Semi-Enclosed 4040 Metal ATC CNC Router

The AK4040C CNC router is an advanced ATC CNC router designed for metal engraving. It offers high precision, automated tool changes, and efficient performance for intricate metalworking tasks.

| Model | AK4040C | AK6060C |

| X, Y, Z Working Area | 400x400x200mm | 600x600x200mm |

| Worktable Size | 400x400mm | 600x600mm |

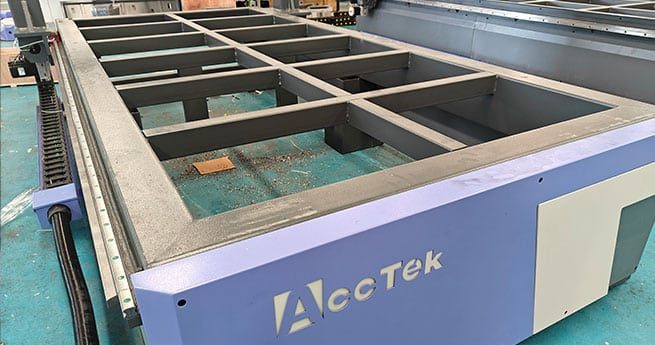

| Worktable Surface | T-Slot Extrusions | |

| Worktable Frame | Whole Cast Steel | |

| Drive Motors | Hybrid Servo Motors | |

| Traveling Positioning Accuracy | ±0.005mm | |

| Repositioning Accuracy | ±0.003mm | |

| Transmission | TBI Ball Screw from Taiwan | |

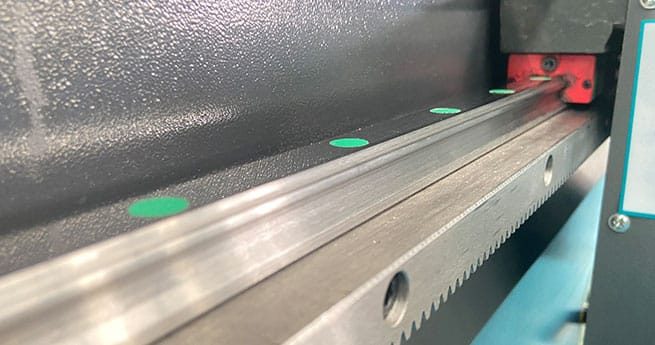

| Guide Rails | Hiwin Linear Guide Rails | |

| Max Power Consumption (Without Spindle) | 0.8KW | |

| Max Rapid Travel Rate | Max Rapid Travel Rate | |

| Max Working Speed | 8000mm/min | |

| Spindle Power Motor | Spindle Power Motor | |

| Spindle Speed | 0-18000 RPM | |

| Operating System | Weihong NK280B Controller | |

| Inverter | Delta Inverter | |

| Running Environment | Temperature: 0℃~45℃; Relative Humidity: 30%~75% | |

We offer free lifetime maintenance to ensure your machine remains running at its best for years to come.

4 reviews for AK4040C CNC Router

Todd –

Heartfelt thanks to AccTek CNC! My CNC router has exceeded expectations, and I am thoroughly satisfied. AccTek’s commitment to quality and excellent service makes it a standout choice. Highly recommend to anyone seeking top-notch CNC solutions.

Brandon –

Enamored with my AccTek CNC router, it works exceptionally well. Almost fell in love with it! Planning to work with AccTek CNC again as I upgrade my business. Thank you for your exceptional product and service.

Emily –

Exceptionally satisfied with my AccTek CNC router. The machine performed flawlessly upon powering up, enabling me to initiate tests and foster business growth. AccTek CNC’s commitment to quality makes it my go-to choice for robust CNC solutions.

John –

After 2 weeks of using my AccTek CNC router, I’m thoroughly impressed. The precision, robust welding, and professional training have elevated my projects, cabinets, tables, nightstands, and more. For anyone considering a CNC router, I highly recommend AccTek CNC for their top-notch quality and service.