- 12-17 Min Read

Choosing the right tool geometry is one of the most critical yet often overlooked factors in CNC routing. The geometry of a cutting tool—its flute design, helix angle, rake angle, and overall structure—directly influences cutting efficiency, surface finish, chip evacuation, and tool life. Even with a high-quality CNC router, using an unsuitable tool geometry can lead to poor edge quality, excessive tool wear, material damage, and unnecessary downtime.

This guide is designed to help CNC router users clearly understand how different tool geometries work and how to choose the most suitable option for specific materials, applications, and machine configurations. Whether you are machining wood, plastics, composites, or soft metals, making informed decisions about tool geometry will improve accuracy, productivity, and long-term machining results.

Understanding CNC Router Tool Geometry Basics

Selecting the right CNC router tool goes far beyond choosing a diameter or brand. Tool geometry plays a key role in how material is cut, how chips are evacuated, and how efficiently a CNC router operates. A solid understanding of tool geometry basics enables operators to achieve better surface finishes, extend tool life, and prevent common machining problems, such as burning, chipping, or excessive vibration.

What Is Tool Geometry?

Tool geometry refers to the specific shape, angles, and structural features of a CNC cutting tool that directly influence its cutting behavior. These geometric characteristics determine how the tool engages with the material, how chips are formed and removed, and how cutting forces are distributed during machining.

Rather than being a single feature, tool geometry is a combination of multiple design elements working together. Each element affects performance differently depending on the material, cutting depth, feed rate, and machine rigidity. Understanding these components allows users to select tools that are optimized for both the application and the CNC router itself.

Key Geometric Elements of CNC Router Tools

Understanding how these geometric elements work together forms the foundation for selecting the right CNC router tool for any application, from woodworking and plastics to aluminum and composite materials. The most important geometric elements to consider when selecting a CNC router tool include:

- Cutting Edge: The sharpened edge that performs the actual cutting. Its sharpness and orientation affect cutting force and finish quality.

- Flutes: Grooves running along the tool that allow chips to escape from the cutting area. The number and shape of flutes influence chip load and heat dissipation.

- Helix Angle: The angle at which the flutes wrap around the tool body. Higher helix angles provide smoother cuts and better chip evacuation, while lower angles offer more stability.

- Rake Angle: The angle of the cutting edge relative to the material surface. Positive rake angles reduce cutting force and are ideal for softer materials, while neutral or negative rake angles improve edge strength.

- Relief (Clearance) Angle: The angle behind the cutting edge that prevents excessive friction between the tool and the workpiece.

- Tool Diameter and Cutting Length: The diameter affects the strength and detail capability, while the cutting length determines the maximum cutting depth and tool stability.

A solid understanding of CNC router tool geometry provides the foundation for selecting the right cutting tools for any machining task. Key geometric elements work together to control chip flow, cutting forces, and surface quality. When these elements are properly matched to the material and machine capabilities, they help reduce wear, prevent defects, and optimize performance. With these fundamentals in mind, users can move forward confidently to explore specific tool geometries and their best applications in real-world CNC routing operations.

Common Types of CNC Router Tool Geometries

CNC router tools come in a variety of designs, each tailored for specific cutting actions, materials, and applications. Understanding the characteristics, advantages, and limitations of each tool type allows machinists to select the most suitable geometry for their project, whether it involves wood, plastics, or soft metals.

Straight Flute Tools

Straight flute tools feature cutting edges that run parallel to the tool’s axis, creating a uniform straight groove along the length of the cutter. This simple design allows for consistent chip removal and straightforward manufacturing.

- Advantages: Excellent for shallow cuts and smooth sidewalls, reduces the risk of splintering on delicate materials, and is easy to sharpen.

- Limitations: Less efficient at chip evacuation compared to spiral flutes, which can cause heat buildup in deeper cuts or harder materials.

- Typical Applications: Straight flute tools are commonly used for cutting wood, MDF, acrylic, and plastics, where precision and minimal tear-out are required. They are ideal for shallow profile cuts, slotting, and engraving tasks.

Up-Cut Spiral Tools

Up-cut spiral tools have helical flutes that spiral upward from the cutting edge to the shank, pulling chips away from the workpiece. The angled flute helps with efficient chip evacuation and prevents clogging during deeper cuts.

- Advantages: Excellent chip removal, reduces heat buildup, allows faster cutting speeds, and is effective for deep cuts.

- Limitations: Can cause slight lifting or splintering on the top surface of the material, especially thin sheets.

- Typical Applications: Up-cut spiral tools are widely used for cutting wood, MDF, plastics, and soft metals, where efficient chip evacuation is required. They are ideal for through-cuts, pocketing, and deep slotting operations.

Down-Cut Spiral Tools

Down-cut spiral tools have helical flutes that push the material downward during cutting. This design keeps the top surface clean and minimizes tear-out while forcing chips down into the cut for removal.

- Advantages: Provides smooth top surfaces with minimal splintering, holds workpieces firmly against the table, and improves edge quality on laminates and veneers.

- Limitations: Chip evacuation is less efficient, which can lead to heat buildup and slower cutting speeds on deeper cuts.

- Typical Applications: Ideal for laminated wood, plywood, acrylics, and delicate materials where the top surface finish is critical. Commonly used for finishing cuts, shallow pockets, and engraving.

Compression Tools

Compression tools combine up-cut and down-cut flutes in a single tool. The upper portion pushes material downward, while the lower portion lifts chips upward, compressing the material in the middle for clean edges on both top and bottom surfaces.

- Advantages: Produces clean edges on laminated and veneered materials, reduces splintering, and is ideal for through-cuts.

- Limitations: Typically more expensive than standard tools and may require slower feed rates for optimal performance.

- Typical Applications: Used extensively for cutting plywood, laminated boards, and veneered materials. Perfect for cabinetry, furniture, and signage applications where both top and bottom edges need a professional finish.

Single-Flute vs. Multi-Flute Tools

Single-flute tools have one cutting edge, while multi-flute tools have two or more edges. The number of flutes affects chip load, cutting speed, and surface finish.

- Advantages: Single-flute high chip removal rate, ideal for plastics and soft materials, reduces heat buildup. Multi-flute smoother surface finish, better for harder materials, can handle higher feed rates.

- Limitations: More flutes reduce chip clearance, increasing the risk of clogging and heat buildup on soft materials.

- Typical Applications: Single-flute tools are ideal for acrylic, plastics, soft wood, and foam. Multi-flute tools are ideal for hardwood, aluminum, and high-precision cutting tasks where a smooth finish is essential.

Selecting the appropriate tool geometry can significantly impact the efficiency, quality, and precision of CNC routing operations. By understanding these tools, users can make informed decisions that match the material and cutting requirements. Proper geometry selection not only improves machining results but also extends tool life and reduces production challenges, making it a fundamental step in successful CNC operations.

Selecting Tool Geometry Based on Material Type

Choosing the right tool geometry depends largely on the material being machined. Ranging from wood and plastics to soft metals and foam, each material responds differently to cutting forces, heat buildup, and chip evacuation. Understanding how tool geometry interacts with the material allows machinists to minimize tear-out, prevent tool wear, and maintain precision.

Wood and Wood-Based Materials

- Solid Wood: When machining solid wood, tool geometry must account for grain direction and the potential for tear-out. Down-cut spiral or compression tools are ideal for minimizing splintering on the top surface, while up-cut tools can be used for efficient chip removal in deeper cuts. Straight flute tools are also suitable for shallow cuts and decorative work, providing smooth sidewalls and precise edges.

- Plywood: Plywood’s layered structure makes it prone to splintering on both the top and bottom surfaces. Compression tools are recommended, as they combine up-cut and down-cut flutes to produce clean edges on both sides. Down-cut spiral tools can also be effective for top surface finish, while careful feed rate control helps prevent delamination during cutting.

- MDF and Particle Board: MDF and particle board are soft, uniform, and dusty materials, requiring tools that promote good chip evacuation. Straight flute or up-cut spiral tools work best, efficiently removing chips and preventing clogging. These materials are forgiving in terms of tear-out, but sharp tools are needed to maintain edge quality.

Plastics and Acrylics

- When cutting plastics and acrylics, tool geometry plays a critical role in preventing melting, chipping, or rough edges. Single-flute spiral tools are ideal for these materials, as they allow efficient chip removal and reduce heat buildup. Up-cut spirals can be used for deeper cuts, while down-cut spirals help achieve a smooth, clean surface on the top layer. Proper selection of spindle speed and feed rate, combined with the right geometry, ensures precise cuts, high-quality finishes, and extended tool life.

Soft Metals (Aluminum, Brass)

- When machining soft metals like aluminum and brass, tool geometry must prioritize efficient chip evacuation and heat control to prevent material welding or tool wear. Single-flute or two-flute up-cut spiral tools with a high helix angle are ideal, as they remove chips quickly while maintaining cutting precision. Proper geometry reduces cutting forces, minimizes vibration, and ensures smooth surface finishes.

Foam and Soft Materials

- Foam and other soft, lightweight materials require minimal cutting forces to prevent tearing or deformation. Single-flute or straight flute tools are recommended, as they provide precise control and clean edges while allowing for smooth chip evacuation. These tools are widely used in prototyping, packaging, and decorative mold-making.

Choosing the appropriate tool geometry based on the material being machined ensures clean cuts, efficient chip removal, and extended tool life. By considering factors such as material hardness, abrasiveness, and surface finish requirements, machinists can select the right flute type, helix angle, and number of cutting edges. Proper geometry selection not only improves productivity and quality but also reduces machining challenges, making it an essential step in successful CNC operations.

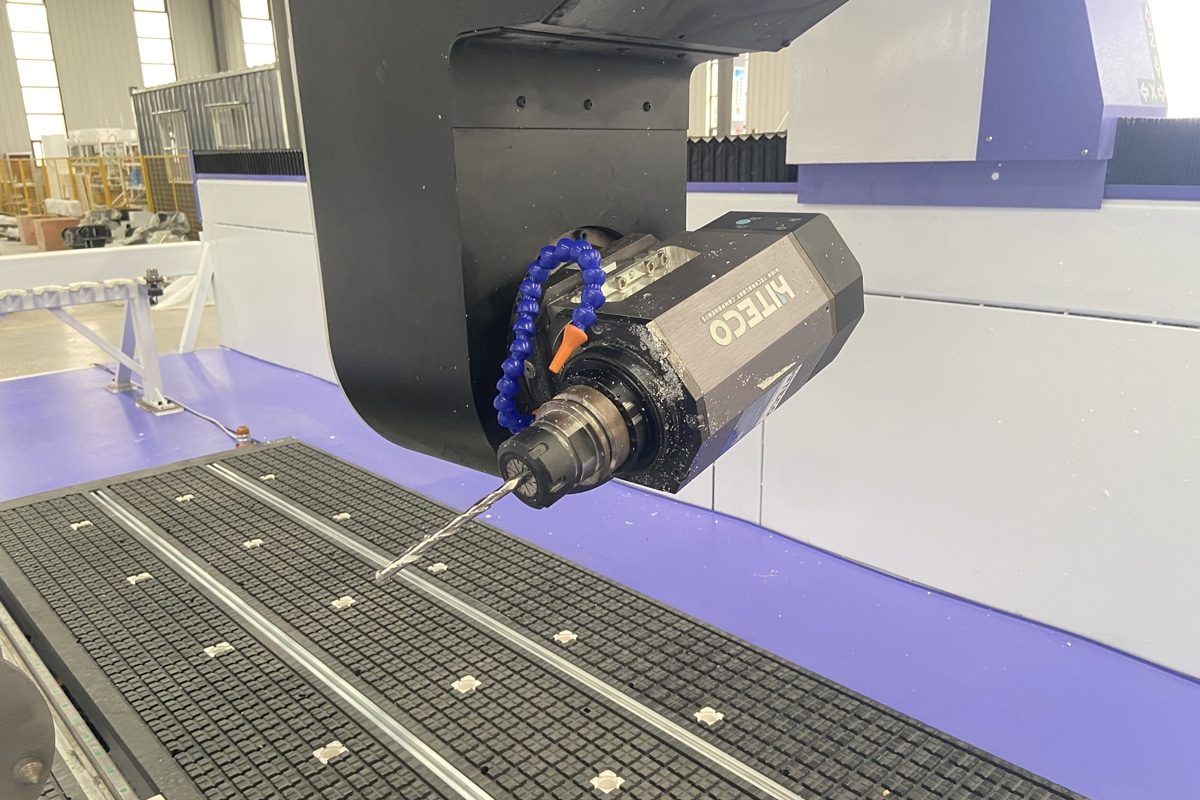

Matching Tool Geometry with CNC Router Configuration

Selecting the right tool geometry is not only about the material being cut but also about how it interacts with the CNC router itself. The machine’s spindle power, workholding setup, and axis configuration all influence which tool geometries will deliver optimal performance. Matching tool geometry to the CNC router ensures efficient cutting, consistent surface quality, and reduced risk of tool or machine damage.

Spindle Power and Speed

The spindle’s power and maximum speed dictate how aggressively a tool can cut. Selecting geometry that matches spindle capability helps prevent tool breakage and protects the machine from excessive wear.

- High-Speed Spindles: They can handle multi-flute tools, steep helix angles, and more aggressive cutting strategies. High-speed, high-power spindles provide sufficient torque to maintain stable cutting forces, even on harder materials, enabling faster feed rates and smoother surface finishes. Using the appropriate geometry with a high-speed spindle maximizes productivity while ensuring precision and consistent part quality.

- Low-Power Machine: Low-power CNC routers have limitations that affect tool selection. Tools with too many flutes or steep helix angles may overload the spindle, causing stalling, vibration, or poor surface finishes. Single-flute or fewer-flute tools with moderate helix angles are better suited for these machines, as they reduce cutting forces, allow efficient chip evacuation, and maintain smooth operation.

Workholding and Vacuum Tables

Tool geometry also affects how the workpiece interacts with the holding method. Proper matching enhances precision, reduces waste, and protects both material and tooling.

- Impact of Tool Geometry on Workpiece Stability: Up-cut spiral tools tend to lift the material during cutting, which can cause thin sheets or lightweight panels to shift if not properly secured. This lifting effect can result in poor edge quality, tear-out, or even part movement during machining.

- Choosing the Right Geometry for Vacuum Tables: Down-cut or compression tools are generally better suited for vacuum tables and delicate workpieces. These geometries push material downward, holding it firmly against the table and minimizing the risk of lifting or splintering. Compression tools, in particular, provide clean edges on both top and bottom surfaces, making them ideal for laminated materials or veneers.

Axis Configuration (3-Axis, 4-Axis, 5-Axis)

The number of axes on a CNC router influences how tool geometry interacts with complex parts. Multi-axis machines, such as 4-axis and 5-axis CNC routers, require tools that provide sufficient clearance and avoid collisions when machining contoured surfaces. Tool length, flute design, and cutting engagement must be carefully considered to maintain stability and consistent material removal. Here is the geometry selection based on axis configuration:

- 3-Axis CNC Routers: Standard tool geometries, such as up-cut, down-cut, or straight flute tools, are generally sufficient for simple profiles, pockets, and through-cuts. Tool selection focuses primarily on material type and depth of cut.

- 4-Axis CNC Routers: Rotational movement introduces additional constraints. Tools must have adequate length and diameter to maintain reach while avoiding interference with the workpiece or rotary axis. Compression or down-cut tools are often preferred for surface finish-sensitive operations.

- 5-Axis CNC Routers: Complex tool paths require short cutting lengths, specialized flute designs, or tapered tools to reduce deflection and vibration. Proper geometry ensures smooth engagement across multi-directional cuts and prevents tool breakage in tight or angled areas.

Properly aligning tool geometry with the CNC router’s configuration ensures stable cutting, precise results, and extended tool and machine life. By considering spindle power, workholding setup, and axis capabilities, operators can select tools that minimize vibration, prevent material lifting or tear-out, and maintain consistent surface quality. Matching geometry to machine configuration is a critical step in achieving efficient, high-quality, and reliable CNC routing operations.

Common Tool Geometry Selection Mistakes

Even with a wide range of CNC router tools available, improper tool geometry selection remains a common cause of poor surface finish, excessive tool wear, and inefficient machining. These mistakes often stem from overlooking material characteristics, machine limitations, or the relationship between tool geometry and cutting conditions. Identifying and understanding these common errors helps operators avoid costly downtime, reduce scrap rates, and achieve more consistent results.

Using the Wrong Flute Type for the Material

One of the most common mistakes is choosing a flute type that does not match the material. For example, using a down-cut tool for deep cuts in plastics or soft metals can lead to chip buildup and overheating, while using an up-cut tool on laminated wood may cause top-surface tear-out. Here is the solution:

Match the flute direction to the material’s behavior. Use down-cut or compression tools for plywood and veneers to prevent splintering, and choose single-flute or low-flute-count tools for plastics to reduce heat buildup and improve chip evacuation.

Ignoring Chip Load Requirements

Failing to consider chip load often results in burning, melting, or premature tool wear. Using too many flutes at high spindle speeds without adjusting feed rates reduces chip size, causing excessive heat instead of proper material removal. Here is the solution:

Select a tool geometry that allows proper chip load based on spindle speed and material type. Reduce the number of flutes on low-power or high-speed machines, and adjust feed rates to ensure chips are formed and evacuated efficiently.

Overlooking Machine Rigidity and Spindle Power

Tool geometry must align with the CNC router’s rigidity and spindle capability. Using aggressive geometries, such as steep helix or multi-flute tools, on low-power or lightweight machines can cause vibration, chatter, or spindle overload. Here is the solution:

Match tool geometry to machine capability. Use single-flute or moderate-helix tools on less rigid machines, and reserve multi-flute or high-helix tools for industrial-grade CNC routers with sufficient spindle power and rigidity.

Prioritizing Tool Cost Over Geometry Suitability

Choosing tools based solely on price rather than geometry suitability can lead to poor performance and higher long-term costs. Choosing lower-cost tools without considering proper geometry often results in poor performance, higher tool wear, and increased production downtime. Here is the solution:

Focus on selecting the correct geometry first, even if the initial cost is higher. Properly matched tools last longer, reduce rework, and improve overall machining efficiency, delivering better long-term value.

Neglecting Workholding Considerations

Ignoring how tool geometry affects workholding can result in part movement or poor edge quality. Up-cut tools can lift thin or flexible materials if vacuum or clamping is insufficient, while the wrong geometry may cause chatter or uneven cuts. Here is the solution:

Consider workholding methods when selecting tool geometry. Down-cut or compression tools are better suited for vacuum tables and thin materials, as they help hold the workpiece firmly in place during cutting.

Avoiding common tool geometry selection mistakes helps maximize CNC routing performance and tool life. By recognizing issues such as mismatched flute types, incorrect chip load assumptions, and ignoring machine rigidity or workholding conditions, operators can make more informed tooling decisions. Correcting these errors leads to smoother cutting, improved surface quality, and more reliable machining outcomes. A thoughtful, application-specific approach to tool geometry selection ultimately enhances productivity and reduces long-term operating costs.

Practical Tips for Optimizing Tool Geometry Selection

Selecting the correct tool geometry is only the first step toward achieving high-quality CNC routing results. To fully benefit from the chosen geometry, operators must also consider real-world factors such as cutting parameters, material behavior, and machine condition. Practical optimization helps bridge the gap between theoretical tool selection and consistent production performance. The following tips provide actionable guidance for selecting and using tool geometries more effectively in daily CNC routing operations.

- Test Tools on Sample Materials: Before full-scale production, always test the selected tool geometry on sample material. Trial cuts help verify edge quality, chip evacuation, and cutting stability, allowing adjustments to be made without risking expensive material or time loss.

- Match Feeds and Speeds to Tool Geometry: Tool geometry directly affects optimal feed rate and spindle speed. Single-flute tools typically require higher feed rates to maintain proper chip load, while multi-flute tools benefit from controlled speeds for smooth finishes. Incorrect feeds and speeds can negate the benefits of proper geometry selection.

- Consider Depth of Cut and Tool Engagement: Deeper cuts place greater stress on tool geometry. Up-cut tools handle deeper cuts better due to superior chip evacuation, while down-cut and compression tools perform best when cutting depths are properly matched to their flute design. Avoid exceeding recommended cutting lengths to prevent deflection or breakage.

- Keep Tools Sharp and Well-Maintained: Even the best tool geometry will perform poorly if the cutting edges are worn or damaged. Regular inspection, proper cleaning, and timely replacement ensure consistent performance and prevent heat buildup, poor surface finish, or excessive cutting forces.

- Balance Surface Finish and Productivity: High-quality surface finishes often require down-cut, compression, or multi-flute tools, while faster material removal favors up-cut or fewer-flute geometries. Choosing the right balance based on production goals improves efficiency without compromising quality.

- Consult Professional Tool or Machine Manufacturers: For challenging materials, complex geometries, or custom applications, professional manufacturers can recommend optimized tool geometries tailored to specific machines and workflows. Expert guidance helps avoid costly mistakes and improves long-term machining reliability.

Optimizing tool geometry selection through testing, parameter adjustment, and proper maintenance can significantly enhance machining outcomes. By carefully matching feeds and speeds to the tool design, monitoring tool wear, and knowing when to use specialized geometries, operators can achieve cleaner cuts, longer tool life, and more reliable production. Applying these practical tips ensures that tool geometry works not just in theory, but effectively on the shop floor—resulting in higher productivity and better overall CNC routing performance.

Summarize

Selecting the right CNC router tool geometry is a critical factor in achieving high-quality cuts, efficient machining, and long-term tool performance. By understanding how different geometries interact with materials, cutting conditions, and machine configurations, operators can reduce errors, improve surface finishes, and extend tool life. Whether working with wood, plastics, soft metals, or composites, a thoughtful approach to tool geometry selection helps optimize productivity and ensures consistent, professional results. Continue reading “How to Choose the Number of Slots in a CNC Router Tool?” to learn more related techniques.

AccTek CNC is a leading manufacturer specializing in professional CNC routers designed to meet the diverse needs of the manufacturing industry. With a strong understanding of tool geometry and material compatibility, we offer machines that cater to a variety of materials, including wood, plastics, metals, and composites. Coupled with excellent customer support and robust after-sales services, AccTek CNC routers provide not only cutting-edge technology but also practical solutions tailored to your manufacturing needs. Choose AccTek CNC for reliable, efficient, and high-performance routers that optimize your production processes and enhance your overall machining capabilities.