Table of Contents

Water Cooling Spindle VS Air Cooling Spindle

- 8-13 Min Read

In the realm of CNC machining, the choice between water-cooling and air-cooling spindles is a critical decision that significantly impacts the performance, efficiency, and longevity of the machining process. Both cooling methods come with their own set of advantages and drawbacks, and understanding the intricacies of each can help you make the right choice. In this article, we will delve into the details of water-cooling and air-cooling spindles, exploring their mechanisms, advantages, disadvantages, and the applications where each excels.

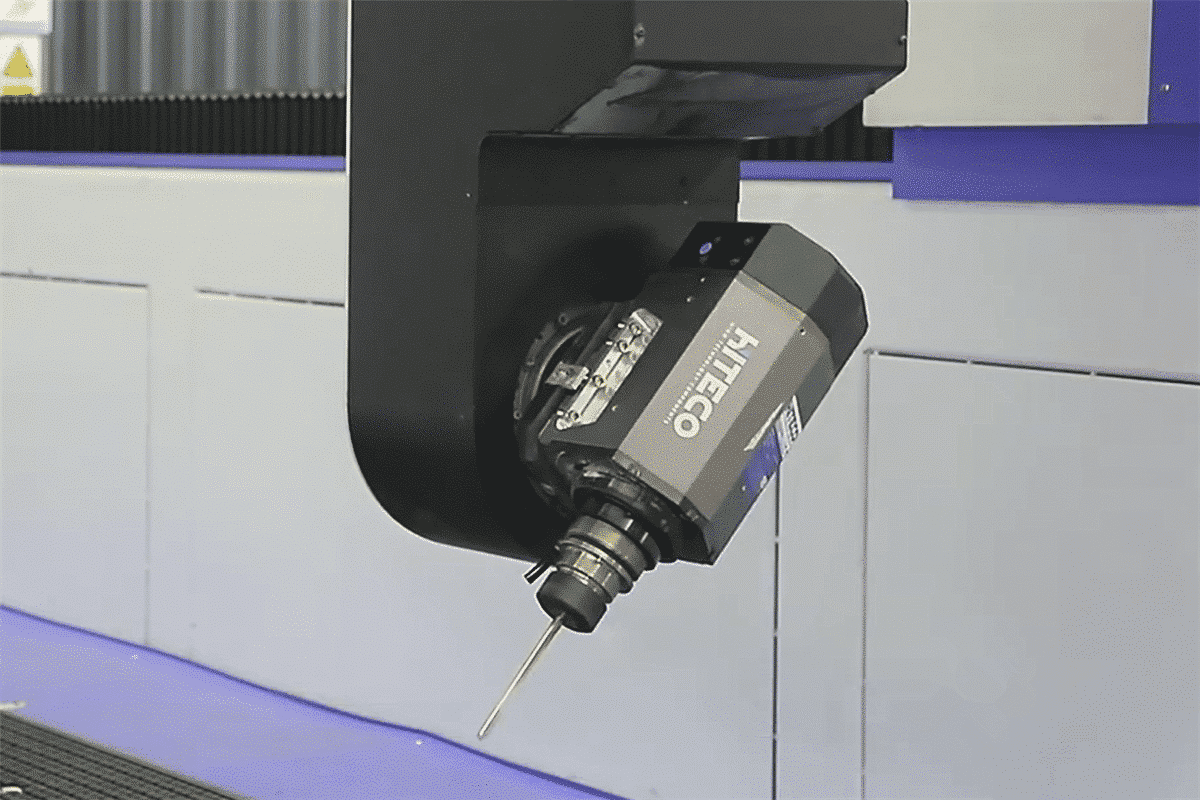

What is a spindle?

A spindle, in the context of machining and manufacturing, refers to a rotating component of a machine tool, often found in devices like lathes, CNC routers, and CNC (Computer Numerical Control) machines. The primary function of a spindle is to hold and rotate cutting tools or workpieces during machining operations. It facilitates the cutting, routing, or drilling processes by imparting motion to the tool based on the programmed instructions. Often referred to as the “heart” of a CNC machine, the spindle plays a pivotal role in transforming digital designs into tangible products. Here are its main functions:

- Rotational Motion: The spindle rotates at high speeds, providing the necessary motion to the cutting tool or workpiece. The rotational speed can be adjusted based on the requirements of the specific machining operation.

- Tool Holding: Spindles have a tool holder or a collet that securely grips the cutting tool. This ensures stability and precision during the machining process.

- Power Transmission: Spindles transmit power from the machine’s motor to the cutting tool. The amount of power, often measured in horsepower, influences the machine’s capability to handle various materials and perform different machining tasks.

The importance of cooling in spindle operation

Cooling is a critical aspect of spindle operation in machining, playing a pivotal role in maintaining optimal performance, and precision, and extending the lifespan of the equipment. The heat generated during machining processes, especially those involving high-speed rotations and heavy cutting loads, can have detrimental effects on the spindle and associated components. The importance of cooling in spindle operation can be understood through several key considerations:

Temperature Control

- Precision and Accuracy: Consistent temperature control helps maintain processing precision and accuracy. Heat can lead to thermal expansion and contraction, affecting the dimensions of the workpiece and the cutting tool. By keeping the spindle at a stable temperature, variations in machining dimensions can be minimized.

- Tool Life: Excessive heat can accelerate tool wear and reduce tool life. Cooling the spindle helps dissipate heat generated during cutting, contributing to the longevity of cutting tools and reducing the frequency of tool changes.

Preventing Thermal Damage

- Material Integrity: Different materials have specific temperature thresholds beyond which their integrity may be compromised. Cooling prevents the spindle and the workpiece from reaching excessive temperatures, preserving the structural and mechanical properties of the materials being machined.

- Reducing Thermal Stress: Rapid heating and cooling cycles, as experienced during machining, can induce thermal stress in the spindle and surrounding components. Cooling helps mitigate these stresses, preventing distortion, warping, or cracking of critical parts.

- Preventing Overheating: Continuous high-speed machining generates substantial heat. Without effective cooling, the spindle could overheat, leading to thermal degradation of lubricants, deterioration of bearings, and other mechanical failures.

Optimizing Machining Speeds

- Consistent Performance: Cooling allows for the maintenance of consistent spindle speeds. Fluctuations in temperature can lead to variations in the viscosity of lubricants and affect the overall efficiency of the spindle, potentially compromising machining speeds and performance.

- Increased Productivity: By maintaining optimal temperatures, cooling contributes to increased productivity by allowing for higher cutting speeds and feeds without compromising tool life.

Minimizing Noise and Vibration

- Noise Reduction: Effective cooling can contribute to reducing noise generated during machining operations, especially in the case of water-cooled spindles, which tend to be quieter compared to air-cooled counterparts.

- Vibration Control: Temperature-induced variations in spindle dimensions can contribute to unwanted vibrations. Cooling helps control thermal expansion, minimizing the risk of vibrations that can affect machining precision.

Cooling in spindle operation is not merely a comfort measure but a fundamental aspect that directly impacts the efficiency, precision, and longevity of machining processes. It enables CNC machines to operate at their full potential, ensuring consistent performance and the production of high-quality machined components.

Understanding Water Cooling Spindle

Water cooling spindles operate by circulating coolant, usually water or a water-based solution, through a closed-loop system within the spindle. This coolant absorbs heat generated during the machining process and carries it away, maintaining a consistent temperature around the spindle. Understanding the composition, advantages, and precautions of water-cooled spindles will provide a reference for selecting the appropriate type of spindle for CNC machines.

Components of a Water Cooling Spindle

- Spindle Motor: The core of the water-cooling spindle, converts electrical power into mechanical motion, driving the rotation of the spindle.

- Water Pump: Responsible for circulating coolant (usually water or a water-based solution) through the closed-loop system. The pump ensures a consistent flow to carry away heat.

- Radiator/Heat Exchanger: Facilitates heat exchange between the circulating coolant and the surrounding air. This component helps in dissipating heat absorbed by the coolant.

- Tubes and Fittings: Connect the various components, forming a closed-loop system. The tubes carry the coolant to and from the spindle, facilitating the heat exchange process.

- Coolant Reservoir: Holds the coolant when it is not actively circulating through the system. This reservoir ensures a continuous supply of coolant for effective heat dissipation.

Operation Mechanism of Water Cooling Spindle

- Heat Absorption: During CNC machining, the cutting tool generates heat due to friction and material removal. The water-cooling spindle absorbs this heat.

- Circulation: The water pump circulates the heated coolant away from the spindle to the radiator/heat exchanger.

- Heat Exchange: The radiator facilitates the exchange of heat between the coolant and the surrounding air. This process cools the coolant, preparing it for recirculation.

- Coolant Return: Cooled coolant is then pumped back into the spindle, completing the closed-loop cycle.

Advantages of Water Cooling Spindle

- Efficient Temperature Control: Water has a high heat capacity, allowing it to absorb and carry away more heat than air. This results in more efficient temperature control, preventing overheating of the spindle. Suitable for prolonged machining sessions and heavy-duty applications where heat generation is significant.

- Consistent Performance: The ability to maintain a stable operating temperature contributes to consistent spindle performance, minimizing thermal expansion and contraction that could affect machining precision.

- Suitable for Heavy-Duty Applications: Water cooling is particularly effective for heavy-duty machining tasks that generate substantial heat. It ensures the spindle remains within the optimal temperature range.

- Reduced Noise: Water cooling systems are often quieter compared to air cooling counterparts, contributing to a quieter working environment.

- Longevity: The efficient cooling provided by water cooling can contribute to the longevity of the spindle and other machine components.

Disadvantages of Water Cooling Spindle

- Complexity: Water cooling systems are more complex than air cooling systems due to the additional components. Regular maintenance is therefore required to prevent problems such as blockages or leaks.

- Initial Cost: Water cooling spindles typically have a higher upfront cost compared to air cooling spindles. This includes the cost of the pump, radiator, and associated components.

- Space Requirements: The additional components of a water cooling system may require more space in the CNC router

Understanding Air Cooling Spindle

Unlike water cooling spindles, which use a closed-loop water circulation system, air cooling spindles rely on fans to dissipate heat and maintain optimal operating temperatures. While they may not offer the same level of heat dissipation as water cooling spindles, they provide simplicity and cost-effectiveness for certain machining requirements. In this part, we introduce to you the composition, advantages and disadvantages, and operating mechanism of the air-cooled spindle.

Components of an Air Cooling Spindle

- Spindle Motor: The core component that converts electrical power into mechanical motion, driving the rotation of the spindle.

- Cooling Fan(s): One or more fans are used to create airflow around the spindle. This airflow is instrumental in dissipating heat generated during machining.

- Heat Sink: Enhances heat dissipation by providing additional surface area for the air to cool. The heat sink absorbs and disperses heat from the spindle.

- Enclosure: Contains the components and directs the airflow over the spindle. The enclosure is designed to optimize the cooling process.

Operation Mechanism of Air Cooling Spindle

- Heat Dissipation: During CNC machining, the cutting tool generates heat due to friction and material removal. The air-cooling spindle relies on fans to dissipate this heat.

- Airflow: The cooling fan(s) create airflow around the spindle. This airflow helps in carrying away the heat generated during machining.

- Heat Exchange: The heat sink enhances the heat exchange process by providing additional surface area for heat dissipation. It absorbs heat from the spindle and allows the surrounding air to cool it.

- Continuous Operation: The continuous operation of the cooling fan(s) ensures that the spindle remains within the optimal temperature range during the machining process.

Advantages of Air Cooling Spindle

- Simplicity: Air cooling spindles are simpler in design compared to water cooling spindles. They have fewer components, making them easier to install and maintain.

- Cost-Effectiveness: Air cooling spindles are often more cost-effective upfront due to their simpler design and fewer components. This can be advantageous for those with budget constraints.

- Portability: Air cooling spindles are generally more compact and lightweight, making them suitable for applications where machine portability is a key consideration.

Disadvantages of Air Cooling Spindle

- Temperature Control: Air cooling may struggle to maintain consistent temperatures in demanding or prolonged machining tasks. The efficiency of heat dissipation is generally lower compared to water cooling.

- Heat Dissipation: While effective for many applications, air cooling may not be as efficient as water cooling, especially in heavy-duty tasks where substantial heat is generated.

- Noise: Air cooling systems may produce more noise compared to water cooling systems. Noise levels can be a consideration in environments where a quieter operation is desired.

Performance Comparison

Water cooling spindles and air cooling spindles have different performance due to different working principles and designs. Here we compare their three main properties to provide you with a reference for choosing the right spindle type.

Heat Dissipation Efficiency

- Air Cooling Spindle: The design is simpler, allowing for uncomplicated heat dissipation. Air-cooled spindles can dissipate heat relatively quickly due to the direct exposure of the spindle to ambient air. However, because air has a lower heat capacity than water, limiting the overall capacity of the system to dissipate heat efficiently. In heavy-duty machining tasks with prolonged operations, air-cooled spindles may struggle to dissipate heat effectively, leading to potential thermal issues.

- Water Cooling Spindle: Water has a higher heat capacity than air, allowing for more efficient absorption and dissipation of heat, leading to more consistent and controlled temperatures during machining. The high efficiency of heat dissipation makes water-cooled spindles ideal for heavy-duty machining tasks with prolonged cutting times.

Temperature adjustment

- Water Cooling Spindle: Provides more precise temperature control and stability. Temperature adjustment in water cooling spindles is typically achieved by controlling the flow rate and temperature of the circulating water. This can be managed using a dedicated cooling system with a thermostat or other temperature control devices.

- Air Cooling Spindle: This relies on ambient air for cooling, and as a result, its temperature control may be less precise compared to water cooling spindles. The temperature can be influenced by external factors, such as the surrounding environment and air circulation. Adjusting the temperature in air cooling spindles is often less direct. Some systems may include features like fan speed control to influence the cooling effect, but they may not provide as fine-tuned control as water cooling systems.

Maintenance Precautions

- Water Cooling Spindle: Periodic inspections of the water circulation system are necessary to ensure there are no leaks, and the system is functioning properly. The quality of the water used in the cooling system should be monitored to prevent issues like mineral buildup or corrosion. Some systems may require the use of distilled water or water with added coolants. If the system includes a thermostat for temperature control, it should be calibrated periodically to ensure accurate temperature regulation.

- Air Cooling Spindle: Regularly check fan functionality, cleanliness, and potential obstructions to ensure that the fan can be used for proper cooling. To maintain optimal cooling efficiency, the heat sink needs to be regularly cleaned of dust and debris that blocks airflow. Air cooling spindles often have bearings that require periodic lubrication. Checking and maintaining proper lubrication are essential for extending bearing life. If the system includes temperature sensors, periodic calibration may be necessary to ensure accurate temperature monitoring.

How to choose spindle cooling type?

Choosing the appropriate spindle cooling type—whether water cooling or air cooling—requires careful consideration of various factors to ensure optimal performance in CNC machining applications. Here are key factors to consider when selecting a spindle cooling type.

- Application Requirements: Consider the nature of your machining tasks. Water-cooled spindles are often preferred for heavy-duty applications with extended machining times, while air-cooled spindles may be suitable for lighter tasks with shorter operating periods.

- Precision and Stability: Tight Tolerances: If your application demands high precision and tight tolerances, a water-cooled spindle might be more suitable due to its better temperature control and stability.

- Heat Dissipation Needs: Assess the heat dissipation requirements of your machining tasks. Water-cooled spindles are generally more efficient at dissipating heat, making them suitable for continuous and high-speed operations.

- Operating Environment: Consider the ambient temperature and the presence of dust in your machining environment. Air-cooled spindles are simpler and maybe more robust in environments with high temperatures or significant dust.

- Initial Cost and Budget: Evaluate your budget constraints. Air-cooled spindles are often more cost-effective upfront due to their simpler design, while water-cooled spindles may have higher initial costs associated with the cooling system.

- Maintenance Considerations: Assess the level of maintenance you are willing to undertake. Air-cooled spindles are generally simpler to maintain, while water-cooled spindles may require more attention to the cooling system components.

- Noise Levels: Consider the noise levels associated with each cooling type. Water-cooled spindles tend to be quieter due to the closed-loop water circulation, whereas air-cooled spindles may produce more noise.

- Space Constraints: Evaluate the available space in your CNC router Water-cooled systems might require more space for the cooling infrastructure, including pumps and hoses, while air-cooled spindles are more compact.

Summarize

The choice between water cooling and air cooling spindles depends on various factors, including the nature of machining tasks, precision requirements, budget considerations, and available space. Water cooling offers superior heat dissipation and temperature control, making it ideal for high-precision and intensive machining. On the other hand, air cooling provides a simpler, cost-effective solution suitable for general machining purposes. Ultimately, the decision should align with the specific needs and constraints of the CNC machining setup. By carefully considering the advantages and disadvantages outlined in this article, CNC machinists can make an informed decision that aligns with their machining needs, ensuring optimal performance and longevity of their equipment.

AccTek CNC equips the CNC router machine purchased by the user with the correct type of spindle according to the user’s different application scenarios. The optional range of water-cooled spindle power is 1.5KW-7.5KW, and the optional range of air-cooled spindle power is 1.5KW-12KW. If you are not sure which spindle type or power level is more suitable for your machine, contact us and AccTek’s professional sales team will provide you with more help.

Want To get a good machine?

Click the button, our CNC Experts will contact you and send you a solution.