- 12-17 Min Read

Operating a CNC router may seem complex at first, but a DSP controller simplifies the process by allowing users to run jobs directly from a handheld device, without needing a constant computer connection. DSP controllers are especially popular in woodworking, signage, and small-scale manufacturing due to their ease of use, reliability, and standalone functionality.

To make the most of a CNC router with a DSP controller, operators need to understand how to correctly set up and manage each step of the workflow. From file preparation and zero-point setting to navigating the DSP menu and running cutting programs, each phase affects the accuracy and safety of the machine. In this article, we’ll guide you through the complete operation process, provide tips for smooth use, and share practical troubleshooting advice, helping you take full advantage of your CNC router’s capabilities.

Understanding the DSP Controller

What is a DSP Controller?

A DSP (Digital Signal Processor) controller is a standalone control system commonly used in CNC routers to manage and execute cutting operations. Unlike PC-based control systems that require a constant connection to a computer, a DSP controller operates independently. Users simply load G-code files onto a USB drive, insert it into the DSP unit, and control the entire CNC routing process directly through the handheld device. This eliminates the risk of computer crashes or software freezes interrupting the cutting process and offers greater flexibility for workshop environments where space or reliability of a PC may be a concern.

Key Components of a DSP Controller

The DSP controller is built around a specialized chip that processes digital signals in real-time, allowing it to interpret machining instructions efficiently and send precise commands to the motors and spindle. Here is its composition:

- Handheld Unit: The handheld device is the central user interface. It’s compact, lightweight, and designed for one-handed operation. This unit contains the screen, control buttons, and processing hardware, allowing operators to control the CNC router without a connected PC.

- LCD Display Screen: The LCD screen displays menus, file names, coordinates, and machine status in real-time. It helps users navigate through setup, job selection, axis movement, and execution steps. Some models also offer simple toolpath previews.

- Keypad and Function Buttons: The keypad includes directional buttons (X, Y, Z axis movement), numeric inputs, and function keys like Start, Pause, Stop, Home, Reset, and Menu Navigation. These buttons provide direct access to machine functions, allowing for quick adjustments during operation.

- USB Port: The USB interface allows users to load G-code or machining files from a flash drive. This feature enables completely offline operation, enhancing flexibility and minimizing computer dependency in the workshop.

- Emergency Stop Button (if external): In some setups, the DSP controller is connected to an external emergency stop button for safety. Pressing this immediately halts all machine movements to prevent damage or injury.

- Internal Memory (Optional): Some advanced DSP models have limited internal memory to store recent files or run small programs directly, further improving workflow efficiency.

These components work together to offer a reliable, user-friendly experience. Because of its portability, simplicity, and robust performance, DSP controllers are widely used in woodworking, sign making, and other applications where ease of use and operational stability are priorities.

Pre-Operation Preparation

Before starting any cutting task with a CNC router equipped with a DSP controller, it’s crucial to go through a structured setup process. This stage includes designing your job, generating compatible files, and setting up the machine environment for safe operation. Proper pre-operation preparation not only ensures cutting accuracy but also helps prevent errors and machine damage.

File Preparation

Proper file preparation is the first step in operating a CNC router with a DSP controller. This process involves converting your design idea into a machine-readable format that the controller can execute accurately.

- Designing with CAD Software: Begin by creating your design using CAD (Computer-Aided Design) software such as AutoCAD, CorelDRAW, SolidWorks, or Illustrator. This stage allows you to define shapes, text, dimensions, and other visual elements of your project.

- Generating Toolpaths with CAM Software: After finalizing the design, import it into CAM (Computer-Aided Manufacturing) software like ArtCAM, Aspire, or VCarve. CAM software converts your visual design into toolpaths, it detailed instructions that tell the CNC router how to move, where to cut, and what depth to use.

- Exporting to a Compatible G-code Format: Once the toolpaths are created, the final step is to export the job in a format compatible with your DSP controller. Common formats include *.nc, *.mmg, or *.txt, depending on the specific DSP model.

Transferring Files to DSP

After generating the appropriate G-code file, the next step is to transfer it to your CNC router’s DSP controller.

- Save the G-code to the USB Drive: Once your G-code is exported from the CAM software, save it to a USB flash drive. Make sure the file name is simple and recognizable to avoid confusion.

- Insert the USB into the DSP Controller: Plug the USB drive into the dedicated port on the DSP controller. Most controllers recognize the device automatically. Ensure the drive is securely connected, and wait a few moments for the system to read the stored files.

- Load the Desired File from the Controller Interface: Using the DSP controller’s navigation buttons and display screen, locate the USB storage menu. Browse the list of files, select the appropriate G-code, and load it into the system.

Machine Initialization

Before starting any cutting operation, it’s essential to properly initialize your CNC router to ensure accurate movement and positioning.

- Turn on the Main Power and Controller: Begin by switching on the main power supply to the CNC router. Once the machine powers up, turn on the DSP controller by pressing its power button. As the system starts, make sure there are no error messages or abnormal sounds. Confirm that the control interface is responsive and that the emergency stop button is released and functioning properly.

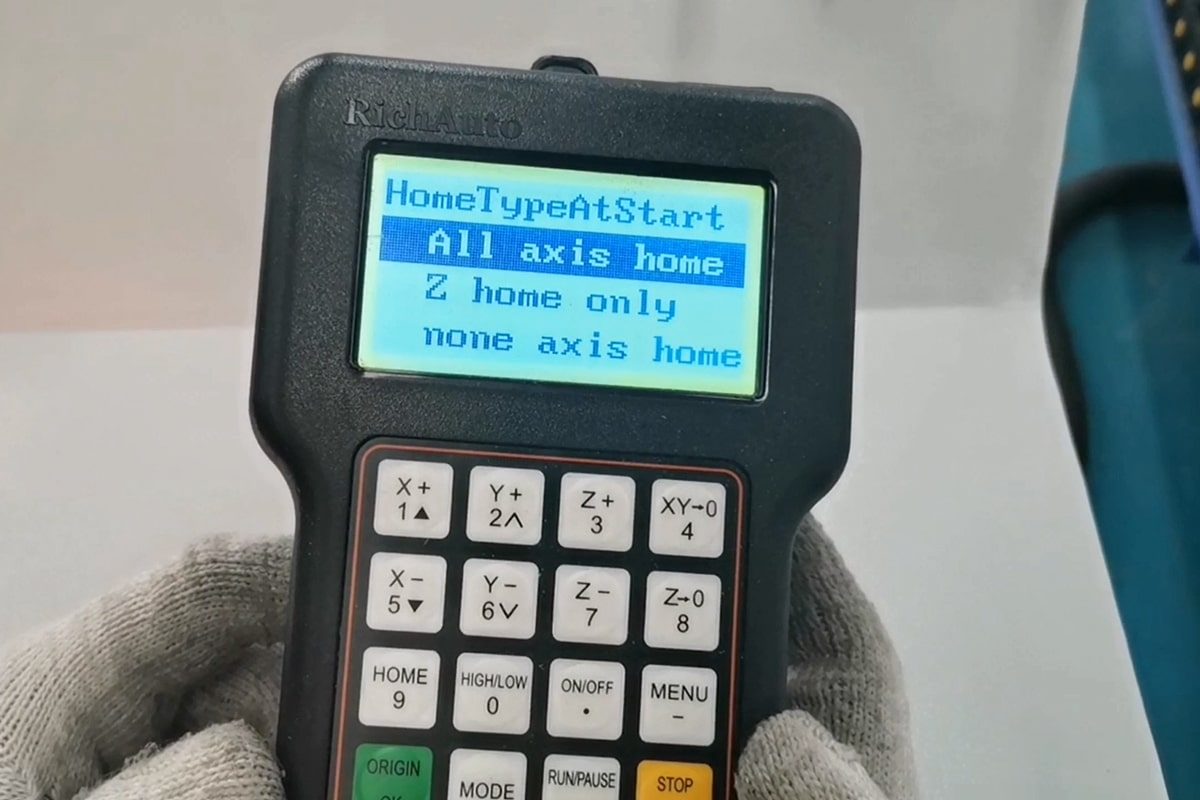

- Homing the Machine to Establish a Reference Point: Once powered on, the machine must be homed to define its reference point. Homing moves each axis (X, Y, and Z) to its origin until it contacts the limit switches, which signals the controller of the machine’s exact zero position. Use the DSP controller’s menu to initiate the homing function.

Material and Tool Setup

Proper material and tool setup ensures safety, precision, and optimal cutting performance with a CNC router.

- Securing the Workpiece to the Table: Begin by placing the material flat on the workbench. Use clamps, a vacuum table, or double-sided tape to hold it firmly in place. Ensure there’s enough clearance around the edges to accommodate the toolpath and prevent collisions.

- Installing and Tightening the Correct Tool: Select the appropriate cutting bit based on your material and the toolpath defined in the CAM software. Insert the bit into the spindle collet and tighten it securely using the provided wrenches. Always double-check that the bit is properly seated and locked in place.

- Setting the Origin: Use the DSP controller to manually jog the spindle to the starting point of the job, usually the bottom-left corner of the workpiece. Lower the tool slowly until it just touches the material surface to set the Z-axis origin. Then, set the X, Y, and Z zeros using the controller’s interface.

Taking the time to carefully prepare before you begin operating your CNC router can help prevent errors, protect equipment, and increase workflow efficiency. With your setup complete and everything in place, you’re now ready to move on to operating the CNC router and running your job with confidence.

Operating the CNC Router

With all preparations complete, you can now begin operating the CNC router using the DSP controller. This stage involves navigating the controller’s interface, starting the job, and making adjustments as needed during the cutting process. Understanding how to manage these functions ensures efficient, precise, and safe operation.

Navigating the DSP Menu

Navigating the DSP controller’s menu is a fundamental part of operating a CNC router. The interface is designed for quick access to essential functions, allowing users to control the machine efficiently without a computer.

- File Selection: After inserting the USB drive, use the navigation keys on the DSP controller to access the file directory. Scroll through the list of stored G-code files and select the one you wish to run. Once selected, the file is loaded into the controller’s memory, ready to be executed.

- Preview Function: Some DSP controllers offer a basic preview function that displays a simplified image or outline of the toolpath. This allows you to confirm that the selected file matches the intended design.

- Manual Movement Keys (Jogging): The DSP controller also includes manual movement keys that let you jog the CNC router along the X, Y, and Z axes. You can move the spindle in small or large increments, depending on your needs, using directional buttons typically labeled with arrow symbols or axis names.

Running a Job

Once the machine is set up and the correct file is loaded, you’re ready to run the job. Operating the CNC router through the DSP controller involves three key actions:

- Starting the Program: After selecting the desired G-code file through the DSP controller, press the “Start” button to initiate the cutting process. The machine will begin executing the programmed toolpath immediately, following the sequence and parameters defined in the CAM software.

- Monitoring Progress Through the Display and Machine Feedback: As the job runs, keep an eye on the display for real-time status updates, and stay alert for any unusual sounds or movements. This helps detect issues like tool collisions, incorrect depths, or workpiece shifting early in the process.

- Pause, Stop, and Resume Functions: Pressing Pause temporarily halts the job while maintaining the current position, allowing for quick checks or minor adjustments. The Resume button continues the process from the paused point. If a critical error or safety concern arises, use the Stop button to immediately halt all machine movement.

Adjustment During Operation

While a CNC router is running, the DSP controller gives operators the ability to make real-time adjustments to improve safety, compensate for unexpected conditions, or recover from interruptions.

- Feed Rate Override: The DSP controller allows you to adjust the feed rate while the machine is running. If you notice excessive vibration, burning, or chipping, you can reduce the feed rate to slow down the cutting speed. Conversely, if the machine is cutting smoothly, you may increase the feed rate to improve efficiency.

- Emergency Stop Function: In case of a critical error, the emergency stop button immediately halts all machine movement and spindle activity. Pressing it cuts power to the motors, stopping the machine within seconds. After using the emergency stop, the controller will need to be reset before operation can continue.

- Restarting from the Breakpoint if Interruption: If a job is paused or stopped, the DSP controller often includes a breakpoint recovery function. This allows you to restart the job from the last executed line of G-code rather than beginning from the start.

By mastering the basic operating functions of the DSP controller, you can run your CNC router smoothly and respond quickly to any issues that arise during the machining process.

Post-Operation Steps

After completing a cutting job, it’s important to follow proper shutdown and cleanup procedures to maintain the machine’s longevity, ensure safety, and prepare for the next project. The post-operation process includes powering down the system, removing the workpiece, and cleaning both the machine and the work area.

Powering Off the Machine and DSP Controller

Once the cutting process is complete, use the DSP controller to return the spindle to a safe resting position. Then, power off the controller using its designated button or switch. Finally, turn off the main power to the CNC router. Always ensure the machine has come to a complete stop before shutting off power to avoid potential damage.

Removing the Finished Workpiece

Carefully remove the clamps, vacuum hold-downs, or other fixtures securing the material to the worktable. Gently lift the finished workpiece, checking for any remaining tabs or support structures that need trimming. Inspect the part for quality and verify that it matches the expected dimensions and design.

Cleaning the Work Area and Tools

Use a vacuum or dust collection system to remove debris from the worktable, tool holder, and surrounding area. Wipe down the machine surfaces, and clear the spindle and collet of any residue or material buildup. If needed, remove and store the cutting bit in a clean, dry place to preserve its sharpness.

Backing Up or Deleting Completed Files

Remove the USB drive from the DSP controller and transfer any completed files you want to keep to a computer or external storage. It’s also good practice to delete any outdated or unnecessary files from both the USB and the DSP memory. This keeps the controller organized and reduces confusion during future file selection.

By following these post-operation steps, you help extend the life of your CNC router, ensure a safe workspace, and maintain consistent production quality for every job. Consistent shutdown and cleanup habits are just as important as precise cutting when it comes to achieving long-term performance and productivity.

Maintenance Tips for Smooth Operation

Regular maintenance is beneficial for keeping your CNC router and DSP controller in top working condition. Proper upkeep reduces downtime, extends machine life, and ensures consistent cutting accuracy. Here are key maintenance tips to follow for smooth, reliable operation:

- Clean the Machine Regularly: After each job, remove dust, chips, and residue from the worktable, gantry, and moving parts using a vacuum or air blower. Accumulated debris can interfere with smooth motion and increase wear on mechanical components.

- Inspect and Lubricate Moving Parts: Check linear guides, ball screws, and bearings for signs of wear or lack of lubrication. Apply appropriate lubricants according to the manufacturer’s recommendations to keep the motion system running smoothly and prevent rust or corrosion. This ensures smooth motion, reduces vibration, and helps maintain precise axis alignment.

- Keep the DSP Controller Dry and Dust-Free: Wipe down the DSP controller with a clean, dry cloth after use. Avoid exposing it to moisture or excessive dust, as this can damage internal circuits or affect button responsiveness. When not in use, store the controller in a protective enclosure or cover to minimize environmental exposure.

- Check Tool Tightness and Bit Condition: Before each use, ensure the cutting tool is properly secured in the spindle collet. Inspect the bit for wear or damage and replace it as needed to maintain clean, precise cuts.

- Monitor Electrical Connections: Periodically inspect power cables, connectors, and grounding wires for any signs of damage, looseness, or wear. Poor electrical connections can lead to performance issues or safety hazards. Additionally, install a surge protector or uninterruptible power supply (UPS) to shield sensitive electronics from sudden voltage spikes, especially in areas with unstable power sources.

- Update Software and Firmware if Needed: If your DSP controller supports firmware updates, check periodically for new versions provided by the manufacturer. Keeping software up to date can improve functionality and fix known bugs. Follow the update instructions carefully to avoid data corruption or malfunction during the process.

- Maintain a Clean and Organized Work Area: A tidy environment reduces the risk of accidents, improves airflow around the machine, and ensures better visibility and access during operation and maintenance.

By implementing these maintenance routines, you’ll ensure your CNC router with DSP controller continues to perform reliably and accurately, job after job. Regular care not only protects your investment but also leads to higher-quality output and greater operational efficiency.

Common Mistakes and Troubleshooting

Even experienced CNC router operators can encounter issues when working with a DSP controller. Many problems arise from small oversights during setup or operation, but the good news is that most can be quickly resolved once identified. This section outlines common mistakes and troubleshooting tips to help you diagnose and fix problems efficiently.

G-Code Compatibility Issues

- Issue: The DSP controller fails to recognize or properly execute the selected file.

- Cause: The G-code file was not exported in a format compatible with the specific DSP controller model.

- Solution: Double-check your CAM software’s post-processor settings before exporting the toolpath. Select the format that matches your DSP controller’s requirements. It’s also advisable to use short, clear filenames and avoid special characters to improve compatibility.

- Prevention: Create a preset in your CAM software with the correct settings for your DSP controller and verify exported files on the DSP screen before starting a job.

Machine Not Homing Properly

- Issue: The CNC router fails to home properly or does not move accurately to its designated positions.

- Cause: Limit switches may be dirty, misaligned, or malfunctioning. Alternatively, mechanical obstructions or incorrect machine parameters could interfere with positioning.

- Solution: Clean and inspect all limit switches and ensure they click or trigger as the machine moves. Also, verify that no debris or material is blocking the axes and that all motion components are securely fastened. Verify that all cables are connected and the DSP settings are correctly configured.

- Prevention: Perform regular maintenance checks on limit switches and wiring. Keep the guide rails and machine bed clean and calibrated.

Z-Axis Zeroing Error

- Issue: The tool cuts too deep or hovers above the material.

- Cause: Improper Z-axis origin setting, or the tool is not properly secured in the spindle collet.

- Solution: Use the DSP controller’s jog function to manually lower the tool until it lightly touches the material surface. Then reset the Z-axis zero point through the controller interface. Always confirm that the cutting bit is fully inserted and tightly fastened.

- Prevention: Incorporate a standard zeroing procedure into your setup routine. Consider using a touch-off plate or Z-probe for more precise and repeatable results.

Controller Freezing or Lagging

- Issue: The DSP controller freezes or stops responding during operation, interrupting the job.

- Cause: Causes may include corrupted G-code files, overloaded DSP memory, poor-quality USB drives, electrical interference, or exposure to dust and moisture.

- Solution: Restart the controller and remove the USB drive. Check the file for errors using your CAM software or try re-exporting it. Use a high-quality, properly formatted USB drive, and keep your controller clean and dry.

- Prevention: Regularly clean the controller, avoid overloading its memory, and back up or delete unused files. Only use reliable USB storage devices and avoid operating in high-humidity or dusty environments without protective covers.

Poor Cutting Quality

- Issue: The final product has rough edges, burns, chatter marks, or dimensional inaccuracies.

- Cause: Common causes include dull or incorrect tools, inappropriate feed and speed settings, loose mechanical components, or inaccurate zeroing.

- Solution: Stop the job and inspect the cutting bit for wear or damage. Recheck feed rate and spindle speed settings in the CAM file. Make sure all mechanical parts are tight and properly aligned. Re-zero the machine if necessary.

- Prevention: Routinely inspect and replace cutting tools as needed. Calibrate your machine periodically and maintain consistent maintenance of bearings, belts, and rails. Use test cuts to fine-tune cutting parameters before full-scale jobs.

Mistakes and technical hiccups are common in CNC operations, but most issues with a DSP-controlled router can be traced to setup errors, file formatting problems, or basic maintenance lapses. By staying alert to these common problems and knowing how to troubleshoot them, you can minimize downtime, avoid costly rework, and keep your projects running smoothly.

Summarize

Operating a CNC router with a DSP controller may seem complex at first, but with a solid understanding of the process, it becomes a manageable and highly efficient workflow. The DSP controller’s standalone design offers flexibility, reliability, and ease of use, making it a great choice for both beginners and experienced users. By following the steps outlined in this guide and staying proactive with maintenance and troubleshooting, you’ll be well-equipped to achieve precise, consistent results on every project.

AccTek CNC is a trusted CNC router manufacturer based in China, offering high-quality machines and tailored solutions for various industries. Whether you’re a beginner or a seasoned operator, you can rely on us for expert support, reliable equipment, and comprehensive CNC solutions to meet your production needs. Contact us today to get professional CNC solutions that match your workflow, budget, and goals.