- 8-12 Min Read

CNC routers have become essential tools in modern manufacturing, offering versatility, precision, and efficiency across various industries. One particularly popular application is in the creation of custom signage and lettering. From intricate business logos to large-scale commercial signs, CNC routers provide the capability to cut, carve, and engrave a wide range of materials with exceptional detail. With the growing demand for personalized designs and branding, businesses and craftsmen are increasingly turning to CNC routers to meet their creative needs.

In this article, we will explore how CNC routers are applied in the sign-making process, discuss their design considerations, and highlight the benefits they bring to businesses and designers looking to create custom signage. Whether you’re a small business owner looking to create eye-catching storefront displays or a sign-making professional, understanding the capabilities of CNC routers will open new doors for innovative, high-quality signage solutions.

Understanding CNC router and its significance

What is a CNC router?

A CNC router is a computer-controlled machine used for cutting, carving, engraving, and shaping a wide variety of materials, such as wood, plastic, metal, foam, and composites. Unlike manual cutting tools, a CNC router operates automatically, following precise instructions from a digital design file (CAD/CAM). This allows it to reproduce intricate shapes and patterns with exceptional accuracy and repeatability.

CNC routers come in various sizes, from compact desktop versions suitable for small projects to large industrial machines capable of handling heavy workloads. They are widely used across industries such as manufacturing, woodworking, furniture making, sign-making, and prototyping. The CNC router’s versatility lies in its ability to perform tasks like 2D cutting, 3D carving, engraving, and drilling with minimal human intervention, making it a popular choice for businesses and craftsmen seeking precision and efficiency.

The Significance of CNC Routers in Sign Making

In sign making, CNC routers become an important tool, capable of producing custom signs and lettering with high levels of detail, precision, and consistency. The ability to cut materials like wood, acrylic, and metal into both 2D and 3D designs makes a CNC router ideal for creating everything from simple storefront signs to complex art installations. CNC routers allow sign makers to experiment with various fonts, textures, and patterns, providing opportunities for greater creativity and personalization. Businesses increasingly demand unique and eye-catching signage to stand out, and CNC routers empower sign makers to meet these needs efficiently.

Moreover, CNC routers ensure consistency across multiple pieces, making them invaluable for large signage projects that require identical results. They also reduce labor costs and production time, as the automation minimizes manual input and speeds up processes. Whether producing engraved plaques, dimensional letters, or illuminated signs, CNC routers provide a versatile and reliable solution, giving sign makers the flexibility to offer custom designs with fast turnaround times. In an industry driven by innovation, precision, and personalization, CNC routers are indispensable tools that elevate the craftsmanship and efficiency of modern sign-making businesses.

Application of CNC Router in Sign Making

CNC routers are widely used in the sign-making industry, offering precision, efficiency, and versatility across various types of signage. From creative indoor decorations to large-scale outdoor branding, these machines handle intricate designs with ease. Below is an overview of how CNC routers are applied in four key areas of sign making:

Indoor Signage and Decoration

CNC routers are perfect for creating custom interior signs and decorative elements, such as nameplates, plaques, wall art, and directional signs. With the ability to carve intricate patterns into wood, acrylic, or metal, these machines are often used for personalized office signage or artistic installations in restaurants and hotels. Their precision allows for 3D lettering, engraved surfaces, and decorative designs that enhance the aesthetics of interior spaces, contributing to a unique customer experience.

Outdoor Signage and Branding

For outdoor applications, CNC routers enable the production of durable, weather-resistant signs that promote brand identity. Materials like aluminum, acrylic, and wood are commonly used to create illuminated signs, dimensional letters, and logo signs for storefronts. The CNC router’s ability to cut complex shapes ensures businesses can stand out with custom-made signs that reflect their branding. Additionally, CNC routers are ideal for producing large outdoor signs, such as billboards and monument signs, with consistent quality.

Retail Display and Exhibition

CNC routers play a significant role in retail and exhibition design, helping brands create engaging product displays and promotional stands. These machines can cut precise, eye-catching elements for retail shelves, kiosks, and window displays. In exhibitions and trade shows, CNC routers allow companies to build unique signage, 3D logos, and modular booth structures that attract attention. The ability to work with various materials gives businesses the flexibility to experiment with different styles and layouts.

Architectural Signage and Road Signs

In architecture and infrastructure projects, CNC routers are used to produce structural signage, facade elements, and building directories. They also play a role in creating precise road signs and directional signage, which requires accuracy and durability. CNC routers can engrave or cut materials like metal, acrylic, and composite panels to create signs that meet regulatory requirements while maintaining aesthetic appeal. Their efficiency ensures quick production and consistency for large-scale projects, such as public spaces and transportation hubs.

These four applications highlight the versatility of CNC routers in sign making, helping businesses and designers create innovative signage solutions that are functional, attractive, and durable.

Design Considerations for CNC Routing Signs and Lettering

Creating effective signage and lettering with CNC routers requires careful attention to both technical and aesthetic aspects to ensure precision, durability, and visual impact. Below are the key design considerations for CNC routing signage and lettering:

Material Selection

- Choose the Right Material: The choice of material impacts the appearance, durability, and application of the sign. Common materials include wood (for rustic or decorative signs), acrylic (for modern, sleek designs), and metals like aluminum (for outdoor use).

- Thickness and Strength: Ensure the material’s thickness is suitable for the intended design and application. Thicker materials are ideal for outdoor signs to withstand environmental exposure, while thinner materials may be better for indoor signage.

- Cutting Compatibility: The material should be compatible with the capabilities of the CNC router to prevent issues like chipping or burning.

Design Software Compatibility

- File Formats: CNC routers require design files from CAD/CAM software, typically in formats like DXF, STL, or G-code. Make sure the design software used (such as AutoCAD, Vectric Aspire, or Fusion 360) is compatible with the CNC router’s control system.

- Tool Path Generation: Ensure the software supports tool path planning to optimize cuts and reduce processing time. Some software can simulate the cutting process, helping avoid errors before production.

- Design Precision: Software compatibility with the CNC router ensures that fine details, such as engravings or intricate patterns, are accurately transferred from the digital design to the final product.

Font Selection and Typesetting

- Font Clarity and Readability: Use clear, easy-to-read fonts, especially for directional or informational signage. Avoid overly intricate fonts for small letters, as these can lose clarity when routed.

- Letter Height and Spacing: Larger fonts ensure visibility from a distance, especially for outdoor signs. Consider appropriate letter spacing (kerning) to avoid crowding or gaps that can affect readability.

- Depth and Detailing: If engraving is involved, plan for the depth of the cuts to enhance visibility while maintaining the integrity of the material.

Mold and Processing Parameters

- Cutting Speed and Feed Rate: Adjust the CNC router’s speed and feed rate according to the material type to avoid chipping or burning. Softer materials require faster speeds, while harder materials may need slower, more precise cuts.

- Tool Selection: Use the appropriate CNC router bits based on the material and design. For example, V-bits are ideal for engraving, while flat-end mills work best for cutting dimensional letters.

- Layering and Multiple Passes: Complex designs or thicker materials may require multiple passes to achieve the desired depth without damaging the material. Optimize tool paths to ensure smooth cuts and reduce production time.

By focusing on material selection, software compatibility, font choice, and processing parameters, sign makers can ensure high-quality results when using CNC routers. Proper planning and execution not only enhance the visual appeal and durability of signage but also streamline production, reducing errors and waste.

Benefits of Using a CNC Router to Make Signs and Lettering

CNC routers provide several advantages for sign makers, offering precision, versatility, and efficiency. Below are the key benefits of using a CNC router for creating custom signs and lettering:

Precision and Accuracy

- CNC routers follow detailed digital design files (CAD/CAM), ensuring high precision with exact cuts and smooth edges, resulting in professional, high-quality signs.

- The ability to replicate complex designs, intricate patterns, and fine lettering ensures consistent quality across multiple signs.

- Automated routing reduces the risk of human error, ensuring each piece is created precisely as intended, even for delicate or intricate fonts.

Versatility and Flexibility

- CNC routers can cut, carve, and engrave a wide range of materials, including wood, plastic, metal, foam, and acrylic, creating diverse types of signage.

- This versatility allows sign makers to cater to different client needs, from indoor decorative signs to durable outdoor signage, without changing production methods.

- They support 2D cutting and 3D carving, allowing sign makers to create flat signs, raised lettering, or sculpted designs with the same machine.

- CNC routers are adaptable to different industries, whether for retail displays, business branding, architectural signage, or road signs, providing flexibility to meet diverse needs.

Efficiency and Productivity

- Automated operation allows CNC routers to produce signs faster than manual cutting methods, minimizing labor costs and reducing production time.

- Batch production becomes easier with CNC routers, as they replicate designs accurately without requiring constant supervision. This ensures the timely completion of large orders for commercial clients.

- Tool path optimization minimizes material waste, helping businesses reduce costs and increase overall production efficiency. Errors are also minimized since the machine follows precise instructions from design files.

Customization and Personalization

- CNC routers offer endless creative possibilities, allowing sign makers to experiment with unique fonts, patterns, and textures that align with customer preferences or branding requirements.

- Custom 3D lettering, engraved logos, and intricate decorative elements are easily achievable, empowering businesses to differentiate their products with innovative, eye-catching designs.

- With digital design files, quick modifications can be made to accommodate last-minute changes or personalized requests, providing sign makers with greater flexibility to meet individual customer needs.

Using a CNC router for signage and lettering provides businesses with the tools to achieve superior precision, versatility, efficiency, and customization. These benefits not only enhance the visual impact of signage but also streamline production processes, helping sign makers deliver high-quality, personalized products with speed and consistency.

CNC Routing Best Practices and Tips for Sign Production

Using a CNC router effectively for sign production requires a combination of careful planning, proper setup, and adherence to best practices. Below are some essential tips to ensure high-quality results:

Material Handling and Fixing

- Secure Material Properly: Use clamps, vacuum tables, or adhesive tapes to hold the material firmly in place. Proper fixation prevents shifting during cutting, ensuring accurate results.

- Prevent Warping or Bending: Thinner materials may warp under pressure. Use spoil boards or add support underneath to keep the material flat.

- Material Alignment: Ensure the material is aligned correctly with the router’s origin to avoid misaligned cuts, especially for multi-piece signs or layered lettering.

Tool Maintenance and Replacement

- Use the Right Bit for Each Job: Different router bits are suited for specific materials and tasks. Use V-bits for engraving, ball-nose bits for 3D carving, and flat-end mills for cutting flat surfaces. Ensure the bit is appropriate for the material type to prevent chipping or burning.

- Inspect Bits Regularly: Dull or damaged bits lead to rough edges and increased wear on the machine. Replace bits as needed to maintain cutting precision and reduce downtime.

- Clean Bits After Use: Remove debris and residue from bits to prolong their lifespan and prevent overheating during future cuts.

Dust and Chip Removal

- Use a Dust Collection System: CNC routing generates significant dust and debris, especially when cutting wood or plastic. A dust collection system helps maintain a clean work environment and improves safety.

- Regularly Clear Chips During Operation: For long cuts, pause periodically to remove accumulated chips that could affect cutting accuracy. Some CNC routers support air-blasting systems to keep the cutting area clear in real-time.

- Protect Machine Components: Excess dust buildup can interfere with the CNC router’s mechanical parts, reducing performance. Keep rails, spindles, and bearings clean and lubricated for smooth operation.

Quality Control and Inspection

- Check Cut Depth and Dimensions: Use calipers and depth gauges to ensure the cuts meet design specifications, especially for intricate lettering and logos.

- Inspect Edges for Cleanliness: After CNC routing, check for burrs or rough edges. Sand or trim edges to achieve a polished, professional finish.

- Conduct Final Product Inspection: Verify that all pieces fit together properly if the sign requires assembly. Ensure letters and shapes align correctly for readability and aesthetics before shipping or installation.

By following these best practices, sign makers can achieve precise, efficient, and high-quality results when using CNC routers. These techniques not only improve the output but also enhance the longevity of the CNC router and reduce production delays, resulting in a smoother workflow and satisfied clients.

Summarize

CNC routers have proven to be invaluable tools in the creation of custom signage and lettering, offering a blend of precision, versatility, and efficiency. Their ability to work with a variety of materials, produce intricate designs, and ensure consistent quality makes them ideal for applications ranging from indoor decorations to large-scale outdoor branding. As the demand for high-quality, creative signage continues to grow, CNC routers will remain an essential part of modern sign-making, helping artisans and manufacturers push the boundaries of design and deliver exceptional results. Continue reading “What Industries Are CNC Routers Used In” to learn more about the application areas of CNC routers.

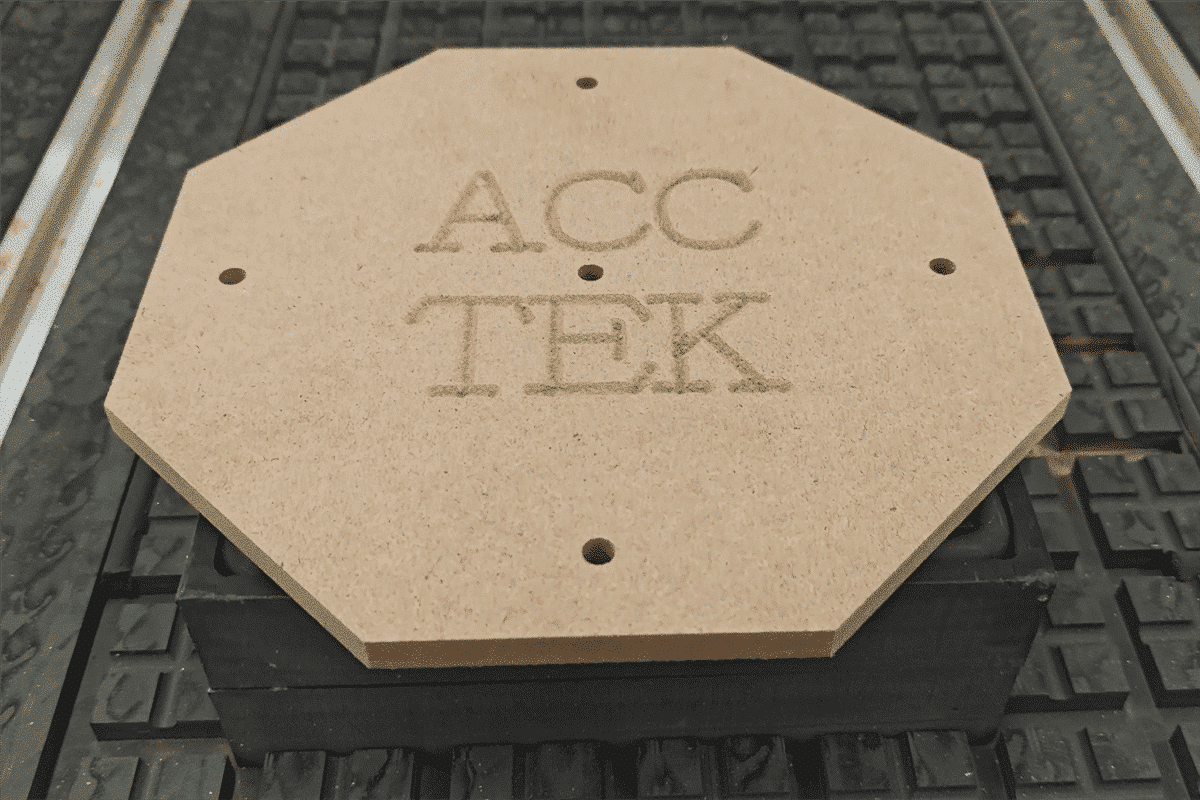

AccTek CNC is a well-known CNC router manufacturer in China, renowned for delivering high-quality machines designed to meet the needs of modern sign makers. With a focus on precision, versatility, and efficiency, our CNC routers empower businesses to produce custom signage and lettering with ease. By offering advanced automation and reliable performance, AccTek CNC helps businesses streamline production while maintaining consistent quality across projects. AccTek CNC is your trusted partner for efficient and precise CNC routing solutions.