Musical Instrument Industry

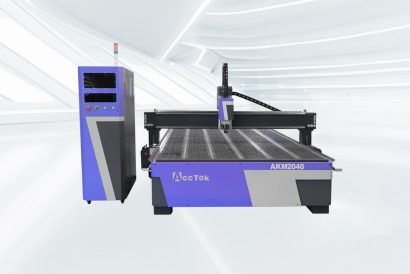

Application of CNC router in the musical instrument industry

Musical Instrument Production Technology That CNC Router Can Improve

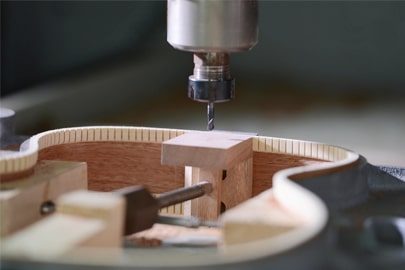

Mold And Template Creation

A CNC router can simplify the creation of molds and templates for musical instrument parts. Whether shaping the body of a guitar or the template for a complex inlay job, CNC technology can produce these important tools with precision and efficiency.

Custom Engraving Available

Instruments with customized body shapes can be efficiently produced using a CNC router. CNC router enables customizable wood carving, allowing manufacturers to experiment with unique designs, textures, and patterns on instrument bodies, necks, and other components.

Headstock Molding And Engraving

CNC routers specialize in shaping and carving the headstocks of guitars and other stringed instruments. Whether carving unique shapes or adding decorative elements, CNC technology allows for consistent and precise execution.

Neck Sculpting And Shaping

The CNC router plays a vital role in carving and shaping the neck of the instrument. It creates consistent contours, fretboard detail, and ergonomic contours that help improve the playability and comfort of the instrument.

Mosaic Design And Execution

Using a CNC router can greatly improve the artistry of musical instrument inlay work. It enables precise cutting and shaping of decorative elements, allowing complex designs that would be difficult to achieve manually.

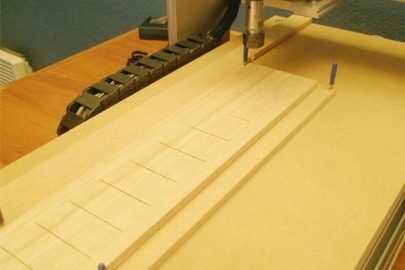

Efficient Mass Production

For mass production of musical instruments, CNC routers increase efficiency by automating repetitive tasks. This includes high-precision cutting, forming, and engraving parts, resulting in consistent quality from batch to batch.

Complex Joinery

CNC routers excel at performing complex joinery tasks in musical instrument manufacturing. This includes precision sculpting of the neck-body joint to ensure a snug fit and optimal vibration transfer, resulting in enhanced instrument performance.

Optimize Material Usage

CNC router contributes to the sustainability of musical instrument production by optimizing material use. These machines can be programmed to cut parts, minimizing waste and the environmental impact of the manufacturing process.