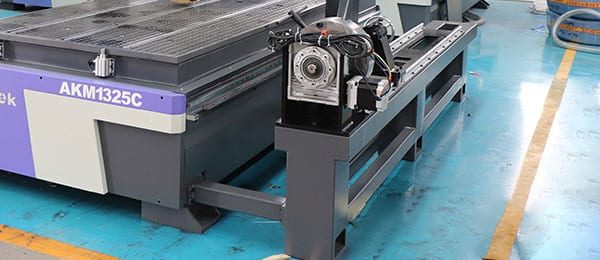

Economic 1325 Rotary Axis CNC Router for Cylindrical Workpiece

The AKM1325-R CNC router is a reliable, high-performance machine designed for precise engraving and cutting. Perfect for woodworking, plasticworking, and other precision applications.

4 reviews for AKM1325-R CNC Router

George –

AccTek CNC has made my first processing venture a success, and I owe it all to their invaluable support. Without them, I wouldn’t have achieved this milestone. Thank you very much for your expertise and assistance.

Francis –

As a seasoned professional in the furniture industry, AccTek CNC has revolutionized my production of wooden doors. Highly recommended by a friend, the wood CNC router has significantly increased processing efficiency, saving both manpower and time. Grateful for this game-changer in the furniture business.

Edith –

Purchased a CNC router in 2019 after a successful test by my colleague David at the AccTek factory. The machine’s quality and service have consistently proven exceptional. Grateful for a wise investment that continues to deliver excellence.

Sabrina –

AccTek CNC’s professionalism shines through its patient and thorough explanations. Grateful to the staff for guiding me through the intricacies of my CNC router purchase. Their dedication to customer understanding is commendable, making the entire experience worthwhile. Highly recommend their expertise and support.