- 10-15 Min Read

As CNC router users look to expand their capabilities beyond flat surface machining, adding a rotary axis becomes a compelling upgrade. A rotary axis allows the machine to rotate the workpiece during cutting, enabling the production of cylindrical and complex 3D shapes with greater efficiency. However, different types of rotary axes have different performance and functionality. From compact table-mounted attachments to fixed front-facing units and independent side-mounted configurations, each type of rotary setup offers distinct advantages and trade-offs.

Choosing the right one depends on several factors, including your material size, machining frequency, budget, and available space. A small removable rotary axis may be ideal for occasional projects, while a fixed or independent rotary system is better suited for heavy-duty or high-volume work. In this article, we’ll explore the main types of rotary axis setups, compare their pros and cons, and provide practical guidance to help you choose the best option for your CNC router workflow.

Understanding the Rotary Axis CNC Router

Incorporating a rotary axis into your CNC router setup dramatically expands your machining capabilities. Before choosing the right rotary axis, it’s important to understand what a rotary axis CNC router is and how it enhances your machine’s functionality.

What Is a Rotary Axis on a CNC Router?

A rotary axis, often referred to as the 4th axis, is an optional component that adds rotational movement to a standard 3-axis CNC router. While a typical CNC router moves along the X (left–right), Y (front–back), and Z (up–down) axes, the rotary axis introduces a rotating A-axis, which allows the workpiece to turn during machining. This rotation enables the machine to perform complex cuts on cylindrical or rounded materials, making it possible to carve, engrave, or cut along curved surfaces with high precision.

The rotary axis is typically equipped with a motorized chuck or fixture that holds the workpiece and rotates it in sync with the cutting tool. This allows for continuous or indexed rotation during the cutting process. By enabling multi-sided machining in a single setup, a rotary axis improves efficiency, reduces repositioning, and expands the range of possible designs and part geometries.

Common Applications of a Rotary Axis on a CNC Router

The rotary axis transforms a standard CNC router into a powerful tool for machining round or cylindrical workpieces. Its ability to rotate the material during cutting unlocks a range of specialized applications. Here are some of the most common applications:

- Column Engraving: Rotary axes are ideal for engraving decorative patterns, text, or relief designs onto cylindrical columns and pillars. By rotating the column during machining, the CNC router can achieve consistent, continuous detailing around the entire surface, something that would be difficult.

- Cylindrical Carving: From table legs and chair spindles to sculptural art pieces, cylindrical carving is a staple application for rotary axis CNC routers. The rotating axis allows for smooth and symmetrical shaping of round workpieces, enabling complex 3D contours and seamless transitions.

- Pipe Cutting: The axis rotates the pipe while the cutting head performs operations like slotting, drilling, notching, or profile cutting. This ensures precise alignment and efficient machining without the need to reposition the workpiece manually.

These applications demonstrate how a rotary axis greatly expands the functionality of a CNC router, allowing it to handle complex projects with ease and precision. With this foundation in place, you’re better prepared to evaluate which type of rotary setup will best suit your specific production needs.

Table-Mounted Rotary Attachments

Table-mounted rotary attachments are one of the most common and flexible rotary axis configurations for CNC routers. They typically consist of a motorized rotary chuck or roller system that holds and rotates the workpiece during machining. These attachments are portable units that can be placed directly on the machine bed when needed.

Advantages

Table-mounted rotary attachments offer several practical advantages, especially for users looking to add 4th-axis capabilities without committing to a permanent or complex setup. Here are the key benefits:

- Flexibility and Removability: These attachments can be easily installed when needed and removed when not in use. This allows you to switch between flat work and rotary work without modifying the machine.

- Cost-Effective Solution: Compared to fixed or industrial-grade rotary systems, table-mounted attachments are more affordable. They provide an economical entry point for hobbyists, small businesses, and educational institutions to experiment with rotary machining.

- Easy Setup and Integration: Most table-mounted rotary units are designed for plug-and-play installation. They typically integrate with the CNC controller with minimal wiring or calibration, making them accessible even to beginner users.

- Space-Saving Design: Since they don’t require dedicated mounting or structural changes to the machine, they’re perfect for workshops with limited space. You can store the attachment away when not in use.

- Ideal for Small and Medium Workpieces: They’re well-suited for engraving or carving items like cylindrical pens, cups, vases, or small decorative columns. This makes them especially popular for personalized products and custom work.

Limitations

While table-mounted rotary attachments offer flexibility and affordability, they also come with certain limitations that may impact their suitability for some users or applications.

- Limited Workpiece Size and Weight: Because the attachment sits on the machine bed, the size and weight of the workpiece are restricted by the available table space and gantry clearance. Heavier or longer materials may cause instability or exceed the machine’s capacity, resulting in reduced machining accuracy or potential equipment damage.

- Reduced Flatbed Working Area: When the rotary attachment is in use, it occupies a portion of the flat working surface. This reduces the effective cutting area for other tasks and may require time-consuming removal and reinstallation if you frequently switch between rotary and flat jobs.

- Stability and Rigidity Constraints: Table-mounted units are not permanently fixed to the machine frame, which can lead to slight movement or vibration during high-speed cutting or with unevenly balanced workpieces. This can affect the overall surface finish or dimensional accuracy.

- Not Ideal for High-Volume Production: These attachments are best suited for low to moderate usage. For businesses with frequent rotary machining needs or high-output production, a more robust, fixed, or side-mounted rotary system offers greater durability and efficiency.

- Manual Alignment and Setup: Since the attachment is portable, users often need to manually align and calibrate it before each use. This adds to the setup time and may lead to inconsistent results without proper fixture alignment or experience.

4-Axis CNC router with table-mounted rotary attachments strike a balance between flexibility, cost, and ease of use. They are a great entry-level solution for light-duty rotary work, but they may not meet the demands of large-scale, heavy-duty, or precision-intensive applications.

Fixed Rotary Axis in Front of the 4-Axis CNC Router

Unlike table-mounted attachments, this type of rotary axis in front of the CNC router is securely installed to the machine base, typically aligned with the X-axis, and positioned just outside or in front of the machine bed. It’s a preferred choice in environments where rotary machining is a regular part of the workflow.

Advantages

A fixed rotary axis mounted in front of the CNC router offers several significant advantages, especially for users engaged in frequent rotary machining. Here are the key benefits:

- Improved Stability and Rigidity: Because the rotary axis is permanently fixed to the machine’s frame, it provides a solid and stable foundation for machining. This reduces vibration and movement during cutting, resulting in better precision, surface finish, and repeatability.

- Ideal for Long and Heavy Workpieces: This configuration is well-suited for processing large-diameter or extended-length materials, such as furniture legs, wooden columns, stair balusters, and other elongated cylindrical parts. It offers better support and alignment, minimizing deflection or wobbling during rotation.

- No Interference with Flatbed Operations: Since the rotary axis is positioned in front of the machine bed—outside the main cutting area—it does not occupy the workspace used for flat sheet cutting. This allows you to switch between rotary and flat work without having to install or remove any components, improving workflow efficiency.

- Enhanced Accuracy and Repeatability: With its fixed positioning and proper calibration, the front-mounted rotary axis ensures consistent alignment, leading to high machining accuracy across multiple parts.

- Professional and Production-Ready Setup: This type of rotary axis is built for frequent or daily use. It provides the reliability and durability that industrial users, furniture manufacturers, and custom woodshops need to meet production demands.

Limitations

While a fixed rotary axis mounted in front of the CNC router offers stability and production-ready performance, it also comes with certain limitations that should be considered before choosing this configuration:

- Increased Machine Footprint: Installing a rotary axis in front of the machine adds to the overall space requirement. This setup may extend the physical length of the machine and demand more workshop floor space.

- Less Flexibility: Unlike table-mounted rotary attachments, fixed rotary axes cannot be easily removed or repositioned. Once installed, the setup becomes semi-permanent, which may limit your flexibility if your machining needs change in the future.

- Not Easily Shared Between Machines: Because it is permanently installed and aligned to one machine, the rotary axis cannot be quickly transferred to another CNC router. This reduces versatility in multi-machine workshops unless each machine has its dedicated rotary axis.

A fixed rotary axis mounted in front of the CNC router is a durable, production-ready solution for users who require rotary functionality regularly. It offers a higher level of accuracy, ease of workflow integration, and stability compared to portable options, making it a preferred choice for users who consistently work on cylindrical parts.

Side-Mounted Rotary Axis CNC Router

The side-mounted rotary axis is an advanced configuration in which the rotary unit is placed beside the CNC router bed, usually supported by an independent frame or base structure. Unlike table-mounted or front-fixed types, this setup allows the rotary axis to function separately from the main cutting area, making it ideal for industrial-grade cylindrical materials.

Advantages

A side-mounted rotary axis offers powerful functionality and operational advantages for CNC users involved in heavy-duty or high-volume rotary machining. Here are its main advantages:

- Supports Large and Heavy Workpieces: The side-mounted rotary axis is typically installed on an independent frame, allowing it to handle longer, wider, and heavier cylindrical materials without putting stress on the main CNC table or gantry.

- Does Not Interfere with Flatbed Operations: Because the rotary axis is placed beside the machine, it operates independently from the flat cutting bed. This allows users to switch between rotary and flat machining without moving or removing equipment, streamlining workflow and reducing downtime.

- High Stability and Rigidity: Mounted on a dedicated support structure, the side-mounted rotary axis offers excellent vibration control and machining precision. This ensures consistent, high-quality results even when processing heavy or unbalanced workpieces at higher speeds.

- Enhanced Safety and Separation: By physically separating rotary machining from the main bed, it’s easier to manage material handling, chip removal, and operator safety, especially during continuous production.

Limitations

While a side-mounted rotary axis delivers superior performance and flexibility for large-scale or industrial applications, it also comes with certain limitations that should be carefully considered before investing. Here are the key drawbacks:

- High Initial Cost: Side-mounted rotary axes are typically custom-engineered, require a dedicated support frame, and may involve additional automation or control system integration. This makes them significantly more expensive than table-mounted or front-fixed options, which may not be suitable for users with limited budgets.

- Larger Space Requirements: This configuration demands considerable floor space beside the CNC machine to accommodate long rotary assemblies and support equipment. It may not be practical for small workshops or environments with restricted layouts.

- Limited Portability and Flexibility: Unlike removable rotary attachments, a side-mounted unit is permanently positioned and not easily reconfigured or shared between machines. This limits flexibility if your production needs change or if you want to reallocate equipment.

- May Require Additional Training: Operators unfamiliar with side-mounted systems may need extra training to manage setup, toolpaths, material handling, and safety precautions.

A side-mounted rotary axis CNC router is the most robust and production-oriented solution. Though this setup comes at a higher cost and requires more floor space, it offers maximum stability and the ability to run rotary and flat cutting tasks independently, minimizing downtime and improving throughput. It is best suited for businesses that perform frequent or large-scale cylindrical machining and have the resources to support this advanced configuration.

Factors to Consider When Choosing a Rotary Axis

Selecting the right rotary axis for your CNC router isn’t just about adding a 4th axis—it’s about ensuring that the configuration matches your specific materials, production goals, and workspace. To make the right choice, here are the key factors you should evaluate:

Application Type

Consider the nature of your work. Are you engraving decorative wooden columns, carving cylindrical art pieces, or cutting industrial metal pipes?

- Light-duty engraving or carving: For applications like custom cylindrical signs, vases, totems, or artistic sculptures, where the shapes are smaller, a table-mounted rotary attachment may be sufficient.

- Frequent woodworking or furniture production: A fixed front-mounted rotary axis is ideal. It provides the support and rigidity needed for consistent, high-quality results in woodworking.

- Industrial pipe or tube processing: A side-mounted rotary axis with independent support offers the heavy-duty capacity and precision alignment required for industrial-level cutting.

Material Size and Weight

Your rotary axis must match the physical characteristics of your materials. The rotary axis must not only support the dimensions of your workpieces but also ensure they remain stable during rotation and cutting.

- Small and light parts: A table-mounted rotary attachment is ideal. It’s easy to place and remove from the machine bed and provides sufficient support for small-scale jobs.

- Medium-Sized Workpieces: A fixed rotary axis in front of the machine offers better rigidity and alignment for medium to moderately heavy parts.

- Long or heavy workpieces: A side-mounted rotary axis with an independent base or support frame is designed for large, heavy, or industrial workpieces. It provides the highest load capacity and maintains cutting accuracy across the full length of the material.

Frequency of Use

Rotary machining can be an occasional task for some users or a daily necessity for others. Ask yourself how often you’ll use the rotary axis.

- Occasional or Project-Based Use: Infrequent users benefit from a solution that can be deployed quickly and stored when not needed. A table-mounted rotary attachment offers the best flexibility. It can be set up as needed and doesn’t interfere with normal flatbed operations when removed.

- Regular or Scheduled Use: Users who include rotary machining as part of a regular production cycle need a system that provides repeatable performance without frequent adjustments. A fixed rotary axis in front of the machine provides consistent alignment and easy access for regular jobs without setup hassle.

- Continuous or High-Volume Use: In industrial environments where the rotary axis is used daily or in long production runs. A side-mounted rotary axis offers the highest durability and productivity. It allows rotary operations to run independently and continuously.

Machine Size and Compatibility

Not all CNC routers are built to support every rotary axis configuration. The machine’s size, structure, and control system must all align with the rotary axis configuration to ensure smooth integration and safe operation.

- Gantry Clearance and Working Area: The rotary axis and the rotating workpiece must fit comfortably within the machine’s travel limits. Make sure there is enough gantry clearance and bed space for the rotary unit and your typical material sizes.

- Space Availability: Before selecting a rotary axis, assess your workshop layout to ensure there’s enough space for installation, rotation, and maintenance. Table-mounted rotary attachments are compact, offering storage. In contrast, fixed and side-mounted rotary axes require extra space around your machine.

- Controller and Software Support: Check if your controller and software support 4-axis operations. Some setups may require firmware updates or additional driver modules.

- Consider Weight Limits: The rotary axis and the workpiece must be within the CNC router’s load-bearing capacity to avoid mechanical stress or damage to the machine. Heavy or oversized materials may require a fixed or side-mounted rotary axis with independent support, while lighter items can be handled by portable setups.

Budget and Investment Goals

The cost of rotary systems can vary significantly based on size, functionality, and integration level, so it’s necessary to balance your immediate needs with long-term goals.

- Table-Mounted Rotary Attachments: If you’re working with a limited budget or exploring rotary machining for the first time, a table-mounted rotary axis is the most cost-effective solution.

- Fixed Rotary Axis in Front: This option represents a mid-range investment and suits users who regularly work with rotary parts. Offers a good balance between performance, durability, and cost.

- Side-Mounted Rotary Axis: Designed for heavy-duty, high-frequency production, a side-mounted rotary axis comes with a higher price tag. High initial investment, but excellent for long-term scalability and automation readiness.

The best rotary axis for your CNC router depends on a thoughtful balance of your materials, usage frequency, workspace, and budget. Taking these factors into account will help ensure your investment delivers the performance and flexibility your business or projects require.

Summarize

The right 4-axis CNC router setup will not only expand your machining capabilities but also improve productivity and open new possibilities for your business. Table-mounted rotary attachments are ideal for users who need flexibility and work with small, lightweight materials on an occasional basis. Fixed rotary axes in front of the machine offer better stability and are well-suited for regular use and medium-sized cylindrical projects. For heavy-duty or industrial applications, a side-mounted rotary axis provides maximum load capacity and workflow efficiency. By evaluating the key factors mentioned in the article above, you can make an informed decision that aligns with your budget and long-term goals.

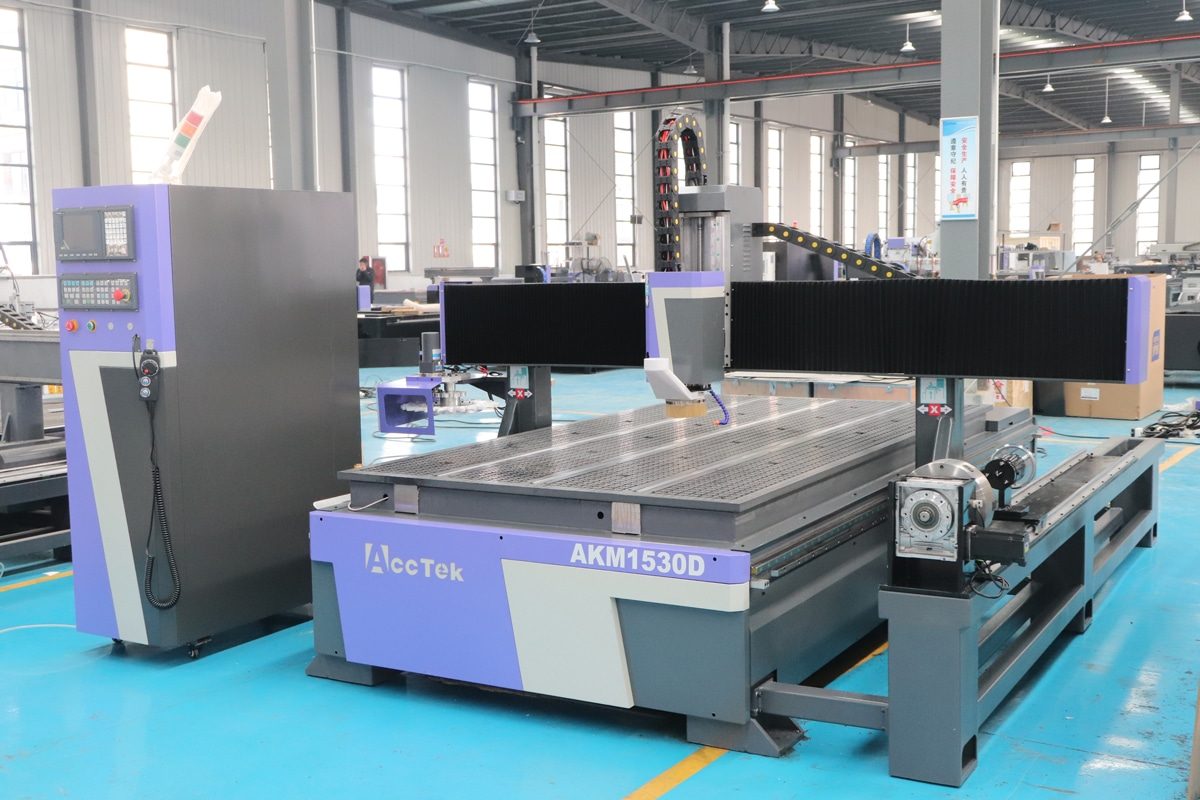

If you’re looking for a reliable and versatile 4-axis CNC router solution, AccTek CNC is an excellent choice. As a professional CNC router manufacturer, AccTek specializes in delivering high-performance machines tailored to meet diverse production needs. From compact CNC routers for small workshops to Industrial CNC routers for heavy-duty tasks, we offer flexible solutions tailored to your material, workspace, and workflow requirements. With a commitment to quality, precision, and customer support, AccTek CNC provides not just machines but long-term value and productivity for your workshop or factory.