What Are The Factors That Affect The Life of CNC Router Bit?

- 6-10 Min Read

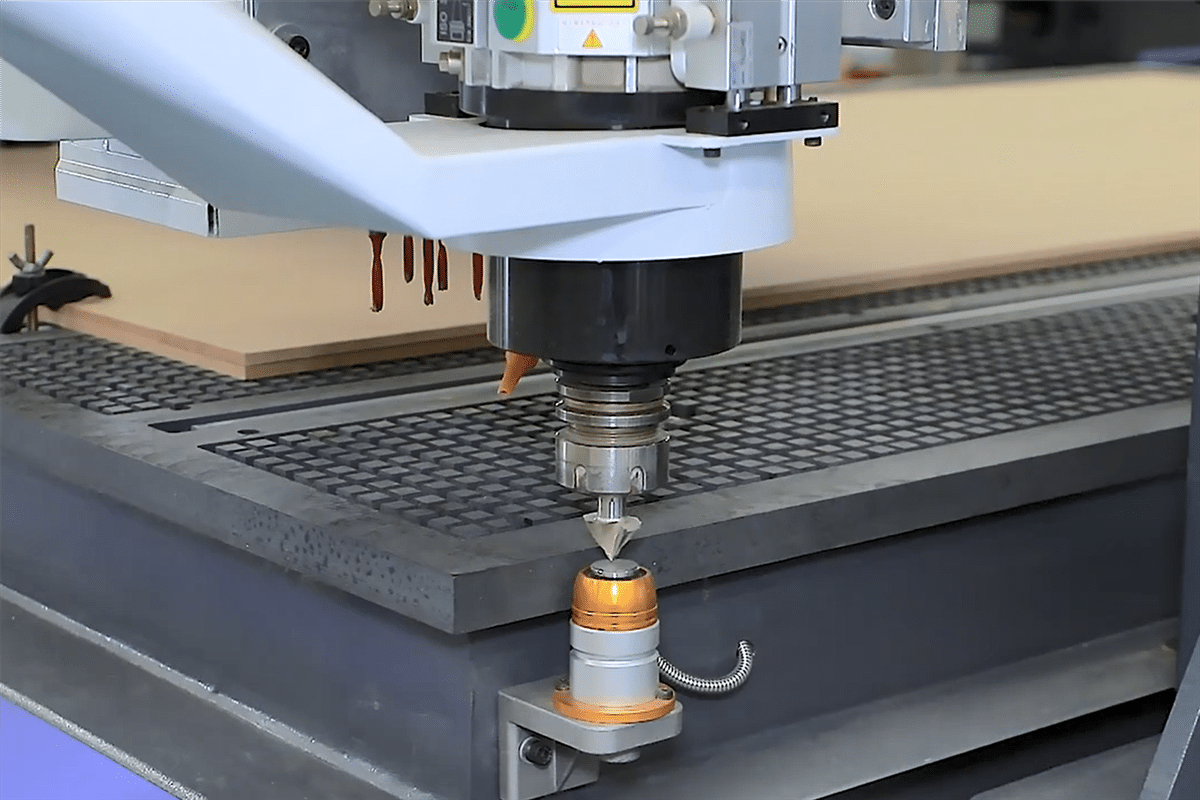

The efficiency and longevity of a CNC router bit are pivotal factors in ensuring the smooth operation and quality output of computer numerical control (CNC) machining processes. From carving intricate designs to shaping robust materials, CNC router bits play a key role in various industries, including woodworking, metalworking, and manufacturing. However, like any tool, the lifespan of a CNC router bit depends on several key factors that influence its durability and performance. Understanding these factors is beneficial for maximizing productivity, minimizing downtime, and achieving optimal results in CNC machining operations. In this article, we delve into the factors that significantly impact the life expectancy of CNC router bits, offering insights into maintenance practices, material considerations, and operational strategies to prolong their lifespan and enhance machining efficiency.

The Importance of Extending The Life of CNC Router Bits

The importance of prolonging the lifespan of CNC router bits reverberates across various critical aspects of machining operations. From cost efficiency to productivity, and the quality of finished products to sustainability concerns, the benefits of maximizing the longevity of router bits are manifold. In this section, we explain the multifaceted significance of extending the life of CNC router bits, emphasizing its importance in terms of processing performance, economic feasibility, and environmental sustainability.

- Cost Efficiency: CNC router bits can be expensive, especially high-quality ones made of durable materials like carbide. By prolonging their lifespan, businesses can reduce the frequency of replacements, thereby lowering overall operating costs. This cost efficiency becomes particularly significant in industries with high-volume production requirements, where the savings from extended tool life can be substantial over time.

- Enhanced Productivity: When CNC router bits maintain their sharpness and precision for longer durations, machining operations can run smoothly without interruptions for tool changes. This uninterrupted workflow leads to increased productivity as machines can operate continuously, completing more tasks within the same timeframe. Minimizing downtime for tool replacement or sharpening also improves overall efficiency and output consistency.

- Consistent Quality: A worn-out or damaged router bit can compromise the quality of machined parts or products. Maintaining sharp and properly functioning bits ensures consistent surface finishes, accurate dimensions, and precise detailing, which are beneficial for meeting quality standards and customer expectations. Consistency in machining quality also reduces the need for rework or scrap, saving both time and materials.

- Operator Safety: Worn-out router bits are more prone to breakage or malfunction during operation, posing safety risks to machine operators and surrounding personnel. By extending the life of CNC router bits, businesses prioritize the safety of their workforce, minimizing the likelihood of accidents or injuries associated with tool failure. This commitment to safety not only protects personnel but also contributes to a positive work environment and regulatory compliance.

- Environmental Sustainability: Extending the lifespan of CNC router bits aligns with sustainability goals by reducing the consumption of raw materials and energy required for manufacturing new tools. By maximizing the utility of existing resources, businesses can minimize their environmental footprint and contribute to resource conservation efforts. Additionally, reducing the disposal of worn-out tools decreases waste generation and promotes responsible waste management practices within the manufacturing sector.

Key Factors Affecting Router Bit Life

The lifespan of router bits is influenced by various factors that encompass not only the tool itself but also the machining environment and operator practices. Here’s an introduction to the key factors affecting router bit life from different perspectives:

- Router Bit Material: The material composition of the router bit significantly affects its wear resistance and overall durability. Bits made from high-quality materials like carbide exhibit superior hardness and toughness, leading to extended tool life compared to bits made from lower-grade materials.

- Router Bit Coating Type: Coatings such as TiN, TiCN, or TiAlN provide additional protection to the router bit’s cutting edges, reducing friction, heat buildup, and wear during machining. The choice of coating depends on the specific application and material being cut, with each type offering varying degrees of durability and performance enhancement.

- Bit Slot Design: The design of the router bit’s flutes or slots plays a role in chip evacuation and heat dissipation. Proper flute design facilitates efficient chip removal, reducing the risk of chip recutting and heat accumulation, which can contribute to premature wear and tool failure.

- Edge Sharpness and Angle: The sharpness and cutting angle of the router bit’s edges directly influence cutting efficiency and tool life. Sharper edges and optimal cutting angles result in reduced cutting forces, lower friction, and less heat generation, prolonging the lifespan of the tool.

- Feed Rate: Maintaining an appropriate feed rate relative to the cutting parameters and material properties is beneficial for maximizing the router bit lifespan. Excessive feed rates can lead to accelerated wear and tool damage, while insufficient feed rates may cause rubbing and overheating, also shortening tool life.

- Speed: Matching spindle speed (RPM) with the chosen feed rate is beneficial for achieving optimal cutting conditions. Proper speed-feed combinations ensure efficient chip formation, adequate tool engagement, and minimal heat generation, all of which contribute to extended router bit lifespan.

- The Hardness of Processed Materials: Harder materials require lower cutting speeds and feed rates to prevent excessive tool wear. Adjusting machining parameters according to material hardness helps maintain cutting edge integrity and prolong tool life when working with challenging materials.

- Wear Resistance of Processed Materials: Materials with high wear resistance, such as hardened steels or abrasive composites, pose additional challenges to tool longevity. Choosing router bits with appropriate coatings and geometry designed for wear resistance can mitigate tool wear and extend tool life when machining these materials.

- Cutting Depth and Stepover: The cutting depth and stepover, determine the amount of material removed in each pass and the distance between adjacent passes, respectively. Optimizing these parameters helps prevent excessive tool wear and prolongs the lifespan of the router bit by reducing cutting forces and heat generation.

- Tool Path Strategy: The choice of tool path strategy, such as conventional milling, climb milling, or adaptive machining, influences the distribution of cutting forces and the engagement of the router bit with the material. Selecting an appropriate tool path strategy helps minimize tool wear and maintain cutting edge integrity, thereby extending the router bit’s lifespan.

- Tool Path Simulation and Verification: Utilizing software simulations and verification tools allows machinists to analyze and optimize tool paths before actual machining operations. By identifying potential issues such as tool deflection, excessive wear, or collisions, tool path simulation helps mitigate risks and maximize router bit longevity.

- Cooling and Lubrication: Proper cooling and lubrication methods, such as using coolant or cutting fluids, are beneficial for dissipating heat, reducing friction, and preventing chip buildup during machining. Effective cooling and lubrication help maintain cutting edge sharpness and integrity, contributing to extended router bit life.

- Tool Inspection and Maintenance: Regular inspection and maintenance of router bits are key for detecting signs of wear, damage, or dullness early on. Implementing a proactive maintenance routine, including sharpening or replacing worn-out bits, helps prevent premature failure and extends the overall lifespan of the router bit.

- Operator Training: Adequate training and proficiency in operating CNC machines, selecting cutting parameters, and maintaining tooling are beneficial for optimizing router bit performance and longevity. Well-trained operators can make informed decisions to minimize tool wear and maximize efficiency during machining operations.

- Environmental Conditions: Factors such as temperature, humidity, cleanliness, and vibration levels in the machining environment can impact router bit performance and lifespan. Maintaining stable environmental conditions and implementing proper machine setup and maintenance practices help ensure consistent and reliable operation, thereby prolonging router bit life.

By addressing these key factors systematically and proactively, machinists can significantly enhance the lifespan and performance of CNC router bits, leading to greater efficiency, cost savings, and overall quality in machining operations.

The Role of Record Keeping and Documentation

Record keeping and documentation are essential tools for optimizing router bit performance, minimizing downtime, and maximizing tool longevity in CNC machining operations. Here’s how record keeping and documentation contribute to maximizing router bit lifespan:

- Maintenance History: Keeping detailed records of router bit usage, maintenance activities, and performance evaluations allows machinists to track the history of each tool. By documenting when a router bit was last sharpened, inspected, or replaced, operators can anticipate maintenance needs and schedule preventive actions to prevent premature failure and extend tool life.

- Tool Performance Analysis: Recording data on tool performance, such as cutting parameters, cutting times, and tool wear patterns, enables machinists to analyze trends and identify factors that may be contributing to accelerated wear or reduced efficiency. By analyzing performance data, operators can adjust machining parameters, tool paths, or material handling practices to optimize tool life and performance.

- Failure Analysis: In the event of router bit failure or suboptimal performance, documentation can aid in conducting thorough failure analysis investigations. Recording details such as the nature of the failure, machining conditions, and material properties helps identify root causes and implement corrective actions to prevent recurrence, ultimately improving router bit longevity.

- Tool Replacement Planning: Maintaining accurate records of router bit usage and wear progression allows machinists to predict when a tool is approaching the end of its usable life. By proactively planning for tool replacement based on historical data and wear trends, operators can minimize unplanned downtime, optimize inventory management, and ensure uninterrupted production.

- Training and Knowledge Transfer: Comprehensive documentation serves as a valuable resource for training new operators and transferring knowledge within the organization. By documenting best practices, troubleshooting techniques, and lessons learned from previous experiences, operators can leverage institutional knowledge to maximize router bit longevity and efficiency across shifts and personnel changes.

- Continuous Improvement: Documenting router bit usage, maintenance practices, and performance metrics supports ongoing improvement initiatives. By analyzing historical data and identifying opportunities for optimization, operators can implement incremental changes to machining processes, tooling selection, and maintenance procedures to continuously enhance router bit lifespan and overall productivity.

By leveraging historical data and institutional knowledge, operators can make informed decisions, implement proactive maintenance strategies, and drive continuous improvement efforts to achieve optimal results and extend the life of CNC router bits.

Summarize

The lifespan of CNC router bits is not solely determined by one factor but is rather influenced by a combination of factors. Maximizing the lifespan of CNC router bits requires a holistic approach that integrates technical expertise, proactive maintenance, and a commitment to excellence in machining operations. By prioritizing router bit longevity and investing in the necessary resources and practices, manufacturers can enhance their competitiveness and achieve greater success in today’s dynamic manufacturing landscape.

AccTek CNC offers a comprehensive range of CNC routers, including 3-axis, 4-axis, and 5-axis configurations to meet the diverse needs of modern machining operations. Whether for woodworking, metalworking, signage production, or other industrial applications, our CNC routers are renowned for their versatility, efficiency, and precision. In an era defined by rapid technological advancement and evolving manufacturing demands, AccTek CNC remains steadfast in its mission to empower users with the right CNC router solutions that drive innovation, efficiency, and success.