- 12-17 Min Read

In the world of Computer Numerical Control (CNC) machining, precision and efficiency determine product quality and output. At the heart of this technology lies the spindle, a component responsible for rotating cutting tools, thus shaping raw materials into intricate designs with utmost accuracy. From wood and plastics to metals and composites, different materials necessitate varying spindle speeds to achieve desired cutting results while ensuring tool longevity and surface finish. So understanding the spindle speed range and its implications is beneficial for achieving optimal performance and desired outcomes in CNC machining.

This article delves into the intricacies of spindle speed ranges in CNC routers, exploring their significance, factors influencing selection, and the impact on machining operations. Whether you’re a seasoned CNC operator, a hobbyist exploring the realm of computerized machining, or an industry professional seeking to enhance efficiency, this guide aims to provide clarity and insights into optimizing spindle speeds for diverse applications.

The Importance of Spindle Speed in CNC Routing

- The spindle speed of a CNC router refers to the rotational velocity at which the spindle, the component responsible for holding and rotating cutting tools, operates during machining operations. It is a crucial factor in CNC routing as it directly affects the quality, efficiency, and precision of the machining process. The importance of spindle speed in CNC routing is reflected in the following aspects:

- Tool Life and Wear: Spindle speed influences the wear and tear on cutting tools. Proper spindle speed selection can extend tool life by reducing excessive heat buildup and friction. Higher speeds might cause tools to wear out faster, while lower speeds might result in slower cutting rates but longer tool life.

- Surface Finish: The spindle speed affects the surface finish of the machined part. Optimal speeds ensure smoother finishes, reducing the need for additional finishing operations. Higher spindle speeds often result in finer surface finishes due to reduced tool chatter and smoother cutting action.

- Material Removal Rate: The spindle speed, combined with feed rate, determines the material removal rate. Higher spindle speeds can lead to faster material removal rates, which is important for efficiency in production environments. However, this must be balanced with tool life and the machine’s capabilities.

- Chip Formation: Spindle speed influences chip formation during machining. Improper speeds can lead to issues like chip recutting, chip welding, or poor chip evacuation, which can compromise surface finish and dimensional accuracy.

- Tool Chatter and Vibrations: The spindle speed affects tool chatter and vibrations during machining. Operating at incorrect speeds can lead to resonance, causing poor surface finish, dimensional inaccuracies, and potential damage to the machine or workpiece.

- Tool Diameter and Material Compatibility: Different materials and tool diameters require different spindle speeds for optimal performance. Harder materials typically require lower spindle speeds to prevent excessive tool wear and breakage, while softer materials may benefit from higher spindle speeds for efficient cutting.

- Precision and Accuracy: Maintaining consistent spindle speeds is more beneficial for achieving precise and accurate cuts. Variations in spindle speed can lead to dimensional inaccuracies and variations in part quality.

- Tool Selection: Spindle speed influences the selection of cutting tools. Different types of tools are designed to operate optimally within specific speed ranges. Choosing the appropriate tool and spindle speed for the job ensures efficient material removal and prolongs tool life.

Understand The Spindle Speed Range

In the context of CNC routers, the spindle speed range refers to the range of rotational speeds at which the machine’s spindle can operate effectively. The spindle speed range is determined by the specifications of the CNC router’s spindle motor, transmission mechanisms, and the capabilities of the CNC control system. It typically encompasses a range of RPM values, from a minimum to a maximum, within which the spindle can rotate while maintaining stability, precision, and efficiency during machining operations. Let’s take a more detailed look at it next.

Relationship with RPM

RPM (Revolutions Per Minute) is a measure of the spindle’s rotational speed and is a key parameter in CNC machining. The spindle speed range directly correlates with RPM and defines the permissible RPM values that the CNC router’s spindle can achieve. CNC operators adjust the spindle speed within its range based on factors such as the material being machined, the type and size of the cutting tool, the desired surface finish, and the specific requirements of the machining operation.

Lower RPM values within the spindle speed range are suitable for tasks such as rough cutting, heavy material removal, or machining harder materials. Slower speeds can help prevent tool breakage, reduce heat generation, and enhance cutting tool longevity. Higher RPM values in the spindle speed range are utilized for tasks such as finishing cuts, detailed engraving, or machining softer materials. Higher speeds can result in smoother surface finishes, finer detail resolution, and faster cutting rates for certain materials and cutting tools.

Variable Speed Spindle System

Many CNC routers are equipped with variable speed spindle systems, allowing operators to dynamically adjust the spindle speed within the specified range during machining processes. These variable speed systems provide flexibility and control over the machining operation, enabling CNC operators to optimize spindle speed for enhanced machining performance and quality.

Variable speed spindle systems in CNC routers are typically driven by spindle motors controlled by the CNC machine’s software. The software allows operators to set and adjust the spindle speed either manually or automatically based on programmed parameters. Variable speed spindle systems may utilize technologies such as frequency inverters, variable frequency drives (VFDs), or electronic speed controllers to regulate the spindle motor’s speed. By optimizing spindle speed based on factors such as feed rate, tool geometry, material properties, and cutting conditions, variable speed spindle systems help enhance machining efficiency, surface finish quality, and overall productivity in CNC routing applications.

Factors affecting spindle speed

Several factors influence the spindle speed of a CNC router, affecting the choice of RPM for different machining operations. By considering these factors and experimenting with different spindle speed settings, CNC operators can optimize machining parameters for each specific application, resulting in improved efficiency, surface finish quality, and tool longevity. Here are some key factors:

Material Type

- Hardness and Density: Harder materials like metals generally require lower spindle speeds to prevent tool wear and overheating. Softer materials like wood or plastics may tolerate higher spindle speeds for faster cutting speeds.

- Thermal Conductivity: Materials with high thermal conductivity dissipate heat more effectively, allowing for higher spindle speeds without excessive heat buildup.

- Brittleness: Brittle materials may require lower spindle speeds to prevent tool breakage, especially during milling or routing operations.

Cutting Tool Specifications

- Tool Diameter: Larger diameter tools may require lower spindle speeds to maintain cutting stability and prevent tool deflection, while smaller diameter tools can handle higher spindle speeds for finer detail work.

- Tool Material and Coating: The material composition and surface coatings of cutting tools impact their heat resistance and cutting performance. Tools made from high-speed steel (HSS), carbide, or diamond-coated materials have different optimal speed ranges. Some coatings increase tool lifespan and reduce friction, allowing for higher RPM without compromising cutting performance.

- Tool Geometry: Tool geometry, including flute design and rake angle, influences chip evacuation and cutting forces, affecting the optimal spindle speed for efficient machining.

Machining Operations

- Depth of Cut: The depth of cut (DOC) refers to the thickness of material removed in a single pass. Deeper cuts generally require lower RPM to reduce cutting forces and prevent tool overload. Shallower cuts may allow for higher RPM to maintain efficiency and surface finish quality.

- Feed Rate: The feed rate is the speed at which the cutting tool moves through the material during machining. Higher feed rates often necessitate higher spindle speeds to maintain chip load and cutting efficiency. Conversely, lower feed rates may allow for lower spindle speeds while still achieving desired cutting results.

- Tool Path Complexity: Complex tool paths with intricate geometries or tight corners may require adjustments to spindle speed to maintain cutting accuracy and prevent tool breakage. CNC programming software often provides options to optimize spindle speed based on tool path complexity and geometry.

CNC Router Specifications

- Machine Rigidity: The rigidity and stability of the CNC router machine affect its ability to handle high spindle speeds. More rigid machines can often tolerate higher RPM without compromising cutting accuracy or causing excessive vibration.

- Spindle Motor Power: The power of the spindle motor determines the maximum achievable spindle speed and the range of materials and cutting operations the CNC router can handle effectively.

- Spindle Speed Range: The design and capabilities of the CNC router’s spindle system define the range of spindle speeds available for different machining tasks. Variable speed spindle systems provide flexibility in adjusting spindle speed based on material type and cutting requirements.

Effect of spindle speed on cutting quality

The spindle speed of a CNC router has a profound impact on determining the cutting quality and overall machining performance. Balancing these factors and selecting the optimal spindle speed for each machining operation is beneficial to achieve high-quality results and maximize productivity. Here’s how spindle speed influences cutting quality:

- Surface Finish: Spindle speed directly affects the surface finish of the machined part. Higher spindle speeds typically result in smoother surface finishes due to reduced chip size and improved chip evacuation. However, excessively high spindle speeds may cause vibrations or chatter, leading to surface imperfections. Finding the optimal spindle speed for each material and cutting operation is beneficial to achieve the desired surface finish.

- Edge Quality: Proper spindle speed selection contributes to achieving clean and sharp edges on machined parts. Optimal spindle speeds help prevent edge burrs or fraying, resulting in higher edge quality. Lower spindle speeds may produce cleaner edges in some materials, especially when cutting through thicker sections or brittle materials.

- Dimensional Accuracy: Spindle speed affects dimensional accuracy by influencing tool deflection and cutting forces during machining. Higher spindle speeds can reduce deflection and improve dimensional accuracy, particularly in fine detail work. However, you need to ensure that the spindle speed does not cause tool chatter or resonance, which could lead to dimensional inaccuracies.

- Tool Life: The choice of spindle speed significantly impacts tool life and cutting tool wear. Optimal spindle speeds help minimize tool wear by maintaining proper chip formation and reducing friction between the tool and the workpiece. Excessive spindle speeds may accelerate tool wear and lead to premature tool failure, while insufficient speeds can cause tool overheating and degradation.

- Material Removal Rate: Spindle speed influences the material removal rate (MRR) during machining operations. Higher spindle speeds typically result in faster material removal rates due to increased cutting efficiency. However, the relationship between spindle speed and MRR is not linear, and other factors such as feed rate and depth of cut also play significant roles in determining the overall material removal rate.

- Chip Evacuation: Proper spindle speed selection aids in effective chip evacuation, which is beneficial for maintaining cutting efficiency and preventing chip recutting. Higher spindle speeds often produce smaller, more manageable chips that are easier to evacuate from the cutting zone, reducing the risk of chip buildup and tool damage.

Effect of spindle speed on different materials

The influence of CNC router spindle speed varies depending on the material being machined. Different materials have distinct properties that affect how they respond to cutting processes at different spindle speeds. Here’s how spindle speed influences cutting performance and quality for various materials commonly processed on CNC routers:

Wood

Optimal Speed for Different Wood Types

- Softwoods (e.g., pine, cedar): Softwoods generally respond well to higher spindle speeds. Optimal speeds for softwoods typically range from moderate to high, allowing for faster cutting rates and smoother surface finishes. However, excessively high speeds may lead to burning or charring, especially in resin-rich woods like pine.

- Hardwoods (e.g., oak, maple): Hardwoods are denser and require more attention to spindle speed selection. Optimal speeds for hardwoods typically range from low to moderate to minimize tool wear and prevent burning. Slower speeds help control cutting forces and reduce the risk of tear-out or chipping.

Impact on Surface Finish

- Higher Spindle Speeds: Increasing spindle speed tends to improve surface finish by producing smaller, more manageable wood chips and reducing cutting resistance. Smoother surface finishes are often achieved at higher spindle speeds due to reduced chip size and improved chip evacuation. However, care must be taken to avoid overheating or burning the wood, especially at excessively high speeds.

- Lower Spindle Speeds: Lower spindle speeds may result in rougher surface finishes due to larger chip sizes and increased cutting forces. However, slower speeds are sometimes preferred for achieving specific textural effects or minimizing tear-out on highly figured wood grain.

Impact on Material Integrity

- Higher Spindle Speeds: Excessively high spindle speeds can compromise the integrity of the wood, leading to burning, charring, or heat-induced stress. Care must be taken to balance cutting efficiency with material integrity, especially in denser or resinous woods that are more prone to burning.

- Lower Spindle Speeds: Lower spindle speeds generally pose less risk to material integrity but may result in slower cutting rates and increased tool wear. For delicate workpieces or intricate designs, slower speeds are often preferred to maintain material integrity.

Metal

Optimal Speed for Different Metal Types

- Aluminum: Aluminum is commonly machined at moderate to high spindle speeds. Higher speeds help prevent built-up edge formation and improve chip evacuation. However, excessively high speeds may cause tool wear or chatter, so an optimal balance needs to be found.

- Steel (e.g., Mild Steel): Mild steel is often machined at lower to moderate spindle speeds to maintain cutting stability and prevent tool wear. Higher speeds may result in reduced tool life and poor surface finish.

- Brass and Copper: Similar to aluminum, brass, and copper are machined at moderate to high spindle speeds. Because these materials are more prone to work hardening, proper cooling and chip evacuation are required.

Impact on Chip Formation

- Higher Spindle Speeds: Higher spindle speeds generally result in smaller, more manageable chips. This is beneficial for chip evacuation and can help prevent chip recutting, leading to improved surface finish and dimensional accuracy.

- Lower Spindle Speeds: Lower spindle speeds may produce larger chips, which can be advantageous for certain machining operations, such as heavy roughing cuts. However, care must be taken to ensure effective chip evacuation to prevent chip buildup and tool damage.

Effect on Heat Production

- Higher Spindle Speeds: Higher spindle speeds can lead to increased heat generation due to higher cutting speeds and friction between the tool and the workpiece. Proper cooling methods, such as using coolant or air blast, are beneficial to dissipate heat and prevent thermal damage to the workpiece and cutting tool.

- Lower Spindle Speeds: Lower spindle speeds typically result in less heat generation compared to higher speeds. This can be advantageous for materials that are prone to thermal damage or when machining operations require tighter tolerances and dimensional stability.

Plastic

Optimal Speed for Different Plastic Types

- Acrylic (PMMA): Acrylic is commonly machined at moderate to high spindle speeds. Optimal speeds allow for efficient material removal and clean cuts, resulting in polished edges and smooth surface finishes. However, care must be taken to prevent melting, especially at higher speeds.

- HDPE (High-Density Polyethylene): HDPE responds well to lower to moderate spindle speeds. Slower speeds help control heat buildup and prevent melting or deformation of the plastic. However, cutting efficiency may be reduced compared to higher spindle speeds.

- Polycarbonate (PC): Polycarbonate is typically machined at moderate spindle speeds. Optimal speeds balance cutting efficiency with heat generation, minimizing the risk of melting or surface defects. Lower speeds may be necessary for thicker or more complex parts to prevent overheating.

Avoiding Melting and Deformation

- Coolant and Lubrication: Using coolant or lubricants during machining helps dissipate heat and reduce friction between the cutting tool and the plastic surface. Proper coolant application can help lower temperatures and prevent melting or deformation, especially at higher spindle speeds.

- Chip Evacuation: Effective chip evacuation prevents chip buildup and recutting, which can contribute to heat buildup and material deformation. Proper chip evacuation systems ensure that chips are removed from the cutting zone efficiently, reducing the risk of melting or surface defects.

- Tool Selection: Choosing the right cutting tools with appropriate geometries, coatings, and sharpness is beneficial for minimizing heat generation and preventing plastic deformation. Tools specifically designed for plastics help achieve cleaner cuts and smoother surface finishes while reducing the risk of melting or chipping.

- Feed Rate Control: Controlling the feed rate along with spindle speed is important for managing heat generation during machining. Adjusting the feed rate can help maintain chip size and evacuation, reducing the risk of heat buildup and material deformation, especially in thermally sensitive plastics.

Composite Materials

Optimal Speed

The optimal spindle speed for machining composite materials depends on various factors such as the type of composite, its constituents, tool material, and cutting conditions. Generally, a higher spindle speed is preferred for machining composites like carbon fiber reinforced plastics (CFRP) or fiberglass composites. This is because higher speeds can help reduce cutting forces, minimize delamination, and achieve better surface finish. However, the optimal speed should be determined experimentally considering factors such as tool wear, heat generation, and material properties.

Balanced Cutting Efficiency

Spindle speed influences the cutting efficiency when machining composites. It’s essential to find a balance between cutting speed and feed rate to ensure efficient material removal without causing excessive tool wear or damage to the workpiece. Adjusting the spindle speed appropriately can help achieve this balance. For instance, lower spindle speeds might be suitable for tougher composite materials to prevent overheating and tool degradation, while higher spindle speeds can be employed for softer composites to improve material removal rates.

Fine Machining

Fine machining involves achieving high precision and surface quality in the machined part. Spindle speed plays a significant role in fine machining of composite materials. Lower spindle speeds combined with smaller feed rates are often used for finishing operations to achieve finer surface finishes and dimensional accuracy. Fine machining requires careful control of cutting parameters, including spindle speed, to minimize tool deflection and vibration, which can negatively impact surface quality.

Effect of Spindle Speed on Cutting Tools

Spindle speed has a significant impact on cutting tools in CNC machining. Finding the optimal spindle speed involves balancing tool life, cutting quality, and surface finish considerations. By carefully adjusting spindle speed based on material type, tooling, and desired machining outcomes, manufacturers can optimize tool performance, enhance cutting quality, and achieve superior surface finishes in CNC routing operations. The following is a detailed introduction:

Tool Life and Wear

Spindle speed directly influences the wear rate and, consequently, the overall lifespan of cutting tools. Higher spindle speeds lead to increased cutting speeds, which can accelerate tool wear, particularly at the cutting edges. Excessive wear shortens tool life, necessitating more frequent tool changes. This increases downtime for tool replacement and raises tooling costs. Conversely, lower spindle speeds reduce cutting speeds and associated friction and heat generation, thereby decreasing wear on cutting tools and extending their lifespan. Finding the optimal spindle speed helps balance tool wear and cutting efficiency.

Cutting Quality

Optimal spindle speeds contribute to better cutting quality by ensuring stable cutting conditions. Maintaining the appropriate spindle speed helps minimize tool deflection and vibration, resulting in precise and accurate cuts. Spindle speed also affects chip formation and evacuation. Proper chip formation prevents chip recutting, which can lead to poor cutting quality and surface defects. Incorrect spindle speeds can result in issues such as surface defects, dimensional inaccuracies, and edge chipping, especially when machining harder or more abrasive materials.

Surface Finish

Higher spindle speeds can result in smoother surface finishes due to reduced tool vibrations and better chip evacuation. This is particularly advantageous for applications requiring high precision and aesthetics, where a fine surface finish is desired. However, excessively high spindle speeds may lead to surface defects such as tool marks, chatter, or burn marks. Conversely, lower spindle speeds may be necessary for achieving specific surface finish requirements, especially in softer or more delicate materials.

Summarize

In essence, the spindle speed range of a CNC router serves as a critical parameter that empowers operators to achieve desired outcomes in terms of accuracy, surface finish, and efficiency. A thorough comprehension of the spindle speed range enables operators to adapt to various materials, cutting tasks, and machining requirements effectively. Whether it’s milling, drilling, engraving, or routing, the ability to adjust spindle speeds allows for versatility and precision in CNC machining applications. By leveraging the full potential of the CNC router’s spindle speed range, manufacturers and machinists can meet the demands of modern manufacturing with confidence and precision.

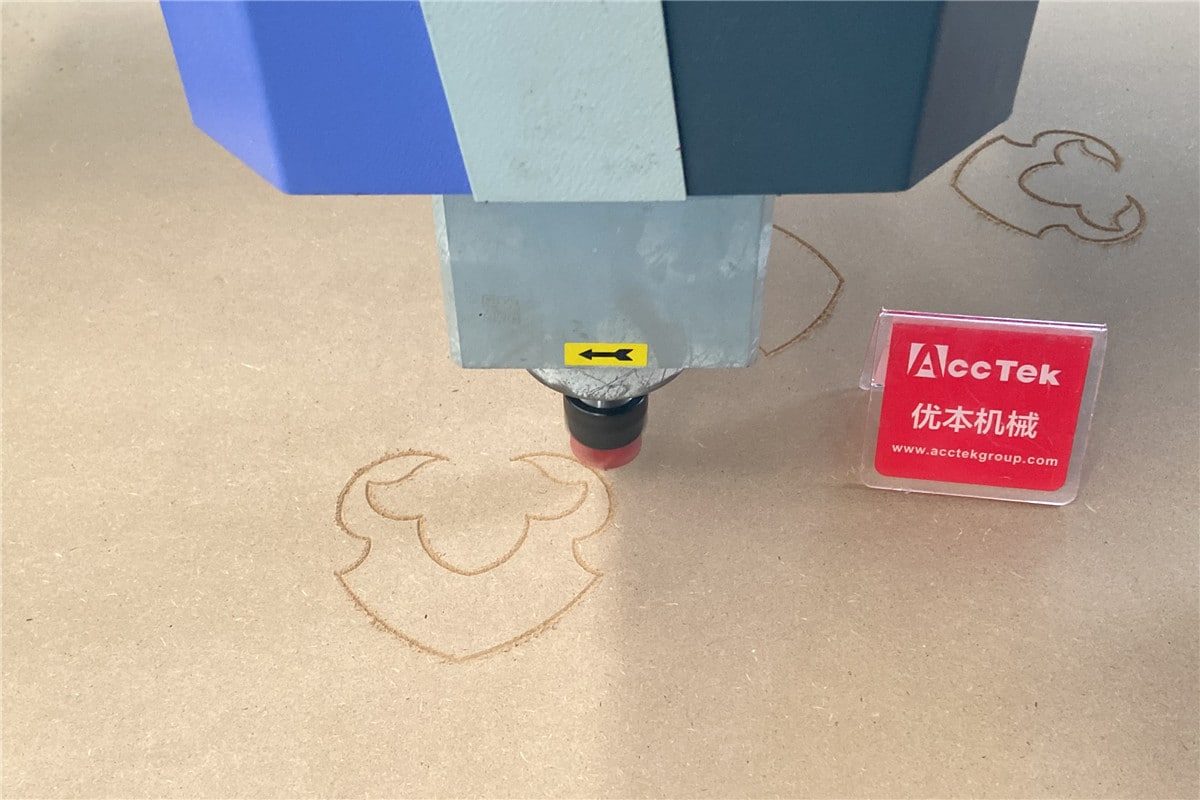

In the dynamic landscape of modern industry, the utilization of CNC technology is not merely advantageous but often beneficial for businesses striving to maintain a competitive edge. AccTek CNC offers you a comprehensive array of CNC routers tailored to diverse production requirements. From the fundamental 3-axis systems to the intricate capabilities of 4-axis and 5-axis machines, AccTek CNC ensures that enterprises can harness the power of CNC routing to propel their operations forward. Contact us to start your CNC router plan.