Economical ATC CNC Router For Customizable Size

The AKM-C1 CNC router combines precision and efficiency for woodworking and engraving, offering advanced features, durable construction, and a user-friendly design for versatile applications.

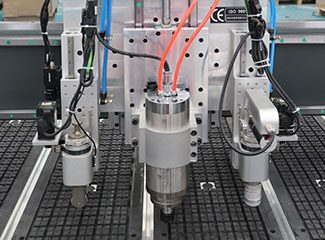

The rotating axis adds enhanced flexibility to the CNC router, allowing for 4-axis machining. It enables the processing of cylindrical and complex shapes, making it ideal for applications like engraving on round surfaces and creating 3D contours.

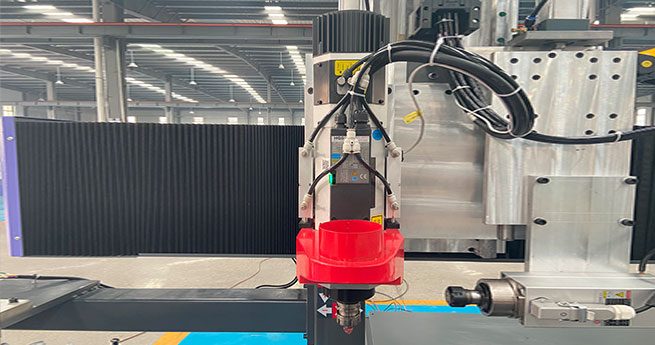

The 360° rotating cutting saw offers versatile cutting capabilities by allowing full rotational movement. This optional configuration enables precise angle cuts and seamless processing of various materials, making it ideal for complex shapes and detailed, multi-dimensional designs.

The drilling unit enhances the CNC router’s capabilities by enabling precise drilling operations. This optional feature allows for multiple hole sizes and depths, making it ideal for applications in woodworking, and customized part production.

The oscillation knife head for cutting soft and flexible materials such as foam, rubber, and textiles. Its oscillating blade provides smooth, precise cuts, perfect for detailed and intricate shapes in various industries.

The plasma cutting head enables high-precision cutting of metals such as steel, aluminum, and brass. It delivers clean, fast cuts with minimal heat distortion, making it ideal for heavy-duty industrial applications.

The auto-loading & unloading device is an optional feature that automates material handling, improving efficiency and reducing labor costs. It seamlessly loads and unloads workpieces, ensuring continuous, high-speed operation for large-scale production runs.

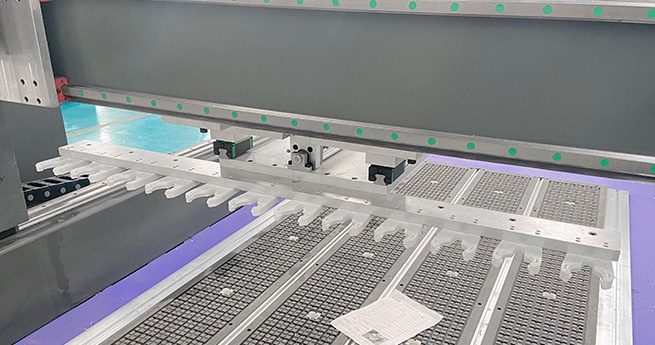

The sunken worktable is designed to accommodate taller workpieces and offers increased flexibility for integrating rotary axes, expanding your machining capabilities. Its recessed design provides a stable foundation for your workpiece, ensuring enhanced precision and stability during operations.

The desktop worktable offers unparalleled flexibility, making it ideal for a wide variety of CNC projects. Positioned at an accessible height, it allows for easy loading and unloading of materials. Whether you're tackling intricate details or larger projects, this design ensures optimal adaptability and efficiency for all your machining tasks.

| Model | AKM1325C1 | AKM1530C1 | AKM2030C1 | AKM2040C1 |

| X, Y, Z Working Area | 1300x2500x250mm | 1500x3000x250mm | 2000x3000x250mm | 2000x4000x250mm |

| Worktable Size | 2150x3420mm | 2350x3920mm | 2850x3920mm | 2850x4920mm |

| X, Y, Z Traveling Positioning Accuracy | 0.01/300mm | |||

| X, Y, Z Repositioning Accuracy | 0.03mm/300mm | |||

| Worktable Type | T-slot and Vacuum Worktable | |||

| Frame | Heavy Steel Tube Structure | |||

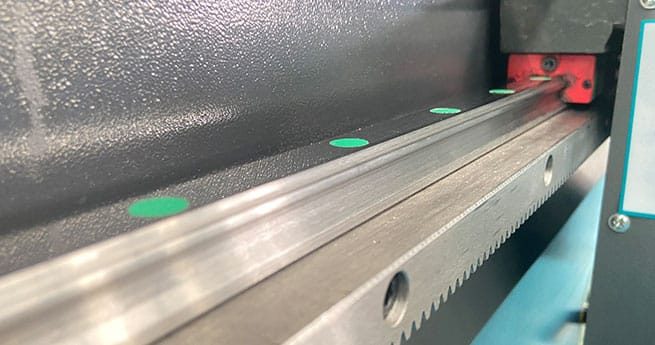

| X, Y Structure | Rack, and Pinion Drive, Hiwin Rail Linear Bearings | |||

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw | |||

| Spindle Power | 9.0KW HQD Air Cooling ATC Spindle | |||

| Drive Motors | Easy Servo Motor | |||

| Operation System | Mach3 Control System | |||

| Working Voltage | AC380V/50/60HZ, 3PH (Option: 220V) | |||

| X, Y Resolution | <0.03mm | |||

| Running Environment Temperature | 0-45℃ | |||

| Relative Humidity | 30%-75% | |||

We offer free lifetime maintenance to ensure your machine remains running at its best for years to come.

4 reviews for AKM-C1 CNC Router

Mercedes –

AccTek CNC exhibited the utmost professionalism during my CNC router selection process. Grateful for their assistance in choosing the best processing machine for my needs. Now, with the received machine, I look forward to enjoying its capabilities. Highly recommend their expertise and service.

Virginia –

AccTek CNC router delivers on its promise. The first job of creating kitchen facades was executed swiftly and efficiently. The machine’s performance exceeded expectations. AccTek CNC proves to be an invaluable asset for precision work in my business. Highly recommended for quality results.

Patrick –

AccTek CNC router exceeded expectations. The machine, received yesterday, was exceptionally well-packaged. Its impressive accuracy makes it a valuable tool for my projects. Highly recommend it for precision and reliable performance.

Caspar –

Impressed with my AccTek CNC router, which arrived in mint condition, and well-packaged. The machine works beautifully, and I appreciate the attention to detail. AccTek CNC’s commitment to quality is evident. Highly recommended for reliable and efficient performance.