Top Ranked 2040 ATC CNC Router

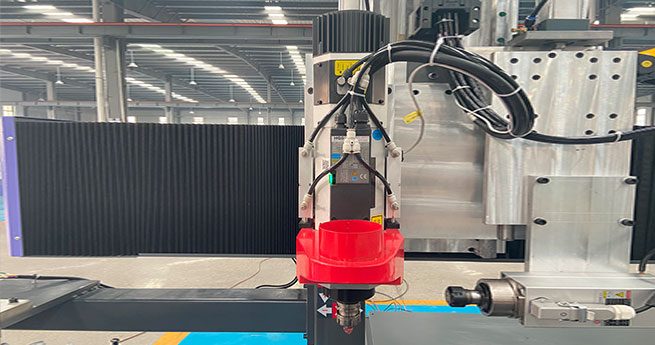

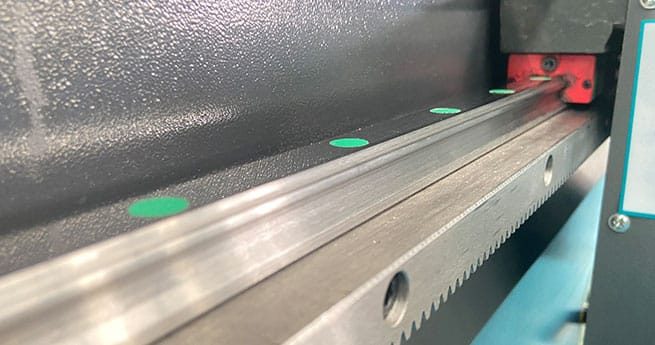

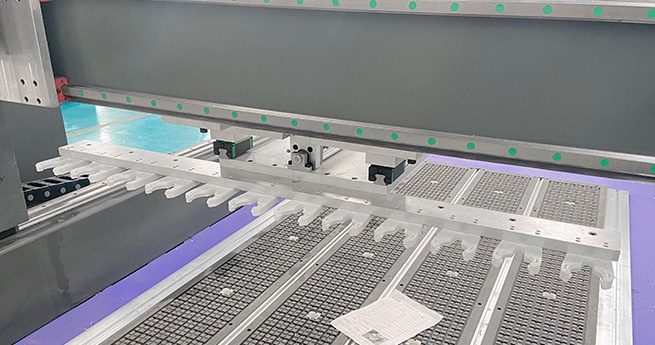

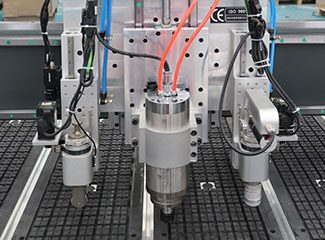

The AKM2040C CNC router is a robust ATC machine designed for high-precision wood and form engraving, featuring a durable cast iron body, advanced automation, and reliable motion control for efficient production.

4 reviews for AKM2040C CNC Router

Candy –

Thrilled with my AccTek CNC router, it runs smoothly, and the purchase exceeded our expectations. The machine’s excellent quality prompts us to wholeheartedly recommend it to friends. A valuable investment and a testament to AccTek CNC’s commitment to top-notch products and customer satisfaction.

Johnny –

Highly satisfied with my CNC router, it works great. Considering the purchase of one with an automatic tool changer for the next upgrade. AccTek CNC’s performance has been exceptional, prompting continued loyalty and future investment.

Mason –

Extremely pleased with my AccTek CNC router, tirelessly working every day without a hitch. The machine’s robust and well-made design reflects excellent quality. Delighted with the purchase, it’s proven to be a reliable and sturdy asset to my work.

Savannah –

Grateful for my AccTek CNC router in excellent condition. Thank you so much. As I prepare my studio for connecting and using the machine, I look forward to sharing more photos and my detailed review in the coming days. AccTek CNC has already been impressed with its quality and service.