Table of Contents

CNC Router Safety Operation Guide

- 5-8 Min Read

CNC (Computer Numerical Control) routers are powerful tools used in various industries for cutting, carving, and shaping materials with precision. Operating a CNC router is a precision task that requires a thorough understanding of both the machine’s capabilities and the critical safety protocols associated with its operation. This CNC Router Safety Operation Guide is designed to provide comprehensive guidelines to ensure a secure working environment and promote responsible machine use. Whether you are a seasoned CNC operator or someone new to these machines, understanding and implementing safety measures can help prevent accidents, maintain equipment integrity, and optimize the overall efficiency of the machining process. By following these guidelines, operators can contribute to a culture of safety, fostering an environment where CNC routers can be utilized to their full potential with confidence and reliability.

The importance of CNC router safety operation

Operating a CNC router involves a symphony of movements and processes orchestrated by sophisticated programming. While these machines boast remarkable accuracy and speed, the convergence of human interaction and technological prowess necessitates a meticulous focus on safety protocols. Here, we learn about the layers of significance attached to the safe operation of CNC routers and the benefits of implementing safety guidelines for production.

- Operator Safety: The primary concern in any manufacturing environment is the safety of the operators. CNC routers involve moving parts, sharp tools, and various potential hazards. A secure operation ensures that operators are protected from accidents, reducing the risk of injuries.

- Equipment Protection: CNC routers are significant investments for businesses. Ensuring the security of these machines helps protect them from damage or misuse, extending their lifespan and optimizing their efficiency. Proper maintenance and adherence to safety protocols contribute to the longevity of the equipment.

- Prevention of Accidents: CNC routers involve high-speed movements, sharp cutting tools, and various mechanical components. Adhering to safety protocols and guidelines helps prevent accidents, reducing the likelihood of incidents such as tool collisions, material ejections, or unexpected machine movements.

- Quality Output: Security measures directly impact the quality of the machined output. A secure setup, including proper workpiece fixation and toolpath verification, helps prevent errors that could lead to defective products. Accurate and consistent operation leads to high-quality products and maintains the reputation of the manufacturing process.

- Data Protection: CNC routers are driven by computer programs that contain valuable design and manufacturing information. Safe operation, including secure data handling, protects intellectual property, trade secrets, and sensitive information from unauthorized access or manipulation.

- Compliance with Regulations: Many industries and regions have specific safety regulations and standards that businesses must adhere to. Safe operation ensures that businesses adhere to industry and regional safety guidelines, avoiding potential fines, legal issues, and negative reputational impacts.

- Reduced Downtime: Safe operation minimizes the occurrence of accidents and breakdowns. This, in turn, reduces unexpected downtime for repairs and maintenance, ensuring continuous production and meeting deadlines.

- Cost Savings: Implementing security measures, regular maintenance, and proper training contribute to cost savings in the long run. Preventing accidents and equipment damage reduces the need for costly repairs, downtime, and potential legal liabilities. Businesses can allocate resources more efficiently when they are not constantly addressing safety-related issues.

- Employee Confidence: A safe working environment fosters confidence among employees. When operators feel secure in their working conditions, they are more likely to be productive, engaged, and committed to maintaining safety standards. A secure work environment fosters a culture of responsibility and accountability among the workforce.

- Continuous Improvement: Regularly evaluating and enhancing CNC router security contributes to a culture of continuous improvement. This includes staying updated on safety protocols, incorporating new technologies, and learning from past incidents to refine safety procedures.

- Adherence to Best Practices: Following best practices in CNC router security ensures that the machine operates within its designed parameters. This includes proper tooling, work holding, and operational procedures. Adherence to best practices enhances efficiency and reduces the likelihood of errors.

- Legal and Ethical Responsibility: Businesses have a legal and ethical responsibility to provide a safe working environment for their employees. Safe operation of CNC routers aligns with these responsibilities, protecting both the workforce and the organization.

How to operate CNC router safely?

Operating a CNC router safely provides the basis for preventing accidents, protecting personnel, and ensuring the longevity of the machine. Here is a comprehensive safety operation guide for CNC routers. Here we will cover a range of safety considerations, from personal protective equipment (PPE) and machine inspection to emergency procedures and continuous learning. By following these safety guidelines, operators can contribute to a secure working environment, prevent accidents, and promote the efficient and responsible operation of CNC routers.

Personal Protective

- Mandate the use of appropriate PPE, including safety glasses, hearing protection, and closed-toe shoes.

- Depending on the materials being machined, additional PPE such as dust masks or gloves may be necessary.

- Secure loose clothing and hair. Tie back long hair and avoid wearing loose clothing or accessories that could get caught in the machine.

Machine Setup and Preparation

- Machine inspection. Inspect the CNC router before each use for signs of wear, damage, or loose components. If any issues are identified, do not operate the machine and contact service personnel for repair.

- Tool inspection. Inspect cutting tools for damage or wear before starting a job. Replace tools that are dull or damaged.

- Material compatibility. Verify that the chosen cutting tools and machining parameters are suitable for the specific material being processed. Follow manufacturer recommendations for cutting speeds, feeds, and tool selection.

- Material Fixation. Check materials for suitability and secure placement on the work table. Verify that the workpiece is securely fastened to prevent movement during machining.

- Workpiece size and clearance. Verify that the workpiece size is within the machine’s capacity. Ensure there is sufficient clearance for all tool movements.

- Check the weight capacity of the CNC router and ensure that the material being transported falls within the specified limits. If the material is heavy or bulky, use suitable lifting equipment.

- Keep the workspace clean, organized, and free from clutter. Clear the workspace of unnecessary tools, materials, or obstacles to prevent interference with the machine’s movements. Ensure adequate lighting for clear visibility.

Safe Operating Procedures

- Homing and Zeroing: Always home and zero the machine before starting a new job. Confirm the correct work offsets and tool lengths.

- Spindle Speed and Feed Rates: Set appropriate spindle speeds and feed rates according to material and tool specifications.

- Programming and Simulation: Double-check CNC programs for errors before initiating a job. Use simulation features to preview toolpaths and identify any potential collisions or issues.

- Supervision: Assign a responsible and trained operator to oversee the CNC router during operation. Avoid leaving the machine unattended, especially during critical phases of the machining process.

- No Unauthorized Access: Restrict access to the CNC router to trained and authorized personnel only. Keep bystanders at a safe distance.

- Dust Extraction and Ventilation: Implement an effective dust extraction system to minimize airborne particles. Ensure proper ventilation in the workspace to mitigate the risk of inhaling harmful fumes or dust.

Machine Inspection and Maintenance

- Keep the machine clean from debris, dust, and excess material to prevent interference with moving parts.

- Schedule routine maintenance, including lubrication and calibration, as recommended by the manufacturer to ensure optimal performance.

- Conduct regular inspections of the CNC router for any signs of wear, damage, or malfunction. Promptly address any issues or abnormalities.

- Implement lockout/tagout procedures during maintenance to prevent accidental startup. Ensure energy sources are properly isolated.

Safety Training and Communication

- Read and understand the manual. Familiarize yourself with the CNC router’s user manual, including safety guidelines and operational instructions.

- Ensure that operators receive proper training on CNC router operation. Familiarize operators with the machine’s control panel, emergency stop procedures, and the specific software used for programming.

- Stay informed about updates, new features, and safety improvements related to the CNC router. Encourage a culture of continuous improvement and learning within the workplace.

- Encourage operators to report any concerns or malfunctions promptly. Foster open communication regarding safety within the workplace.

Emergency Response

- Know the location of the emergency stop button and how to use it in case of an emergency.

- Establish clear emergency procedures and evacuation routes. Ensure all personnel is aware of these procedures.

- Display emergency contact information and procedures in a visible and accessible location.

- Fire safety. Have a fire extinguisher nearby and ensure personnel know how to use it. Keep flammable materials away from the CNC router.

Summarize

The comprehensive safety operation guide for CNC routers serves as an indispensable compass, guiding operators and stakeholders through the intricate landscape of precision manufacturing. Through the exploration of key facets such as training, personal protective equipment, machine maintenance, and emergency procedures, we have unraveled the intricate web of considerations that constitute safe CNC router operation. As industries continue to harness the transformative capabilities of CNC routers, it becomes incumbent upon us to prioritize safety not merely as a regulatory obligation but as an ethical responsibility.

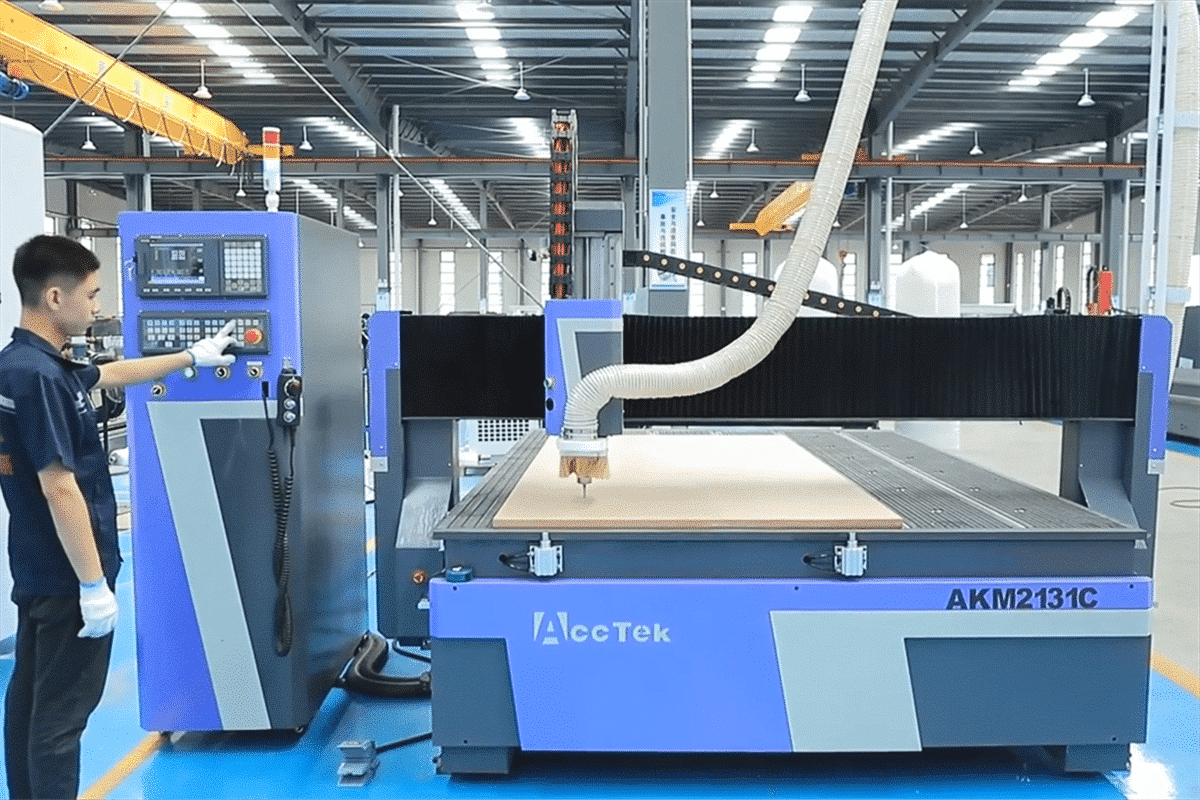

As a manufacturer and supplier of CNC routers, AccTek CNC has emerged as a trusted name known for its commitment to innovation and reliability. We are committed to providing various types of CNC routers to meet the unique needs of different industries. Whether one seeks intricate detailing in woodworking, the robustness required for heavy-duty tasks, or the precision demanded by delicate materials, AccTek CNC has curated a diverse selection that aligns with the multifaceted needs of today’s industries. Contact us to get your exclusive CNC router customization solution.

Want To get a good machine?

Click the button, our CNC Experts will contact you and send you a solution.