- 12-16 Min Read

Acrylic is a widely used material in CNC routing for its excellent clarity, lightweight nature, and ability to produce high-end visual results. It’s a go-to choice for signage, display cases, and decorative panels. However, due to the low melting point and brittle composition of acrylic, it is especially prone to problems like melting from excessive heat and chipping along the edges. These issues can affect both the visual quality and structural integrity of the final product.

Fortunately, these problems are avoidable with the right approach. By understanding how acrylic reacts to cutting forces and heat, and by carefully adjusting your tool selection, spindle speed, feed rate, and cooling strategy, you can achieve smooth, professional-grade cuts. In this article, we’ll explore practical techniques to help you prevent melting and chipping during CNC routing, ensuring clean edges, minimal waste, and consistent results across all your acrylic projects.

Understanding Acrylic Material Properties

To achieve high-quality results when CNC routing acrylic, it is first necessary to understand the specific material properties that influence its behavior during cutting. Acrylic is a transparent thermoplastic known for its excellent clarity and weathering. However, its thermal and mechanical properties also make it challenging to machine without proper preparation.

Thermal Sensitivity

Acrylic has a relatively low softening point, typically around 105°C (221°F), and begins to melt at approximately 160°C (320°F). When cut using a CNC router, friction between the tool and the material can quickly generate heat. If this heat is not dissipated efficiently, the acrylic may begin to melt, leading to gummy residue on the tool, poor edge quality, or even warping. Unlike materials like wood or aluminum, acrylic doesn’t absorb heat well, so it builds up heat rapidly at the point of contact.

Brittleness

Although rigid and structurally stable, acrylic is also brittle. This means it is prone to cracking and chipping under mechanical stress. Chipping is especially common when using dull tools, incorrect feed rates, or if the material isn’t adequately supported.

Cast vs. Extruded Acrylic

- Cast Acrylic: This version is made by pouring liquid acrylic into molds. It has better optical clarity, is harder, more scratch-resistant, and tends to chip less during routing. It also produces smoother edges and is the preferred choice for CNC router work.

- Extruded Acrylic: This type is formed by pushing acrylic through rollers. It is softer, more uniform in thickness, and usually less expensive. However, it is more prone to melting and tends to clog cutting tools more easily due to its lower molecular weight.

Thermal Expansion and Stress

Acrylic expands more than many other materials when heated. Rapid heating during CNC routing can introduce internal stress, causing distortion or stress cracking. Additionally, residual stresses from manufacturing or poor storage conditions can affect how acrylic behaves during machining, sometimes leading to unpredictable fractures or warping.

Surface Hardness

Acrylic has a relatively high surface hardness for a plastic, which helps it resist minor abrasions. However, this also means it can generate more friction when cut with inappropriate tools.

Acrylic’s low melting point, brittle nature, and variations in composition demand a thoughtful approach to CNC routing. When you fully understand how acrylic reacts under mechanical and thermal stress, you can adjust your tooling and techniques accordingly to achieve cleaner, more consistent results.

Choose the Right CNC Tooling

One of the most critical factors in preventing acrylic from melting or chipping during CNC routing is selecting the proper cutting tool. The type, shape, material, and condition of the bit you use directly affect heat generation, chip evacuation, and surface finish.

- Use the Correct Bit Type: For acrylic, O-flute or single-flute upcut bits are generally recommended. These bits are specifically designed for plastics and have a geometry that efficiently removes chips while minimizing heat buildup. Their wide flutes allow chips to escape quickly, reducing the chance of melting due to friction. Double-flute or multi-flute bits are not ideal for acrylic, as they trap heat and generate more friction.

- Ensure Sharpness and Quality: Always use sharp, high-quality bits when CNC routing acrylic. Dull tools increase friction and can cause localized melting, rough edges, or even cracks. Solid carbide bits are a good choice for acrylic because of their durability and ability to maintain a sharp edge under high-speed operation. Additionally, polished flute surfaces help reduce chip adhesion and further limit heat buildup.

- Choose the Right Bit Size and Length: Select a bit with a diameter suitable for your cutting job. Larger bits can remove more material quickly and disperse heat better, while smaller bits are ideal for detailed work but require careful speed control to prevent overheating. Avoid overly long bits unless necessary, as they are more prone to vibration, which can lead to chipping or cracking.

- Consider Specialty Coatings or Bit Designs: Some tools come with coatings or designs that further reduce friction and heat generation. Bits with a mirror-polished finish or non-stick coatings can help prevent melted acrylic from adhering to the flute. Compression bits or bits with chip-breaking features can also be considered in specific cases where edge quality is a priority.

Choosing the right CNC tooling for your acrylic routing project, you create the foundation for smooth, clean cuts and minimize the risk of common machining issues. The right bit doesn’t just improve results—it extends tool life and enhances production efficiency.

Optimize Spindle Speed and Feed Rate

Finding the right balance between spindle speed and feed rate is beneficial for preventing acrylic from melting or chipping during CNC routing. These two settings directly affect heat generation and material stress. By optimizing them correctly, you can ensure smooth, clean cuts without damaging the material.

High Feed Rate + Low RPM

One of the most effective strategies when routing acrylic on a CNC router is using a high feed rate combined with a low to moderate spindle speed (RPM). A faster feed rate moves the cutting bit through the material quickly, reducing the time it spends in contact with any one spot—this helps prevent heat from building up. A lower spindle speed keeps friction to a minimum, further reducing the risk of melting. This combination allows chips to form and evacuate efficiently, instead of turning into sticky strings or fusing to the bit.

Examples of Recommended Settings

While every CNC router and project is different, the following are general starting points that often yield good results for acrylic:

- Spindle Speed: 12,000–18,000 RPM

- Feed Rate: 100–200 inches per minute (IPM), or 2,500–5,000 mm/min

- Pass Depth: Equal to or less than the diameter of the bit

- Chip Load: Approximately 0.005–015 inches per tooth (0.12–0.38 mm)

Using a sharp, single-flute or O-flute bit designed for plastic will also improve chip evacuation and cutting efficiency at these settings.

Trial-and-Error Approach for Fine-Tuning

Because variables like material thickness, acrylic type, and bit size can impact performance, it’s important to fine-tune your spindle speed and feed rate through trial and error. Begin with conservative settings based on recommendations, then gradually adjust while observing the cutting behavior. Look for signs such as melted edges (too much heat), chipping (too aggressive or dull bit), or tool marks (incorrect speed/feed ratio). By carefully testing and recording what works best for your specific CNC router and acrylic type, you’ll build a reliable cutting profile for future projects.

Use Proper Chip Evacuation

Effective chip evacuation is a key factor in preventing acrylic from melting or chipping during CNC routing. When chips aren’t cleared properly from the cutting area, they can trap heat, dull the bit, and even lead to poor surface finishes. To maintain a clean cut and protect the material and tool, focus on the following key areas:

The Role of Chip Clearance in Preventing Melting

Acrylic has low thermal conductivity, which means it doesn’t disperse heat well. As the cutting bit moves through the material, it generates friction and therefore heat. If chips remain in the cutting path, they insulate that heat and prevent it from dissipating. This quickly leads to melting and can cause the acrylic to gum up, stick to the tool, or produce foggy, uneven edges. By ensuring chips are cleared away immediately, you allow heat to escape with them, significantly reducing the chance of thermal damage.

Air Assist or Vacuum System

To maintain optimal chip removal, many CNC router setups incorporate an air assist system or a vacuum extraction unit. Air assist uses a directed stream of compressed air to blow chips away from the bit as it cuts, keeping the work area clear and reducing the risk of heat buildup. A vacuum system, on the other hand, continuously pulls debris away from the cutting surface and into a collection unit, which is especially helpful for larger jobs or enclosed CNC router setups. Both systems help improve visibility, reduce tool wear, and ensure smoother cutting performance.

Avoiding Re-Cutting Chips

When chips remain in the toolpath, the bit may pass over them again, a process known as re-cutting. This is harmful for several reasons: it increases friction, causes additional heat buildup, dulls the cutting edge faster, and can even push the acrylic beyond its brittle limits, resulting in edge chipping or surface cracking. Ensuring that chips are fully evacuated after each pass prevents these issues and maintains the integrity of the material throughout the routing process.

Control Depth of Cut and Passes

When machining acrylic with a CNC router, trying to cut too deep in a single pass may seem faster, but it significantly increases the risk of overheating and material stress. Properly balancing pass depth and tool engagement ensures both smoother finishes and longer tool life. Here are key aspects to focus on:

Importance of Shallow Passes

Acrylic is sensitive to both heat and mechanical pressure. Deeper cuts increase the load on the bit, which raises friction and makes it harder for chips to evacuate effectively. This often results in melted edges or cracked surfaces. To avoid this, it’s recommended to use shallow passes, especially when working with thicker acrylic sheets. This results in more consistent chip formation, less chance of edge melting, and a smoother overall finish. A good rule of thumb is to limit the cut depth to no more than 1x the diameter of the cutting bit per pass (e.g., a 1/8″ bit should not cut deeper than 1/8″ per pass).

Multiple Passes vs. Deep Single Pass

While a deep single pass might seem like a way to save time, it often leads to poor results when cutting acrylic. Deep passes generate more friction, increase the load on the spindle, and trap chips in the cut path, which can result in melted surfaces, tool wear, or even material cracking. In contrast, using multiple, shallower passes gives the CNC router better control, allows heat to dissipate more effectively between cuts, and produces much cleaner edges. The slight increase in cutting time is well worth the quality improvement and reduced risk of failure.

Avoiding Overloading the Bit

Overloading the cutting bit can lead to poor chip evacuation, excessive vibration, premature tool wear, and even tool breakage. When too much material is removed at once, the bit struggles to maintain stability and sharpness, which negatively affects both the cut and the machine. Gradual material removal across multiple controlled passes allows the bit to operate within its performance range and maintains cutting efficiency. This not only protects the tool but also helps maintain consistent results across the entire project.

Balance Speed, Depth, and Material Thickness

The right balance between cutting speed, depth per pass, and material thickness depends on your CNC router’s power, bit type, and acrylic grade. For thicker acrylic sheets, divide the total depth into equal, manageable layers. This allows each pass to efficiently remove material without overloading the tool or causing heat accumulation. Monitoring the machine’s sound and chip behavior during cutting will also help you fine-tune the depth for best results.

Cooling Strategies

When machining acrylic with a CNC router, effective cooling helps prevent the material from melting, sticking to the tool, or distorting due to excessive heat. Here are important aspects of managing heat during CNC router operations:

Use of Compressed Air or Air Assist

One of the most common and effective cooling methods is compressed air or an air assist system. By blowing a constant stream of air directly at the cutting area, you help dissipate heat and remove chips at the same time. This keeps the bit and acrylic cool, prevents chips from melting back onto the surface, and allows for smoother, more controlled cutting. Air assist is especially valuable during high-speed operations or deeper passes, where heat tends to build up quickly.

Mist Cooling Systems

In more demanding applications, a mist cooling system can be used to introduce a fine spray of coolant or water-based fluid to the cutting area. This helps lower the temperature even more effectively than air alone. However, mist systems should be used with caution on acrylic, as too much moisture can cloud the surface or cause fogging. It’s also important to ensure that the coolant is compatible with the type of acrylic being used to avoid chemical damage.

Ensuring Workspace Ventilation

Even when using air-based cooling methods, it’s important to maintain good workspace ventilation. Routing acrylic generates fine plastic particles and potentially irritating fumes, especially when melting occurs. An enclosed CNC router setup should include fume extraction or ventilation fans to keep the work environment safe and clear. Proper airflow also helps regulate ambient temperatures around the cutting area, further supporting stable and consistent cutting conditions.

Cooling Between Passes

Allowing a brief cooling period between passes is another simple but effective strategy. Especially when cutting thicker acrylic or making multiple passes, pausing briefly before starting the next pass gives the material and tool time to cool down. This prevents heat buildup over time and reduces the risk of thermal warping or tool fouling. Some CNC routers can be programmed with dwell times or retract motions between passes to automate this process.

Secure and Support the Material Properly

Because acrylic is both rigid and brittle, even slight movement or stress during CNC machining can lead to edge fractures, dimensional inaccuracies, or poor surface finish. Ensuring that the material remains flat, stable, and well-supported throughout the routing process significantly improves safety, cut quality, and repeatability.

Preventing Vibration and Movement

If the acrylic shifts or vibrates during the cut, the bit can apply uneven force, causing small cracks or chips. To avoid this, always use firm and uniform clamping methods such as toggle clamps, T-slot fixtures, or edge clamps with protective padding. A vacuum table is also highly effective, especially for thin sheets, as it provides full-surface support and eliminates the risk of the material lifting during routing.

Use Protective Backing or Spoilboards

Placing acrylic directly on a metal or uneven table can introduce pressure points or lead to edge blowout. To prevent this, always use a flat, smooth spoilboard to provide consistent backing. For thin or flexible acrylic sheets, adding a protective paper layer or masking film can also help minimize surface scratching and keep the material from shifting under vacuum or clamping pressure.

Maintain Material Flatness

Warped or bowed acrylic will not cut evenly and can result in inconsistent depths or missed toolpaths. Before starting, check that the sheet is flat and level. If necessary, use weights or vacuum hold-down to press it flush against the spoilboard. Even slight lifting can cause the bit to plunge deeper than intended, increasing the risk of melting, tool marks, or breakage.

Common Mistakes to Avoid

Even with the right tools and materials, overlooking small details during CNC routing can lead to frustrating results, especially when working with acrylic. Understanding and avoiding these common pitfalls will help ensure smoother cuts, better edge quality, and a more efficient workflow. Here are some of the most frequent errors users make—and how to avoid them:

- Using the Wrong Type of Bit: One of the biggest mistakes is using bits designed for wood or metal instead of those optimized for plastics. Bits like straight flutes or multi-flute cutters generate excessive friction, which increases the risk of melting. Always use single-flute or O-flute bits specifically designed for acrylic and plastic materials, as they offer better chip evacuation and reduced heat buildup.

- Running the CNC Router Too Slowly: Many users believe that a slower feed rate yields more precision, but with acrylic, this approach often backfires. A slow feed rate combined with high spindle speed allows too much heat to build up, causing the acrylic to melt or stick to the bit. Instead, opt for a high feed rate and moderate spindle speed to keep the tool moving and heat under control.

- Neglecting Chip Removal: Failing to evacuate chips from the cutting path can lead to serious problems. Chips that accumulate around the bit retain heat and can be recut, increasing the chance of melting and tool damage. Always use air assist or vacuum extraction to keep the cutting area clean and cool.

- Cutting Too Deep in a Single Pass: Trying to remove too much material in one pass puts excess pressure on the bit and generates excessive heat. This can lead to chipping, melting, and tool deflection. Always use multiple shallow passes to reduce stress and maintain cut quality, especially for thicker acrylic sheets.

- Improper Material Hold-Down: If the acrylic isn’t properly secured, vibration and shifting can lead to edge chipping, inaccuracies, or even tool breakage. Avoid clamping too loosely or placing the material on an uneven surface. Use vacuum tables, edge clamps, or spoilboards to keep the sheet flat and stable throughout the cut.

- Using Dull or Worn-Out Bits: Dull bits create more friction, which leads to higher cutting temperatures and poor-quality edges. Always check your tools before starting a job, and replace or sharpen bits as needed to maintain clean, smooth cuts.

Avoiding these common mistakes can dramatically improve your CNC acrylic routing results, extending tool life, reducing material waste, and producing higher-quality finished parts with minimal rework.

Summarize

Preventing acrylic from melting or chipping during CNC routing comes down to understanding the material and applying the right techniques at every stage of the process. By paying attention to each of the factors mentioned in the article, from selecting the right drill, optimizing spindle speed and feed rates, to ensuring efficient chip evacuation, shallow cuts, effective cooling, and stable material support, you can achieve clean, precise acrylic cuts. Continue reading “Guide to Optimizing CNC Router Parameters for Diverse Materials” to get cutting suggestions on various materials.

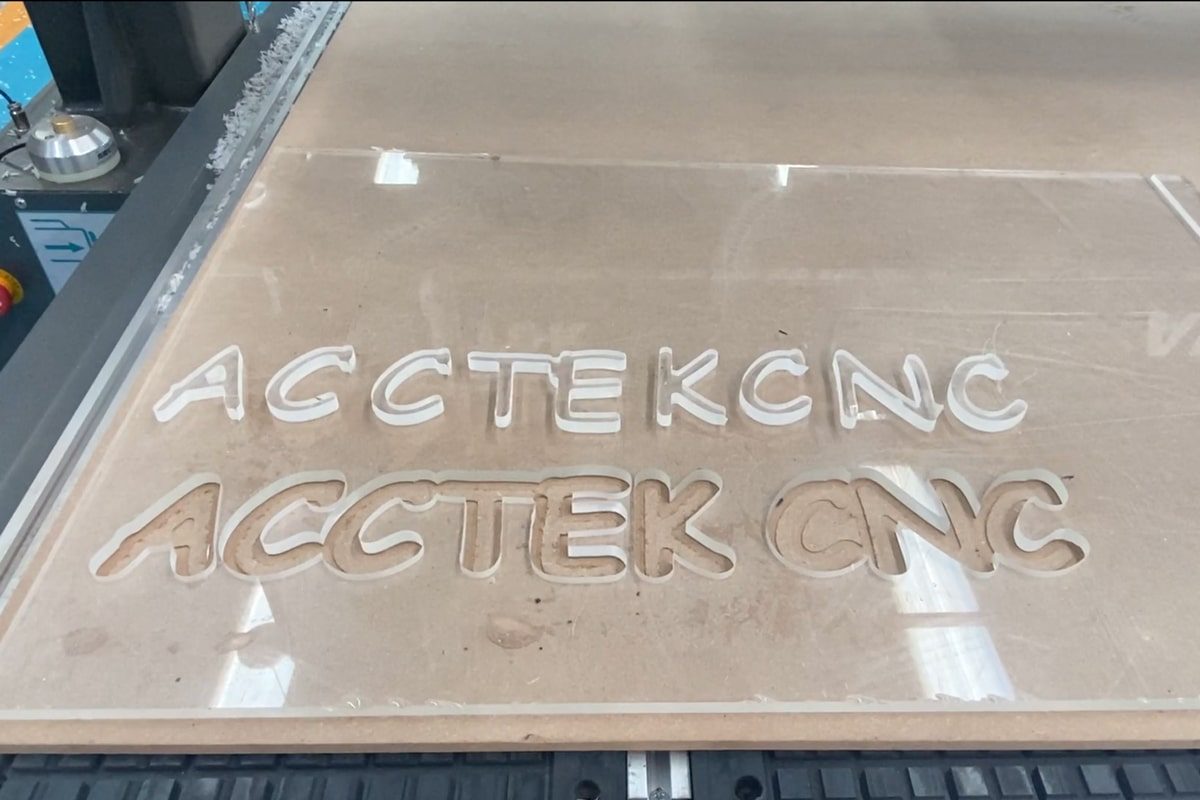

If you’re looking to achieve clean, precise results when cutting acrylic, choosing the right CNC router and support is just as important as using proper techniques. AccTek CNC is a professional CNC router manufacturer offering a wide range of machines specifically designed for materials like acrylic, plastic, wood, and more. We can customize reliable equipment for you with high-speed spindles, vacuum suction cups, and efficient chip removal systems to help you complete various cutting tasks smoothly. Reach out today to get customized CNC router solutions that match your material, budget, and production needs.