sides of a workpiece without requiring it to be repositioned manually.

The process begins with the creation of a digital design using CAD/CAM software, which is then transferred to the router. The CNC router follows programmed instructions to move the cutting tool along the X, Y, and Z axes. Simultaneously, the rotary axis turns the workpiece for more complex cuts or 3D shapes. This capability allows for detailed and precise machining of cylindrical parts, curved surfaces, and intricate designs that would be difficult or impossible to achieve with a standard 3-axis CNC router.

By automating the cutting process on multiple sides of the material, a 4-axis CNC router increases efficiency, reduces the risk of errors, and allows for more complex and creative manufacturing solutions.

What Are 4-Axis CNC Routers Used For?

4-axis CNC routers are highly versatile machines used in various industries for complex and precise machining tasks. The addition of a swing axis allows these CNC routers to handle multi-dimensional cuts and intricate 3D designs, making them ideal for applications that require detailed and precise work. Here are some of the key uses:

- Custom Parts and Prototypes: 4-axis CNC routers are widely used in the production of custom parts, prototypes, and small-batch manufacturing. The rotary axis allows for machining on multiple surfaces without manual repositioning, making it perfect for creating unique designs and complex geometries.

- 3D Engraving and Carving: They are excellent for 3D engraving and carving on materials like wood, and plastics, enabling the creation of detailed sculptures, signs, and decorative elements.

- Automotive and Aerospace Components: 4-axis CNC routers are used in the automotive and aerospace industries to machine complex components, such as brackets, molds, and custom parts, requiring high precision and multi-sided machining.

- Signage and Furniture Production: For businesses involved in creating signage or custom furniture, these CNC routers are used to craft intricate designs, logos, and custom woodwork with smooth, accurate finishes.

- Tooling and Jigs: In manufacturing, 4-axis CNC routers can create custom tooling and jigs, enhancing precision in assembly and production lines.

How Much Are 4-Axis CNC Routers?

The price of a 4-axis CNC router can vary significantly depending on its features, size, and functionality. Generally, standard 4-axis CNC routers fall within the price range of $11,000 to $20,000. These machines typically offer solid performance for most applications, including 3D machining and multi-dimensional cuts, making them suitable for a variety of industries like woodworking, prototyping, and light metalworking.

For more advanced models equipped with an Automatic Tool Changer (ATC), prices range from $15,000 to $25,000. These machines offer enhanced efficiency, as the ATC allows for automatic switching between tools, reducing downtime during production. This feature is especially valuable in high-volume or complex machining projects where multiple tool changes are required.

Ultimately, the price will depend on the machine’s specifications, such as spindle power, bed size, software compatibility, and additional features like dust collection systems or custom tooling. It’s important to assess your specific needs and budget before making a decision.

What is the Spindle Power of 4-Axis CNC Routers?

The spindle power of a 4-axis CNC router plays a crucial role in determining the machine’s cutting capabilities, especially when working with tough materials. Standard 4-axis CNC routers typically come with a 6KW spindle, which is sufficient for most wood, plastic, and light metal cutting tasks. This power level provides a good balance between performance and energy efficiency for general applications, including 3D carving and engraving.

On the other hand, 4-axis ATC CNC routers are equipped with a more powerful 9KW spindle. The additional spindle power makes these routers better suited for more demanding applications, such as cutting harder materials like aluminum, stainless steel, or dense composites. The higher power also improves efficiency, allowing for faster cutting speeds and reduced tool wear, especially in high-volume production settings where tool changes are automated.

Choosing the right spindle power depends on the materials you plan to cut and the complexity of your projects. Higher spindle power ensures smoother, faster cutting and greater versatility, particularly for heavy-duty applications.

How Precise Are 4-Axis CNC Routers?

4-axis CNC routers are known for their high precision and accuracy, making them ideal for applications that require intricate detailing and complex multi-dimensional cuts. The precision of these routers is typically measured in terms of their repeatability and tolerance. Most 4-axis CNC routers offer repeatability within 0.01 mm to 0.1 mm, depending on the machine’s quality and calibration. This level of precision ensures that the router can consistently produce high-quality parts, whether you’re working on simple shapes or highly detailed 3D designs.

The addition of the swing axis allows for multi-sided machining without repositioning the material, and this swing movement is also highly controlled, ensuring accurate cuts on curved surfaces. The accuracy of the spindle, tool, and swing axis working together enables 4-axis CNC routers to handle delicate jobs like engraving, custom molds, and complex part production with minimal error.

However, achieving the highest precision also depends on factors such as machine calibration, tooling quality, and the specific application. For industries like aerospace, automotive, and custom prototyping, the precision of a 4-axis CNC router is often sufficient to meet even the most demanding specifications.

Can 4-Axis CNC Routers Handle 3D Engraving?

Yes, 4-axis CNC routers are excellent for handling 3D engraving. The addition of the swing axis (usually the A-axis) allows the spindle to rotate and access multiple sides of the workpiece without manual repositioning, which is essential for complex 3D designs. This capability makes 4-axis CNC routers highly suitable for engraving intricate details, curved surfaces, and multi-dimensional shapes that a standard 3-axis CNC router would struggle to achieve.

The rotary motion, combined with the standard X, Y, and Z movements, enables precise carving and engraving on cylindrical objects or non-flat surfaces. This is especially useful in industries like signage, custom jewelry, decorative arts, and automotive or aerospace components, where detailed 3D engravings are often required.

Additionally, the ability to engrave on multiple angles and surfaces in a single setup reduces the need for re-clamping or rotating the workpiece manually, increasing both the precision and efficiency of the process. Thus, 4-axis CNC routers are a great choice for businesses that require detailed, high-quality 3D engravings.

What Customer Support Do 4-Axis CNC Routers Provide?

4-Axis CNC Routers come with reliable customer support options to ensure smooth operation and user satisfaction:

- Free Online Technical Support: Customers can access complimentary technical assistance through online platforms, including email, chat, or video support. This service is ideal for troubleshooting, software setup, or resolving operational issues remotely.

- Paid On-Site Training: For users requiring hands-on guidance, on-site training sessions are available at an additional cost. These sessions cover installation, operation, and maintenance to ensure optimal use of the machine.

What Is The Warranty Period of 4-Axis CNC Routers?

Our CNC router is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

- 3-Year Warranty for the Entire Machine: This full warranty covers any defects or malfunctions in the machine as a whole, ensuring reliable performance and longevity over time.

- 5-Year Warranty for Core Components: Key components essential for optimal machine operation are covered for 1.5 years. This includes parts that may experience wear and tear with regular use, ensuring you have support for the most vital parts of the machine.