Woodworking Industry

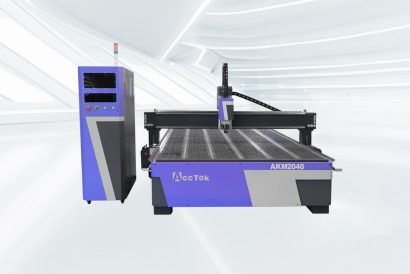

Application of CNC Router in The Woodworking Industry

CNC Router Improves Production Technology in The Woodworking Industry

Joinery

CNC routers can assist in creating precise and intricate joinery, such as dovetails, mortise and tenon joints, and finger joints. The machine ensures a snug fit and precise alignment, contributing to the overall strength and quality of the joint.

Inlays And Marquetry

Inlays and marquetry involve embedding different wood pieces to create decorative patterns. CNC routers can cut precise pockets and shapes for inlays, facilitating intricate designs and minimizing gaps between pieces.

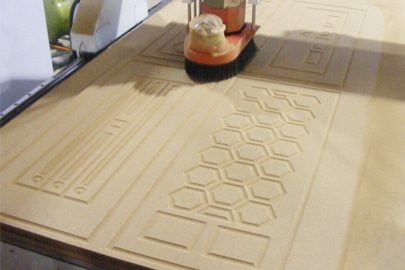

Precision Cutting

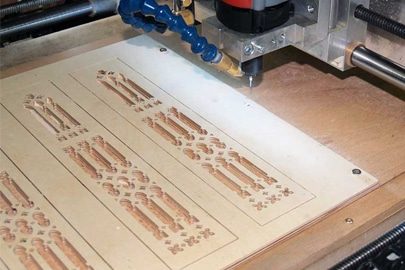

CNC routers excel at precision cutting, allowing for intricate and detailed designs that may be challenging or impossible to achieve manually. This is especially useful for creating complex joinery, inlays, and detailed patterns.

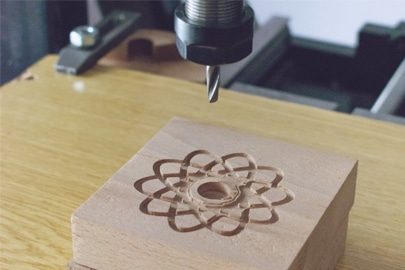

Carving And Engraving

CNC routers are highly effective at carving and engraving tasks. They can produce intricate designs, text, and decorative elements with consistent depth and accuracy.

Repetitive Tasks

CNC routers are excellent for repetitive tasks such as cutting multiple identical pieces or creating a series of similar carvings. The machine can replicate designs with high accuracy, ensuring consistency across a batch of workpieces.

Complex 3D Shapes

Creating complex 3D shapes manually can be time-consuming and challenging. CNC routers can efficiently carve intricate 3D designs with precision, allowing woodworkers to explore more elaborate and artistic projects.

V-Carving And Texturing

CNC routers equipped with V-carving bits can create textured surfaces and carve detailed text with precision. This is useful for adding decorative elements, signage, or personalized details to woodworking projects.

Prototyping

CNC routers are valuable for prototyping new designs quickly. Woodworkers can experiment with different shapes and forms without the time-consuming process of manual construction, allowing for rapid iteration and refinement.