- 9-13 Min Read

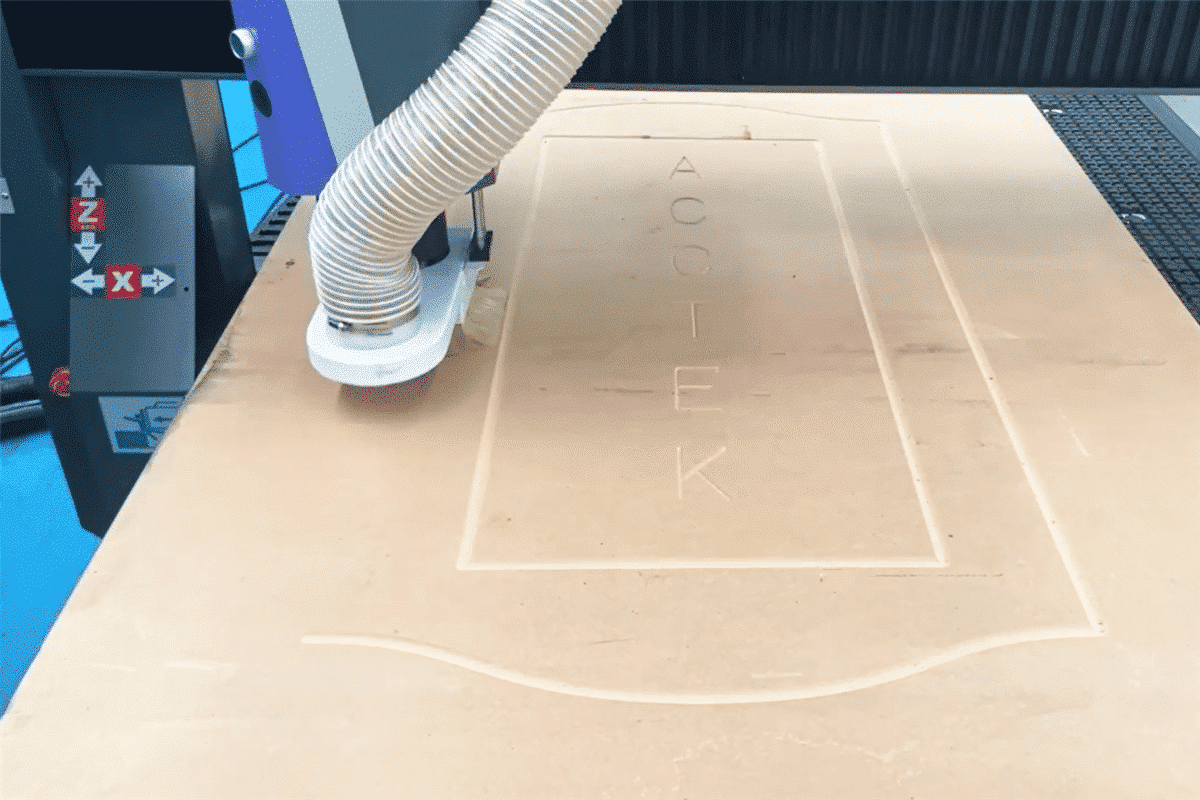

A wood CNC router is a versatile equipment used in woodworking that automates the cutting, carving, and shaping of wood materials with precision and efficiency. Whether used by large-scale manufacturers or individual craftsmen, wood CNC routers have become an essential tool for efficiently creating complex designs and intricate patterns that would otherwise take significantly more time and skill using traditional methods. Their ability to handle a wide range of wood materials makes them a popular choice for everything from furniture production to detailed decorative work.

However, despite these advantages, wood CNC routers also come with certain disadvantages. The initial cost of acquiring the machine, the learning curve associated with operating it, and ongoing maintenance are some of the challenges users may face. Additionally, CNC routers can require a substantial amount of space in a workshop, and the complexity of programming may pose difficulties for beginners. In this article, we will delve into both the benefits and drawbacks of using a wood CNC router, providing a balanced view to help you assess whether this tool is the right fit for your woodworking needs.

Understanding CNC Technology

CNC (Computer Numerical Control) technology has transformed modern manufacturing by automating the control of machinery through computer programming. This technology enables precise, efficient, and repeatable production processes, driving innovation across multiple industries, from woodworking and musical instruments to advertising and model-making. The heart of CNC technology lies in its ability to interpret digital instructions and convert them into physical actions, controlling tools like lathes, mills, routers, and laser machines to perform intricate tasks such as cutting, drilling, milling, and engraving.

From a technical perspective, CNC machines operate on multiple axes, typically ranging from three to five, allowing for complex movements and enabling the production of highly detailed workpieces. The machines are programmed using specialized software, with G-code being the most commonly used language. This code translates design files into machine commands, dictating every movement, speed, and cut. This process eliminates the variability caused by human error, allowing for high repeatability in production. Whether working with hardwood, softwood, plywood, or composite materials, CNC routers offer unparalleled precision, making them ideal for mass production as well as custom woodworking projects.

CNC technology also offers significant economic and productivity advantages. By reducing manual labor and minimizing human error, CNC machines increase production speed and consistency. They enable mass production with identical outputs, streamlining workflows and reducing material waste. Furthermore, their ability to run continuously, even with minimal supervision, enhances efficiency in high-demand environments. Additionally, the scalability of CNC technology—from desktop models for hobbyists to industrial CNC routers—makes it accessible to businesses of various sizes.

CNC technology also enhances design versatility. With the ability to process digital files, woodworking CNC routers can create virtually any shape or pattern imaginable. This opens up creative possibilities for custom furniture, decorative woodwork, and architectural features that would be difficult, if not impossible, to achieve using traditional techniques. Furthermore, the integration of 3D modeling software allows designers to visualize and refine their creations before production, ensuring that the final product meets aesthetic and functional requirements.

Moreover, CNC technology’s impact extends beyond manufacturing. It has revolutionized industries like architecture and art, meeting the precise material handling needs of these industries. From producing detailed architectural models to crafting custom-designed sculptures, CNC machines enable creators to achieve previously unattainable levels of detail and complexity.

CNC technology, particularly in the form of woodworking CNC routers, has revolutionized the woodworking industry by offering unmatched precision, efficiency, and design flexibility. Driven by advances in software, automation, and materials science, CNC machines continue to evolve, enabling them to continue to drive innovation and productivity across the field well into the future.

Advantages of woodworking CNC router

Woodworking CNC routers offer several advantages that have revolutionized the way woodworking is approached, making them indispensable tools for modern businesses. Here are some key advantages:

Precision and Accuracy

One of the most notable advantages of a woodworking CNC router is its exceptional precision and accuracy. CNC routers are controlled by digital files and computer software, ensuring that every movement and cut is calculated with a high degree of accuracy. This precision allows users to produce intricate and detailed designs consistently, minimizing human error and achieving tight tolerances. Whether cutting, carving, or engraving, CNC routers deliver reliable results with exact measurements, which offers advantages in industries that demand consistency and detail.

Increased Efficiency and Time Savings

Woodworking CNC routers greatly increase efficiency by automating what would otherwise be time-consuming manual processes. Once a design is programmed into the machine, it can operate continuously, performing complex operations like cutting, drilling, or shaping in a fraction of the time it would take using traditional methods. Additionally, the ATC CNC router’s ability to complete multiple tasks without manual tool changes reduces downtime, allowing for faster production cycles. This time savings is especially beneficial in large-scale manufacturing, where speed determines whether deadlines can be met and large orders can be fulfilled.

Versatility and Flexibility

CNC routers are highly versatile and can handle a wide variety of tasks, from simple cuts to complex three-dimensional carvings. They can work with different types of wood and other materials such as plastics and composites, allowing for a wide range of applications. This versatility makes CNC routers ideal for everything from furniture production and cabinetry to intricate decorative items. Moreover, CNC routers can easily switch between different operations, such as cutting, drilling, and engraving, without needing separate machines, giving users flexibility in managing diverse woodworking projects.

Reproducibility and Consistency

A key advantage of CNC routers is their ability to produce identical workpieces and designs with consistent quality, even across large production runs. Once a design is programmed, the machine can replicate it as many times as needed, ensuring uniformity in each piece. This reproducibility guarantees that each product meets the same specifications, reducing defects and ensuring customer satisfaction. Even for custom designs, the CNC router can easily produce multiple exact replicas.

Handling Complex Geometries and Intricate Details

Woodworking CNC routers excel in producing complex geometries and intricate details that would be challenging or impossible to achieve using traditional woodworking tools. Whether creating detailed carvings, intricate patterns, or complex joinery, CNC routers can execute these designs with ease and precision. Their ability to move in multiple axes allows for greater design freedom, enabling the production of curved surfaces, 3D shapes, and detailed textures. This makes CNC routers a powerful tool for custom work, high-end furniture, and architectural elements.

Automation and Remote Operation

CNC routers automate the woodworking process, reducing the need for manual intervention and allowing for continuous production. Once the design is loaded, the CNC router can work independently, performing complex operations without constant supervision. Many CNC routers also offer remote operation capabilities, allowing users to monitor and control the machine from a distance, further enhancing productivity. This level of automation reduces the need for skilled labor, cutting down on labor costs. One operator can manage several machines simultaneously, further optimizing labor resources.

Reduced Material Waste

The precision with which CNC routers operate ensures that every cut follows exact programmed paths, optimizing the use of wood materials. CNC routers utilize nesting software that strategically arranges multiple designs within a material sheet to maximize material usage and reduce off-cuts. This not only lowers material costs but also makes the manufacturing process more sustainable by minimizing scrap. For businesses dealing with expensive wood types, the ability to reduce waste can have a significant impact on profitability and environmental responsibility.

Improved Safety

CNC routers enhance workplace safety by automating operations that would otherwise require manual tool handling. Operators interact with the machine through a control interface, limiting direct contact with cutting tools, saws, and other potentially hazardous equipment. This greatly reduces the risk of accidents and injuries associated with traditional woodworking methods. Additionally, CNC routers often come equipped with built-in safety features, such as emergency stop buttons and safety enclosures, further minimizing the chance of accidents.

Woodworking CNC routers provide exceptional precision, speed, and versatility, making them a valuable tool for both hobbyists and large-scale manufacturers. Their ability to produce complex designs, optimize material usage, and maintain consistent quality has transformed modern woodworking, offering significant advantages in terms of productivity, customization, and cost efficiency.

Disadvantages of woodworking CNC router

While woodworking CNC routers offer numerous advantages, they also come with certain drawbacks that should be considered before investing in this technology. Below are the key disadvantages of woodworking CNC routers:

Initial Investment Cost

The upfront cost of a woodworking CNC router is often substantial. Depending on the size, power, and functionality, prices can range from a few thousand to tens of thousands of dollars. Beyond the cost of the machine itself, businesses must also account for expenses related to software, installation, accessories, and initial setup. This can be a significant financial hurdle, especially for small workshops or individual craftsmen. While the investment may pay off in the long run through increased efficiency, the initial expenditure remains a critical consideration.

Learning Curve and Training Requirements

Operating a CNC router requires knowledge of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, as well as machine programming skills. For those unfamiliar with these technologies, there is a steep learning curve. Businesses may need to invest in training for operators to ensure they can use the machine efficiently and safely. Even experienced woodworkers may find it challenging to transition to digital methods, and programming errors can result in wasted material or damage to the machine, adding to operational costs.

Maintenance and Upkeep

CNC routers require regular maintenance to ensure smooth operation, which includes cleaning, tool changes, lubrication, and periodic calibration. The router bits and spindles wear out over time and must be replaced, adding to operating expenses. Any mechanical or electronic malfunctions may result in downtime, requiring specialized repair services that could further disrupt production schedules. For smaller businesses, maintaining a CNC router can be both costly and time-consuming.

Reliance on Electricity and Technology

CNC routers are heavily dependent on electricity and computer systems to function. Power outages or fluctuations can interrupt operations, causing delays or potential damage to the equipment. Additionally, the reliance on software means users are subject to issues such as software bugs, compatibility problems, or licensing fees for updates. When technical problems arise—whether in the software or the machine itself—they can halt production until the issue is resolved, creating a dependency on technology for smooth operations.

Limited Creativity and Artistic Expression

While CNC routers excel in precision and efficiency, they can also limit creative expression. Traditional woodworking often involves personal craftsmanship, with each piece reflecting the artisan’s unique style and techniques. In contrast, CNC routers reproduce designs based on programmed instructions, which can result in uniform outputs. For projects where customers value handcrafted uniqueness, such as custom furniture or art pieces, the automated nature of CNC routers may not align with expectations for originality or artistic expression.

Size and Space Limitations

CNC routers, particularly larger industrial models, require substantial space in a workshop. In addition to the machine, there must be adequate room for material storage, finished products, and a computer workstation for programming. Dust extraction systems or ventilation may also be necessary to maintain a safe work environment, further increasing space requirements. Smaller workshops may find it challenging to accommodate a CNC router without significant reorganization, which could limit its practicality for some users.

While woodworking CNC routers offer substantial benefits in terms of precision, efficiency, and versatility, their disadvantages should be carefully weighed. For businesses or individuals considering investing in a CNC router, evaluating these challenges alongside the potential benefits is beneficial to make an informed decision.

Application of CNC router in woodworking projects

Woodworking CNC routers have become essential tools in modern woodworking, offering precision and efficiency for a variety of applications. Here are key ways CNC routers are applied in woodworking projects:

Furniture Manufacturing

CNC routers streamline the production of furniture by automating complex cutting and shaping processes. They can create parts for cabinets, tables, chairs, and beds with consistent precision. CNC routers are also used for producing stair components, such as handrails and balusters, with complex curves and profiles. This automation allows manufacturers to reduce production time while maintaining uniform quality across multiple units.

Cabinetry and Joinery

In cabinetry, CNC routers excel at cutting panels, drawers, and cabinet doors with precise measurements. They can also create joinery features, such as dovetail or mortise-and-tenon joints, ensuring a perfect fit. Additionally, CNC routers can engrave or carve decorative patterns directly into cabinet doors, offering enhanced customization for high-end kitchen or office cabinetry.

Sign Making and Decorative Panels

CNC routers are widely used in creating wooden signs, both for commercial and artistic purposes. They can carve text, logos, and intricate designs with precision, making them ideal for custom signage. Similarly, decorative wall panels or partitions with detailed patterns are easily produced using CNC routers, enhancing architectural and interior design projects with bespoke features.

Custom Wood Art and Sculptures

Artists and craftsmen use CNC routers to produce intricate wood carvings and sculptures. These machines enable them to replicate or scale complex designs, offering creative flexibility. CNC routers allow artists to experiment with 3D designs and detailed textures that would be difficult to achieve by hand, expanding the possibilities for artistic expression in woodwork.

Prototyping and Model Making

CNC routers are valuable tools for creating prototypes and models. In woodworking, designers can use these machines to produce accurate mock-ups of furniture, architectural elements, or product designs. This allows them to evaluate proportions, aesthetics, and functionality before committing to full-scale production. The ability to quickly iterate designs speeds up the product development process.

Wooden Toys and Instruments

CNC routers are ideal for producing complex shapes required for wooden toys, such as puzzles, dollhouses, and model kits. These machines also play a role in the production of musical instruments like guitars, violins, and ukuleles. CNC routers can carve bodies, necks, and intricate sound holes with consistency, ensuring high-quality results in both toys and instruments.

CNC routers have a broad range of applications in woodworking, from furniture and cabinetry to art, signs, and prototypes. Their precision, speed, and versatility make them indispensable tools for both large manufacturers and small workshops, enabling efficient production and endless creative possibilities.

Summarize

Woodworking CNC routers can produce complex designs with consistency and minimal waste, making them ideal for both mass manufacturing and custom projects. However, they also come with numerous challenges. Therefore, whether a CNC router is the right investment depends on the specific needs and goals of the user. By weighing both the benefits and limitations, woodworkers can make informed decisions about how best to incorporate CNC technology into their operations, striking the right balance between efficiency, creativity, and functionality. Continue reading “Types of Wood Suitable for CNC Router Processing” to expand your knowledge.

If you’re looking to invest in a high-quality woodworking CNC router, AccTek CNC is a good choice. As a professional CNC router manufacturer based in China, AccTek CNC offers a comprehensive range of machines designed to meet the needs of modern woodworking businesses. While CNC routers require an initial investment and technical training, AccTek provides excellent customer support, helping users overcome these challenges with ease. With a focus on innovation and reliability, AccTek CNC is a trusted partner for woodworkers seeking to enhance productivity and unlock new creative possibilities.