- 13-18 Min Read

As CNC routers become increasingly essential in woodworking, metalworking, signage, and other precision-based industries, more businesses are turning to overseas suppliers for cost-effective, feature-rich machines. Buying from international manufacturers can offer significant advantages, including competitive pricing, a wider selection, and advanced technology options. However, purchasing equipment from abroad also comes with added complexities and risks.

From verifying technical specifications to ensuring after-sales support, there are many factors to weigh before finalizing your order. In this guide, we’ll walk you through the key considerations to help you make a confident and informed decision when buying a CNC router from an overseas supplier.

Define Your Requirements Clearly

Before reaching out to any overseas supplier, it’s essential to have a clear understanding of your specific needs. This will not only help you choose the right machine but also ensure the supplier can deliver a solution that meets your expectations.

Intended Use

The first step in defining your requirements is to determine what you’ll be using the CNC router for. CNC routers are versatile, but machines designed for specific industries often have optimized configurations.

- Woodworking: Ideal for cabinetry, furniture making, or sign carving. You may need features like vacuum tables and dust collection.

- Metalworking: Requires a stronger frame, higher spindle power, and possibly cooling systems for cutting aluminum or soft metals.

- Plastics and Composites: May need specialized tooling and dust management.

- Signage: Often benefits from a large bed size and compatibility with a range of materials like acrylic, PVC, aluminum, and foam boards.

Clearly stating your intended application helps suppliers recommend the most suitable machine specifications.

Material Compatibility

Not all CNC routers are designed to handle every type of material. The machine’s rigidity, spindle type, cutting speed, and tooling must align with the materials you intend to work with.

- Soft Materials: MDF, plywood, foam, and acrylic are commonly handled by standard CNC routers.

- Hardwoods and Dense Plastics: Require a robust spindle and stable machine body to prevent vibration and ensure clean cuts.

- Non-ferrous Metals (e.g., Aluminum): Call for a higher spindle speed, stronger build, and often cooling or lubrication features.

- Composites and Laminates: May generate dust or require specialized bits to avoid delamination or tool wear.

Always confirm that the machine can cut your primary materials efficiently and safely.

Size and Capacity Needs

The size of your typical workpieces will influence the machine’s required bed size and axis travel. Oversizing can lead to wasted floor space and cost, and undersizing can limit your production capabilities.

- Table Size (X and Y Axis): Choose a worktable size that accommodates your largest material dimensions with extra margin for clamps and fixtures.

- Z-Axis Travel (Height Capacity): Ensure the Z-axis can move high enough to work with your thickest materials or parts with fixtures.

- Production Volume: If you have high production needs, you may also want dual spindles, tool changers, or automatic loading systems to increase throughput.

Required Accuracy and Functionality

Precision matters, especially if your work involves detailed designs, small components, or tight-fitting assemblies.

- Tolerance Levels: Know the level of dimensional accuracy you need (e.g., ±05mm). This affects the choice of linear guides, drive systems (ball screw vs. rack and pinion), and machine structure.

- Spindle Power and Speed: Affects how quickly and cleanly the machine can cut various materials. Higher wattage spindles are better for tough jobs but are more expensive.

- Features and Automation: Think about what features are important to your workflow, automatic tool changers (ATC), vacuum tables, rotary attachments, dust collection systems, or camera positioning systems.

All these features contribute to the machine’s productivity, flexibility, and ease of use.

Budget Range

Clearly establishing your budget helps you narrow down your options and make trade-offs between cost and features.

- Entry-Level Budget(under $4,000): Typically smaller desktop CNC routers with limited power, suited for hobby use or light prototyping.

- Mid-Range Budget($4,000–$10,000): Machines with decent size, spindle strength, and some automation. Suitable for small to mid-scale production.

- Industrial Budget($10,000 and up): Includes high-end machines with large work areas, robust frames, high-speed spindles, and automation. Suitable for heavy-duty, high-volume production.

Balancing your budget with long-term performance and reliability is key to making a wise investment.

By outlining your requirements in advance, you’ll be better prepared to communicate with suppliers, compare offers effectively, and avoid costly mismatches.

Comprehensive evaluation of CNC router suppliers

Choosing the right CNC router supplier is just as important as selecting the machine itself. With many options available worldwide, especially from overseas markets, it’s essential to evaluate each supplier thoroughly to ensure reliability, quality, and long-term support. This section provides a comprehensive review of key aspects to look for in a supplier so you can make an informed purchasing decision with confidence.

Evaluate the Supplier's Reputation and Reliability

When buying a CNC router from an overseas supplier, one of the most important steps is verifying that the company is trustworthy, experienced, and capable of delivering high-quality products and reliable service.

- Company History and Industry Experience: Start by researching how long the supplier has been in business and their track record in manufacturing CNC routers. A company with several years of experience is more likely to have refined its production processes, addressed quality issues, and built stable customer relationships.

- Online Reviews and Client Testimonials: Customer feedback on third-party platforms like Alibaba, Made-in-China, or Trustpilot offers valuable insights into product quality and service reliability. Client testimonials on the supplier’s website can also help, but always try to verify them independently.

- Case Studies or Client References: Many reputable suppliers share case studies that showcase how their machines are used in real-world applications. These often include photos, usage details, and outcomes from actual clients. You can also request direct references or speak to past customers to verify the supplier’s claims.

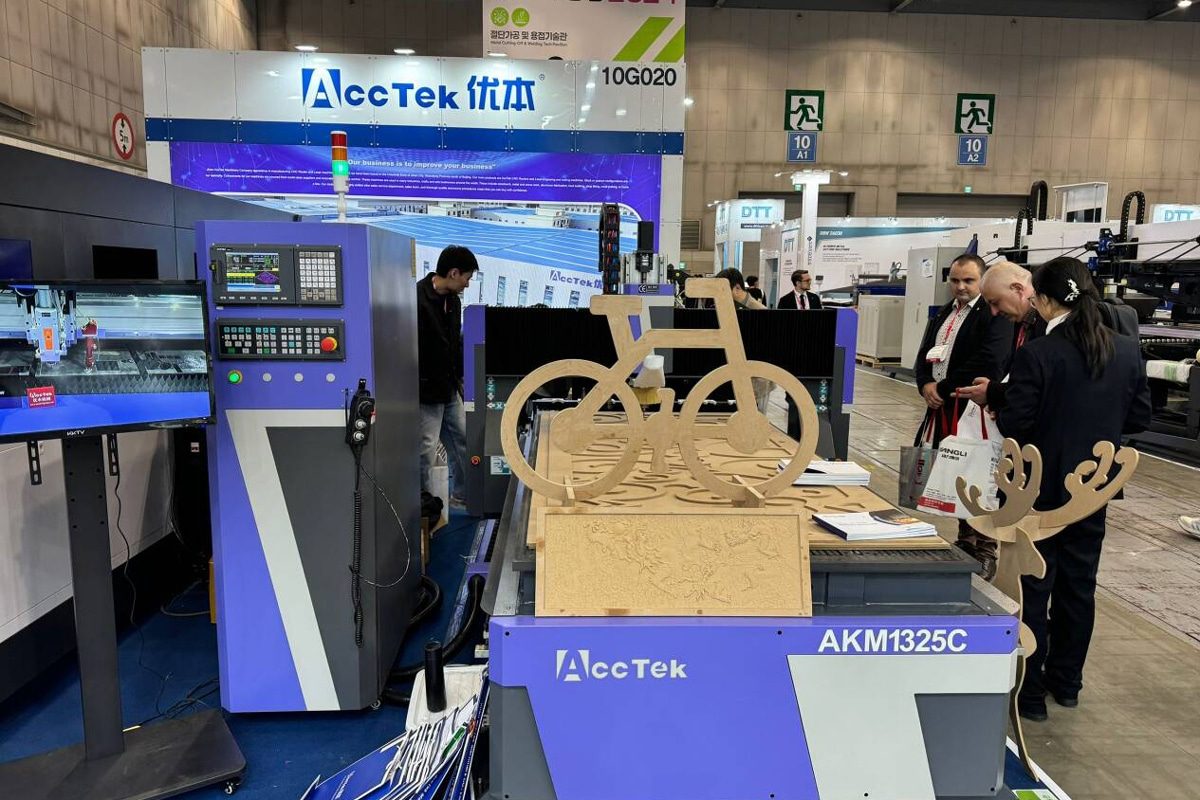

- Participation in Trade Shows: Suppliers that actively participate in international trade fairs are usually more credible. Trade show confidence in product quality and a commitment to global market standards. It also shows the supplier is actively engaged in industry developments and is serious about building long-term business partnerships.

Evaluate After-Sales Support and Training

After-sales service is a critical but often overlooked factor when buying a CNC router from an overseas supplier. Assessing the supplier’s after-sales support system helps ensure smooth installation, minimal downtime, and long-term productivity.

- Installation Assistance: Make sure the supplier outlines exactly what kind of support they provide during the setup process. Many overseas suppliers offer remote installation guidance through video calls, manuals, and tutorial videos. Some also provide virtual commissioning or support through platforms like WhatsApp or WeChat. While onsite installation is less common for international buyers, it may be available through local partners at an extra cost.

- Spare Parts Availability: Ensure that replacement parts are readily available and reasonably priced. Ask if spare parts can be shipped quickly to your country and whether the supplier offers a parts catalog with pricing. Ideally, they should provide guidance for replacing parts and ensure compatibility with your machine’s configuration.

- Online or In-Person Training Options: Some suppliers provide pre-recorded videos, user manuals, or live virtual sessions. Others offer in-person training if you visit their factory. Make sure the training covers not just machine operation, but also maintenance practices, safety protocols, and software usage.

- Technical Support Response Time: Fast and reliable technical support is a must when issues arise. Clarify how quickly the supplier typically responds to support requests, many aim to reply within 24 to 48 hours. Also, check what support channels are available, such as email, live chat, or direct messaging apps.

Consider Warranty Terms

A clear and comprehensive warranty is your safety net when buying a CNC router from an overseas supplier. It reflects the manufacturer’s confidence in their product and protects you from unexpected costs due to defects or component failures.

- Warranty Coverage Scope: Warranty coverage varies by supplier, so it’s important to clarify exactly what components are protected. A comprehensive warranty typically covers the machine frame, motors, drives, spindle, control system, and electrical components. However, consumables such as cutting tools, belts, and filters are usually excluded. Ensure the supplier provides a detailed written warranty document outlining what is included and any specific conditions for coverage.

- Warranty Duration: Most overseas CNC router suppliers offer a standard warranty of one year, although some may extend it to two or even three years for specific components. High-wear items like the spindle or inverter often come with shorter coverage, such as six months. A longer warranty period generally signals greater confidence in product quality, but it’s essential to verify the duration per component to avoid misunderstandings.

- Warranty Claim Process: Ask the supplier about the steps required, typically, this includes providing a description of the issue along with photos or videos. Clarify whether you must return the faulty part or if the supplier will send a replacement directly. Efficient suppliers often assist with remote diagnosis and may even cover local repair costs under certain conditions.

- Shipping and Replacement Costs: Determine who bears the shipping costs when warranty parts are replaced. Some suppliers offer free replacement parts but require the buyer to pay for international shipping, while others cover shipping for critical components during the warranty period. It’s also important to confirm whether the supplier will provide the necessary customs paperwork and support in case the parts need to be imported separately.

- Limitations and Exclusions: All warranties have limitations, and it’s important to read the fine print. Common exclusions include damage caused by improper installation, power surges, user error, or unauthorized modifications. Wear-and-tear on consumables and third-party software issues are also typically excluded. Understanding these exclusions in advance helps set realistic expectations and ensures you know how to properly maintain your machine to stay within warranty conditions.

A well-qualified CNC router supplier will not only provide a high-performing machine but also stand behind their product with strong support and service. Use these evaluation criteria as your checklist to identify trusted partners who can meet your production needs today and support your growth in the future.

Verify Technical Specifications and Build Quality

Ensuring that the CNC router you choose meets the required technical standards and is built with consistent manufacturing quality. Overseas suppliers often offer a wide range of models, so it’s your responsibility as a buyer to verify every detail before committing.

Review Technical Specifications in Detail

Carefully examine the machine’s core specifications and match them against your application needs. Key elements include:

- Spindle Power and Speed: Affects material compatibility and cutting efficiency.

- Drive System: Options like ball screw (high precision, slower speed) or rack and pinion (faster, suitable for larger tables) influence accuracy and performance.

- Motor Type: Stepper motors are cost-effective but less precise than servo motors, which offer better speed, torque, and positioning accuracy.

- Worktable Size and Z-axis Travel: Confirm dimensions align with your material size and part thickness requirements.

- Control System: Check for compatibility with software like Mach3, DSP, or NCStudio, and whether the interface is user-friendly and well-supported.

Request a full technical specification sheet from the supplier and ask questions about any unfamiliar terms or components.

Evaluate Build Quality and Frame Construction

The structure of the CNC router directly affects its durability, vibration resistance, and accuracy over time. Ask the supplier for information or videos showing:

- Frame Material: A heavy-duty welded steel frame or cast iron base reduces vibrations and ensures long-term stability.

- Assembly Precision: Look for tight tolerances, smooth gantry motion, and aligned guide rails.

- Linear Guides and Bearings: Components from recognized brands like HIWIN or PMI are signs of quality and ensure precise motion control.

- Cable Management and Wiring: Clean, shielded cabling, well-labeled connections, and organized control cabinets are signs of professional assembly.

You can also request high-resolution photos or videos of the machine in production, including close-ups of internal components and structural welds.

Evaluate Quality Control and Testing Procedures

A serious CNC router supplier will follow structured testing processes, provide transparent documentation, and hold industry certifications. Below is a breakdown of three essential areas to evaluate:

Factory Testing Before Shipment

Thorough factory testing is the final step in quality control before the CNC router is packed and shipped. This process ensures that every mechanical, electrical, and control component is fully functional. A professional supplier typically performs a Factory Acceptance Test (FAT), which includes:

- Full system operation: Running the CNC router through real cutting programs to test motion control, spindle function, and axis travel.

- Calibration checks: Ensure the machine’s gantry is square, the Z-axis is perpendicular, and the backlash is within acceptable limits.

- Spindle performance: Running the spindle at full RPM to check for unusual vibration or noise.

- Safety system testing: Verifying the emergency stop, limit switches, door sensors, and electrical protections.

- Software and controls: Testing responsiveness and compatibility of the control system, including loading G-code, toolpaths, and interface operation.

You should request confirmation that this testing is done for your specific unit—not just as a general factory routine.

Quality Assurance Certification

Quality assurance certifications serve as evidence that the supplier operates under recognized standards and adheres to a formalized quality management system. The most common and important certifications to look for include:

- ISO 9001: This is a global benchmark for quality management systems. A supplier certified under ISO 9001 follows standardized procedures for design, production, testing, and continuous improvement.

- CE Certification: This is necessary if you are importing into Europe. It indicates that the machine meets EU safety, health, and environmental protection requirements.

- SGS, TUV, or Intertek Reports: These third-party inspection agencies often perform independent factory audits and testing. Their involvement indicates higher transparency and accountability.

Ask the supplier for valid and up-to-date certificates, and verify their authenticity with the issuing body if needed.

Pre-Delivery Inspection Report or Video

A trustworthy supplier should be willing to provide a pre-delivery inspection report or a custom video showing your specific CNC router under testing. This step gives you direct visibility into the machine’s condition and functionality before it leaves the factory. A high-quality inspection package should include:

- Video demonstration: Showing your machine cutting actual material, homing axes, moving across the worktable, and operating the spindle.

- Photos of key components, including close-ups of the control cabinet, motors, drive system, cable management, and machine frame.

- Performance metrics: Measurements of accuracy, spindle runout, repeatability, and any adjustments made.

This final review step ensures transparency, allows you to verify quality remotely, and provides peace of mind before the machine is packaged and shipped.

Understand Shipping, Taxes, and Import Regulations

Buying a CNC router from an overseas supplier involves more than just the product price, it also includes shipping logistics, customs clearance, taxes, and local regulations. Understanding the full scope of international shipping and import procedures is beneficial for a smooth transaction.

Shipping Terms and Freight Options

Start by clarifying the shipping terms offered by the supplier. Common options include:

- FOB (Free on Board): The supplier handles costs until the machine is loaded at the port. From there, you’re responsible for freight, insurance, and customs.

- CIF (Cost, Insurance, and Freight): The supplier covers shipping and insurance to your port, but you still handle import duties and inland delivery.

- DDP (Delivered Duty Paid): The most convenient option, where the supplier handles everything, including customs clearance and delivery to your door. It’s more expensive but removes much of the complexity.

Ensure the supplier uses reliable freight forwarders and provides proper crating and packaging to prevent damage during transit.

Customs Duties and Import Taxes

Every country has its own tariff system, and CNC routers are typically subject to import duties, VAT/GST, and possibly handling fees. You should:

- Check the HS (Harmonized System) code your country assigns to CNC routers (usually around 8465.99).

- Use government websites or consult with a local customs broker to calculate duties and applicable taxes.

- Prepare for brokerage fees, which are charges from the logistics company handling customs clearance.

- Ensure you have all necessary documents: commercial invoice, packing list, bill of lading/airway bill, and certificates (e.g., CE, origin).

A good supplier will support you with accurate documentation and pre-fill forms to expedite the customs process.

Compliance with Local Import Regulations

Certain countries require that imported CNC machinery meet local safety, environmental, or electrical standards. Be sure to check:

- If a local electrical code requires modifications (e.g., voltage conversion, plug types)

- Whether a national registration or inspection is needed before using the equipment

- If the machine must pass a conformity assessment (especially common in Europe or the Middle East)

- If your facility needs to be prepared with proper ventilation, grounding, or space clearance for legal installation

Suppliers familiar with exporting to your country will often have versions of the machine designed to meet local standards.

Estimated Delivery Time and Logistics Planning

Shipping a CNC router internationally typically takes anywhere from 2 to 8 weeks, depending on production time, transport method, and customs clearance efficiency. Plan your schedule accordingly by asking:

- What is the production lead time before shipping?

- Is the machine shipped via ocean freight (cheaper, slower) or air freight (faster, costlier)?

- Are there holidays or port delays in either country that might affect your timeline?

Factor in time for installation, testing, and training once the machine arrives.

Understanding the full logistics chain will help you avoid costly surprises and delays. Work closely with both your CNC router supplier and a local customs broker to ensure all documents are in order and your machine clears customs smoothly. A reliable supplier will guide you through this process and ensure your CNC router arrives safely, legally, and ready for use.

Assess Total Cost of Ownership (TCO)

When evaluating the cost of a CNC router from an overseas supplier, it’s crucial to look beyond the initial purchase price. The total cost of ownership (TCO) includes all the direct and indirect expenses associated with acquiring, operating, and maintaining the machine throughout its lifespan.

- Machine Cost and Optional Features: The base price of the CNC router is just the starting point. Many suppliers offer optional add-ons such as vacuum tables, rotary axes, dust collection systems, and automatic tool changers. While these features may increase the initial cost, they can significantly boost productivity and reduce labor. Be sure to compare machines with equivalent configurations to make a fair cost comparison.

- Shipping, Customs, and Tax Fees: International shipping can add thousands of dollars to your final bill, depending on the machine size, weight, and destination. Add to this the import duties, VAT/GST, brokerage fees, and inland transportation costs. Ensure you understand whether your quoted price includes FOB, CIF, or DDP terms, and request an itemized cost breakdown from your supplier or freight forwarder.

- Installation, Setup, and Training: Costs for setup and training are often underestimated. If the supplier doesn’t include onsite installation, you may need to hire local technicians or spend time and resources training staff remotely. Some suppliers provide free training, others may charge extra.

- Operating Costs: Operating expenses include electricity consumption, tool wear, maintenance materials, and consumables. High-power spindles and servo motors may provide better performance but can increase energy bills. Also, factor in software licenses or updates if the control system requires paid platforms.

- Maintenance and Downtime Risk: Check if spare parts are easily available and reasonably priced. Unexpected breakdowns can lead to long production delays, especially if replacement parts need to be shipped from overseas. A machine with good after-sales support and simple maintenance procedures will save costs over time.

- Warranty, Support, and Longevity: A longer, more comprehensive warranty can lower your TCO by reducing repair costs in the early years. Machines built with branded, high-quality components often last longer and require fewer replacements. Evaluate the supplier’s reputation for long-term reliability and technical support availability.

The total cost of ownership gives you a more accurate picture of the true investment required for your CNC router. By considering all costs, you can make smarter comparisons and choose a machine that offers the best value over time. Always ask suppliers for complete cost transparency, and weigh both short-term savings and long-term performance when making your decision.

Summarize

Buying a CNC router from an overseas supplier can be a cost-effective and rewarding investment if approached with careful planning and due diligence. Don’t be swayed by price alone, focus on the overall value, reliability, support, and performance the supplier can deliver. A trustworthy partner will not only provide a well-built machine but also offer the after-sales support and guidance you need to keep your operation running smoothly. By taking the time to evaluate each factor thoroughly, you can make a confident decision that supports your productivity and growth for years to come. For further insights, refer to our “Choosing CNC Router Manufacturer: A Comprehensive Guide”.

If you’re considering purchasing a CNC router from an overseas supplier, AccTek CNC stands out as a trusted choice. As a professional CNC router manufacturer based in China, we combine years of industry experience with a strong commitment to quality, performance, and customer satisfaction. With a reputation built on delivering high-performance machines and excellent customer service, AccTek CNC is a dependable partner for businesses seeking a cost-effective and long-lasting CNC router solution from an overseas manufacturer.