- 13-18 Min Read

CNC routers have become essential in woodworking, plastics processing, sign-making, and even light metal fabrication, offering unmatched accuracy and efficiency. However, the true performance of a CNC router depends heavily on the cutting tool it uses—the router bit. These bits come in many shapes, sizes, and designs, each suited to specific materials and applications. Choosing the right bit can mean the difference between clean, precise cuts and wasted material or tool damage.

In this article, we’ll break down the fundamentals of CNC router bits, explore the most common types and their uses, and look at how to match bits to different materials. We’ll also cover best practices, common mistakes, and advanced considerations to help you maximize tool life and achieve better results. Whether you’re a beginner learning the basics or an experienced operator fine-tuning your craft, understanding router bits is key to getting the most from your CNC machine.

Understanding CNC Router Bits

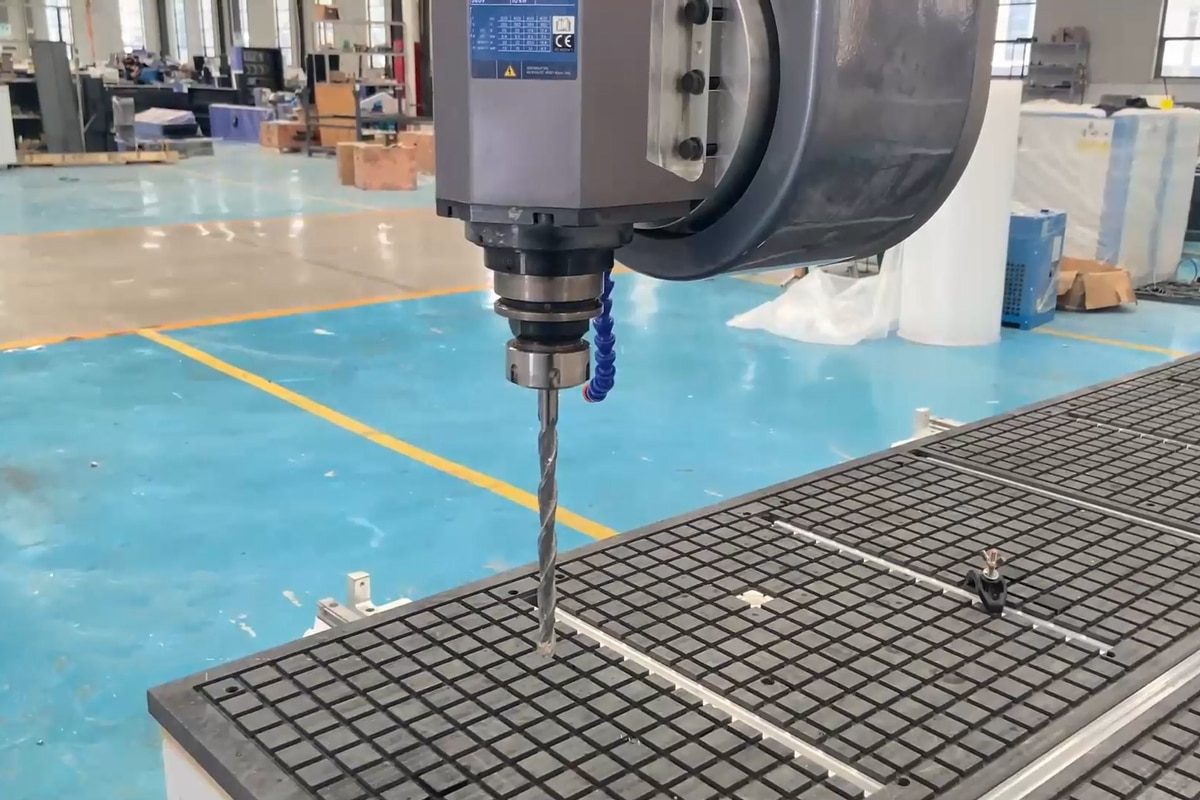

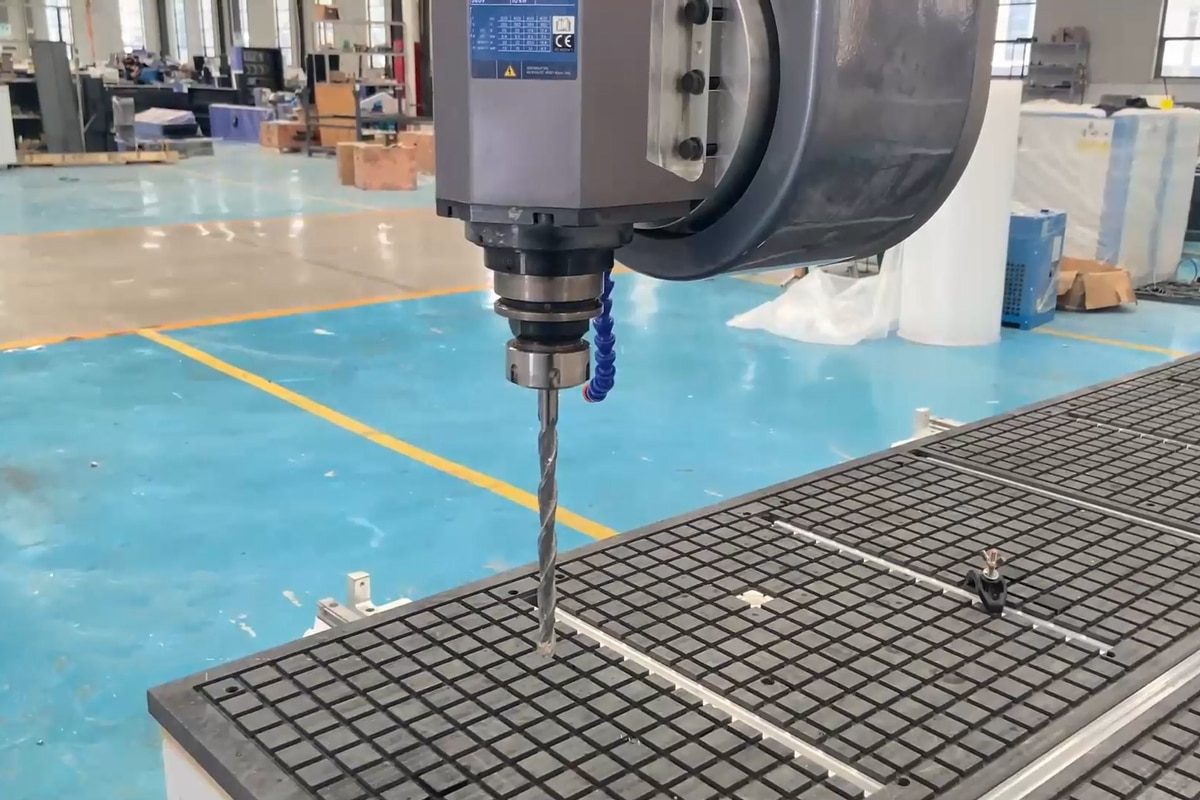

Before exploring the different types of CNC router bits, it’s important to understand what they are and how they work. A CNC router bit is a cutting tool mounted in the spindle of the machine, responsible for shaping, carving, or cutting material according to a programmed toolpath. Each bit is designed with specific geometry to control how it engages with the material, removes chips, and produces a finished surface.

Anatomy of a Router Bit

To make the most of CNC routing, it helps to understand the basic components of a router bit and how each part influences performance.

- Shank: The cylindrical portion that fits into the collet of the CNC router. Common sizes include 1/4″, 1/2″, and 6 mm.

- Cutting Edge / Flutes: The sharpened grooves that actually cut into the material. Their design determines chip removal efficiency and surface finish.

- Tip: The end of the bit can be flat, pointed, or rounded, depending on the type of cut.

- Overall Length and Cutting Depth: Factors that determine how deep the bit can cut and the size of the material it can handle.

Key Factors That Differentiate Bits

Although CNC router bits may look similar, subtle differences in geometry, material, and design greatly affect how each bit performs.

- Material: The material of a CNC router bit determines its strength, durability, and suitability for different workpieces.

- Shape: The shape, or profile, of a router bit dictates the type of cut it can perform.

- Size: The size of a bit, including its shank diameter, cutting length, and overall length, affects stability and reach.

- Coating: Coatings on router bits enhance performance and extend tool life by reducing friction, heat buildup, and wear.

- Cutting Edge Geometry: The cutting edge design affects how the bit engages the material and removes chips.

With a clear understanding of the key components and factors that influence bit performance, operators are better equipped to select the right tool for their projects. This foundational knowledge sets the stage for exploring the different types of bits and their practical uses in CNC machining. In the following section, we will explore the most common types of CNC router bits, explaining their unique designs, practical applications, and the advantages they offer for various machining tasks.

Common Types of CNC Router Bits and Their Uses

CNC router bits come in a wide variety of shapes and designs, each tailored for specific applications. Selecting the right type of bit is beneficial for achieving clean cuts, precise details, and efficient material removal. Below are the most commonly used CNC router bits and their typical uses:

Straight Bits

Straight bits are one of the most basic and widely used CNC router bits. They feature a cylindrical body with straight cutting edges running along the length of the bit, and a flat tip that produces clean, flat-bottomed cuts.

- Uses: Straight bits are ideal for general-purpose cutting tasks such as making slots, grooves, dados, and plunge cuts. They work well in wood, MDF, and plastics, and are commonly used for cabinetry, furniture, and joinery applications.

- Advantages: Easy to use, affordable, and provides consistent cutting depth.

- Limitations: Can cause tear-out on delicate materials if feed rate or depth of cut is not properly controlled.

Spiral Bits

Spiral bits feature helical flutes that wrap around the body of the bit, unlike straight bits. This spiral design allows for smoother cutting, efficient chip evacuation, and reduced material tear-out. Spiral bits are available in three main variations:

- Up-Cut Spiral Bits: Pulls chips upward, providing efficient material removal and deep cuts. Ideal for softwoods, plastics, and other materials where chip removal is important.

- Down-Cut Spiral Bits: Push chips downward, producing cleaner top surfaces. Perfect for plywood, laminates, and veneered materials.

- Compression Spiral Bits: Combine up- and down-cut features, minimizing tear-out on both the top and bottom surfaces of laminated or veneered panels.

Spiral bits are commonly used for slotting, cutting, and finishing work where smooth edges are important. They are also preferred for 3D contouring and precision woodworking.

Ball Nose Bits

Ball nose bits have a rounded tip, unlike flat or V-shaped bits. This design allows the bit to produce smooth, contoured cuts and is ideal for 3D carving, engraving, and surface finishing. The curved tip makes it possible to create detailed contours and complex shapes with precision.

- Uses: Ball nose bits are commonly used in mold-making, sign-making, decorative woodworking, and 3D sculpting. They are perfect for carving rounded edges, creating relief patterns, and machining intricate details in both soft and hard materials.

- Advantages: Smooth finishes on curved surfaces, excellent for intricate designs and detailed engraving.

- Limitations: Not suitable for flat-bottomed cuts or slotting. Cutting speed may need to be reduced for harder materials to avoid tool wear.

V-Bits

V-bits, or V-groove bits, feature a sharp V-shaped cutting edge that allows them to carve angled grooves into material. The tips can be pointed or slightly rounded, depending on the design, making them ideal for precise engraving and decorative cuts. The width of the cut varies with depth, giving versatility for lettering, chamfering, and ornamental patterns.

- Uses: V-bits are widely used in sign-making, decorative woodworking, and engraving projects. They excel at carving letters, logos, and intricate designs into wood, MDF, plastics, and soft metals. They can also be used for chamfering edges to add a finished look to panels and joinery.

- Advantages: Creates sharp, clean lines for engraving and decorative work. Depth-controlled cuts allow variable-width grooves for precision design.

- Limitations: Not ideal for flat-bottomed cuts or deep material removal. Can chip delicate materials if the feed rate and depth are not properly adjusted.

O-Flute Bits

O-flute bits feature a single-flute design with a large, open groove that allows for efficient chip evacuation. Unlike multi-flute bits, the single flute reduces heat buildup and prevents melting when cutting plastics or soft metals. The “O” shape refers to the open flute that optimizes airflow and debris removal during the cut.

- Uses: O-flute bits are ideal for cutting plastics, acrylic sheets, PVC, and soft metals such as aluminum. They are commonly used in signage, prototyping, and fabrication, where smooth edges and minimal melting are critical.

- Advantages: Efficient chip removal and reduced melting or burning in thermoplastics.

- Limitations: Less effective for hardwoods or thick, dense materials. Single-flute design may limit material removal speed compared to multi-flute bits.

Surfacing / Planing Bits

Surfacing or planing bits are large-diameter, flat-bottomed bits designed to quickly flatten and level wide surfaces. They often have multiple cutting edges and are used to remove material evenly over a large area. These bits are useful for preparing raw panels, spoilboards, or uneven stock before more detailed machining.

- Uses: Surfacing bits are commonly used to level spoilboards, flatten raw wood panels, and prepare large materials for precision cutting. They are ideal for woodworking shops and CNC operations that require uniform thickness across panels or large sheets of material.

- Advantages: Quickly creates flat, uniform surfaces. Saves time during material preparation.

- Limitations: Not suitable for detailed or intricate cuts. Requires a powerful spindle and stable setup due to the large diameter and material removal rate.

Specialty Bits

Specialty bits are designed for specific tasks that standard bits cannot perform. They come in various profiles and sizes, each engineered for unique applications such as joinery, engraving, decorative edges, or custom grooves.

- T-Slot Bits: Create T-shaped grooves for fixtures, jigs, or mounting hardware.

- Dovetail Bits: Used in woodworking to make interlocking joints, adding strength and precision to cabinetry or furniture.

- Engraving Bits: Fine-tipped bits for detailed text, logos, or intricate patterns.

- Corner Rounding / Chamfer Bits: Round or bevel edges for decorative finishes or to remove sharp corners.

Each specialty bit serves a very specific function, allowing for advanced joinery, decorative effects, or precision detailing.

Each type of CNC router bit serves a distinct purpose, and selecting the appropriate bit can greatly impact the quality and efficiency of a project. From general-purpose straight bits to specialized engraving or dovetail bits, understanding the strengths, limitations, and ideal applications of each type allows operators to make informed decisions. By choosing the right bit for the material and task at hand, CNC users can achieve cleaner cuts, reduce material waste, extend tool life, and complete projects more efficiently.

Factors to Consider When Choosing a CNC Router Bit

Selecting the right CNC router bit requires careful consideration of multiple factors that directly influence machining quality, efficiency, and cost. The material being cut, the type of cut required, desired finish, and the machine’s capabilities all play a role in determining which bit will deliver the best results. Budget and tool longevity must also be weighed, as the wrong choice can lead to wasted time, poor-quality cuts, and increased expenses. By understanding these key considerations, CNC users can make informed decisions that improve productivity and extend the life of both their tools and machines.

Material Being Cut

Selecting the right CNC router bit depends heavily on the material being machined, as different materials require specific bit designs and cutting strategies to achieve optimal results:

- Wood: Straight bits and up-cut spiral bits work well for general cutting, while down-cut and compression bits are ideal for plywood or veneered boards to prevent tear-out. Hardwoods often require solid carbide bits to maintain sharpness and prevent burning.

- Plastic: Plastics and acrylics are prone to melting and chipping. Single-flute O-flute bits are preferred for smooth cuts and efficient chip evacuation. Maintaining proper feed rate and spindle speed is beneficial to avoid overheating.

- Metal: Non-ferrous metals such as aluminum and brass require stronger, heat-resistant bits, typically solid carbide or carbide-tipped. Cutting metal also demands slower feed rates and appropriate spindle speeds to prevent tool wear and material deformation.

- Composite Materials: Materials like MDF, fiberglass, or carbon fiber are abrasive and can quickly wear standard bits. Coated carbide bits are recommended to resist wear, and compression or spiral designs help reduce delamination and tear-out.

Type of Cut

When selecting a CNC router bit, it’s important to match the bit to the specific type of cut you intend to make. Different bit designs are optimized for different cutting tasks:

- Straight Cuts and Slotting: Straight bits or spiral bits are ideal for creating clean, flat-bottomed cuts, grooves, and slots. These bits remove material efficiently while maintaining consistent depth.

- Angled or Decorative Cuts: V-bits are best for carving angled grooves, decorative patterns, and lettering. The V-shaped tip allows for precise, detailed cuts that vary in width depending on depth.

- 3D Carving and Contouring: Ball nose bits are designed for smooth, rounded cuts, making them perfect for 3D carving, sculpting, and detailed contoured surfaces. Their rounded tip ensures gradual transitions and minimize sharp edges.

- Edge Finishing and Chamfering: Corner rounding or chamfer bits are used to create finished edges, bevels, or rounded corners. These bits improve the aesthetic and functional quality of the workpiece.

Desired Cut Quality

When selecting a CNC router bit, it’s important to consider whether the cut is for roughing or finishing, as each requires different bit characteristics:

- Roughing Cuts: These are used to quickly remove large amounts of material and prepare the workpiece for a final pass. Bits with fewer flutes or up-cut spiral bits are ideal for roughing because they efficiently evacuate chips, reduce heat buildup, and allow faster feed rates. Roughing cuts prioritize speed and material removal over surface smoothness.

- Finishing Cuts: Finishing cuts aim to achieve precise dimensions and a smooth surface finish. Bits with more flutes, sharp edges, or specialized geometries—such as down-cut or compression spiral bits—minimize tear-out and produce cleaner edges. Ball nose bits are commonly used for finishing 3D surfaces, providing smooth contours and detail.

Machine Capability and Speed

Selecting the right CNC router bit also depends on your machine’s performance capabilities and the speed you plan to use. Each CNC router has limits in spindle speed, power, rigidity, and torque, which determine how well it can handle different bit sizes, lengths, and materials.

- Rigidity and Stability: The machine’s structural rigidity affects vibration and chatter during cutting. Less rigid machines may need shorter or smaller-diameter bits for stable performance.

- Spindle Power and Speed: Larger or longer bits, or those cutting harder materials, require higher spindle power and speed for efficient cutting. Insufficient spindle capability can reduce cut quality and cause premature tool wear.

Budget and Tool Longevity

When selecting a CNC router bit, it’s important to balance cost with durability and long-term performance. While higher-quality bits may have a higher upfront cost, they often last longer, maintain sharpness, and provide more consistent results, ultimately saving time and reducing material waste.

- Initial Cost vs. Lifespan: Low-cost bits can be suitable for occasional use or soft materials, but they may dull quickly and require frequent replacement. Investing in solid carbide or coated bits can reduce replacement frequency and improve cut quality over time.

- Durability and Wear Resistance: Bits made from durable materials or with specialized coatings (such as TiN, TiAlN, or DLC) resist heat, abrasion, and corrosion, extending tool life even under heavy use.

In CNC machining, the right router bit makes all the difference between a rough, inefficient process and a smooth, professional-quality finish. Evaluating factors such as material, cut type, surface finish, machine performance, and cost ensures that each job is matched with the most suitable bit. Ultimately, thoughtful selection not only enhances the precision and consistency of the work but also maximizes tool life and machine efficiency. With these considerations in mind, CNC router operators are better equipped to achieve reliable, high-quality results across a wide range of applications.

Best Practices for CNC Router Bit Usage

Even the highest-quality CNC router bit will not perform at its best without proper use and care. To achieve consistent, professional results, operators need to go beyond selecting the right bit—they must also focus on correct installation, optimal cutting parameters, and routine maintenance. Following best practices not only ensures clean, accurate cuts but also extends the life of both the bit and the CNC machine, ultimately saving time and cost in the long run.

- Proper Installation and Tightening: Always ensure the bit is correctly seated in the collet and tightened securely. A loose bit can cause vibration, poor cut quality, or even damage to the machine and workpiece. Using high-quality collets and replacing them when worn is equally important.

- Correct Speeds and Feeds: Match spindle speed and feed rate to the material and bit type. Running too fast can cause burning or chipping, while running too slow can generate excessive heat and dull the cutting edge. Reference material-specific speed and feed charts to optimize results.

- Use the Right Depth of Cut: Avoid overloading the bit by cutting too deeply in a single pass. Instead, use multiple shallower passes to reduce strain on both the tool and the machine while producing cleaner edges.

- Keep Bits Clean and Sharp: Resin, dust, and debris buildup can reduce cutting efficiency and cause overheating. Regularly clean bits with appropriate solutions and sharpen or replace them as needed to maintain precision.

- Store and Handle Bits Properly: Protect bits from damage by storing them in dedicated cases or racks. Handle with care to avoid chipping the cutting edge, especially with carbide bits, which are brittle despite their durability.

- Monitor Wear and Replace Timely: Worn bits produce poor-quality cuts and place unnecessary stress on the machine. Monitor performance and replace bits promptly to maintain accuracy and efficiency.

Adopting proper usage techniques is key to maximizing the performance of CNC router bits. By installing bits correctly, using appropriate speeds and feeds, maintaining sharpness, and handling tools with care, operators can avoid common problems such as poor cut quality, excessive wear, and machine strain. With these best practices in place, CNC router users can work more efficiently, improve the quality of their output, and protect their investment in tools and equipment.

Common Mistakes and How to Avoid Them

Even experienced CNC operators can make mistakes when working with router bits, which can lead to poor cut quality, tool damage, and wasted material. Many of these errors are avoidable with proper knowledge, careful planning, and consistent maintenance. By understanding the most common mistakes, operators can take proactive steps to improve efficiency, extend tool life, and achieve superior results.

Using the Wrong Bit for the Material

A frequent mistake in CNC machining is using a router bit that is not designed for the material being cut. For example, a straight bit may handle softwood but can burn hardwood, melt plastics, or clog when cutting aluminum. Likewise, an O-flute bit designed for plastics will underperform on dense wood. This mismatch can result in poor surface finish, overheating, broken bits, or even machine strain. Here is the solution:

- Identify the material: Determine whether you are cutting wood, plastic, metal, or composite.

- Check bit compatibility: Review manufacturer guidelines to see which bit geometries and coatings are recommended for that material.

- Match the bit design: Use spiral or straight bits for wood, O-flute bits for plastics, and carbide bits for metals.

Running Bits at Incorrect Speeds

Another common mistake CNC users make is running router bits at the wrong spindle speed. If the spindle speed is too high, it can cause excessive heat, leading to burned wood, melted plastics, or dulled cutting edges. Conversely, speeds that are too low may cause chatter, rough surfaces, and inefficient cutting, as the bit struggles to remove material effectively. Both extremes reduce tool life, waste material, and compromise the quality of the finished product. Here is the solution:

- Refer to speed charts: Use manufacturer-recommended spindle speeds based on bit diameter and material type.

- Apply the general rule: Smaller bits require higher speeds; larger bits should run at slower speeds.

- Check material response: If you see burning, melting, or rough surfaces, adjust spindle speed accordingly.

- Run test cuts: Make small test passes to confirm the speed setting before full production.

Cutting Too Deep in One Pass

Attempting to remove too much material in a single pass may seem like a time-saving approach, but cutting too deeply puts excessive stress on the bit and the machine, often causing vibration, chatter, or broken bits. It can also lead to rough edges, poor surface finish, and increased wear on both the tool and spindle. Here is the solution:

- Check maximum recommended depth: Review the bit manufacturer’s specifications for depth per pass.

- Plan multiple passes: Break down deep cuts into several shallower passes.

- Start with roughing passes: Remove bulk material first, then use finishing passes for precision.

- Adjust feed rate: Reduce feed slightly for deeper passes to prevent overloading the bit.

Ignoring Tool Wear and Maintenance

Over time, bits accumulate resin, dust, and debris, or their edges simply wear down. Using a dull bit increases cutting resistance, generates heat, produces rough surfaces, and places unnecessary strain on the machine. Neglecting maintenance can also lead to broken bits or damaged workpieces, increasing downtime and costs. Here is the solution:

- Inspect bits regularly: Check for dull edges, chips, discoloration, or resin buildup.

- Clean bits after each use: Remove resin, dust, and debris using a suitable cleaner.

- Sharpen or replace worn bits: Do not continue using a bit that compromises cut quality.

- Monitor cutting performance: Look for signs like increased heat, rough surfaces, or unusual vibrations.

- Store bits properly: Use protective cases or racks to prevent accidental damage.

- Keep spares on hand: Having replacement bits ready reduces downtime during production.

By being aware of these common mistakes and following practical strategies, CNC router operators can prevent costly errors and maximize productivity. Implementing these best practices ensures cleaner cuts, longer-lasting tools, and safer, more reliable operations, ultimately elevating the quality and efficiency of every project.

Summarize

CNC router bits are essential tools that determine the precision, efficiency, and quality of every machining project. Understanding the anatomy of bits, the factors that differentiate them, and the specific applications of each type empowers operators to select the right tool for the job. Equally important is considering material type, cut requirements, machine capabilities, and proper usage practices to maximize performance and tool life. By following best practices and avoiding common mistakes, CNC users can achieve cleaner cuts, improved efficiency, and consistent results across a wide range of materials and projects. Continue reading “How to Prevent CNC Router Bit Damage?” to keep your router bit in top condition.

For those seeking reliable and high-performance CNC routers, AccTek CNC stands out as a trusted choice. With a wide range of machines designed to handle different materials and applications, AccTek provides solutions suitable for industries ranging from woodworking and signage to plastics, metals, and composites. In addition to high-quality machinery, we offer comprehensive support, including training and technical assistance, ensuring customers can maximize the performance and lifespan of their equipment. Whether you’re exploring 2D cutting, 3D carving, or specialty applications, AccTek CNC delivers reliable tools to help you achieve professional results every time.